Challenger Terra Gator 3244 Chassis. Manual - part 98

Page 31

4. A piece of thin shim stock ~0.0254mm (0.001”) is

to be inserted in several places around the

diameter to check the ring gear is properly seated.

5. Install (2) bolts, nuts and washers, for safety.

An optional assembly method is as follows if a press

is not used:

1. Apply a light coat of grease to the O-Ring.

2. Install the O-Ring into the groove of the planetary

ring gear face. Care should be taken not to twist or

damage the O-Ring during assembly.

3. Apply a light coat of oil to the outer diameter edge

of the planetary ring gear that will be pressed into

the spindle flange bore.

4. Set the spindle over the planetary ring gear and

O-Ring already assembled and align the holes in

the spindle flange with the planetary ring gear

spacing by using 1 or 2 temporary guide pins that

fit the M18 holes.

CAUTION

Do not use a steel hammer, use a rubber or

rawhide mallet.

5. Using a rubber or rawhide mallet, Not Steel

hammer,tap the spindle over the planetary ring

gear by hitting around the spindle flange several

times until ring gear is seated.

6. Remove the temporary guide pins.

7. A piece of thin shim stock ~0.0254mm (0.001”) is

to be inserted in several places around the

diameter to check the ring gear is properly seated.

Wheel Hub, Inner Bearing Spacer,

Wheel Bearings, Seal, and Spindle

Sub-Assembly

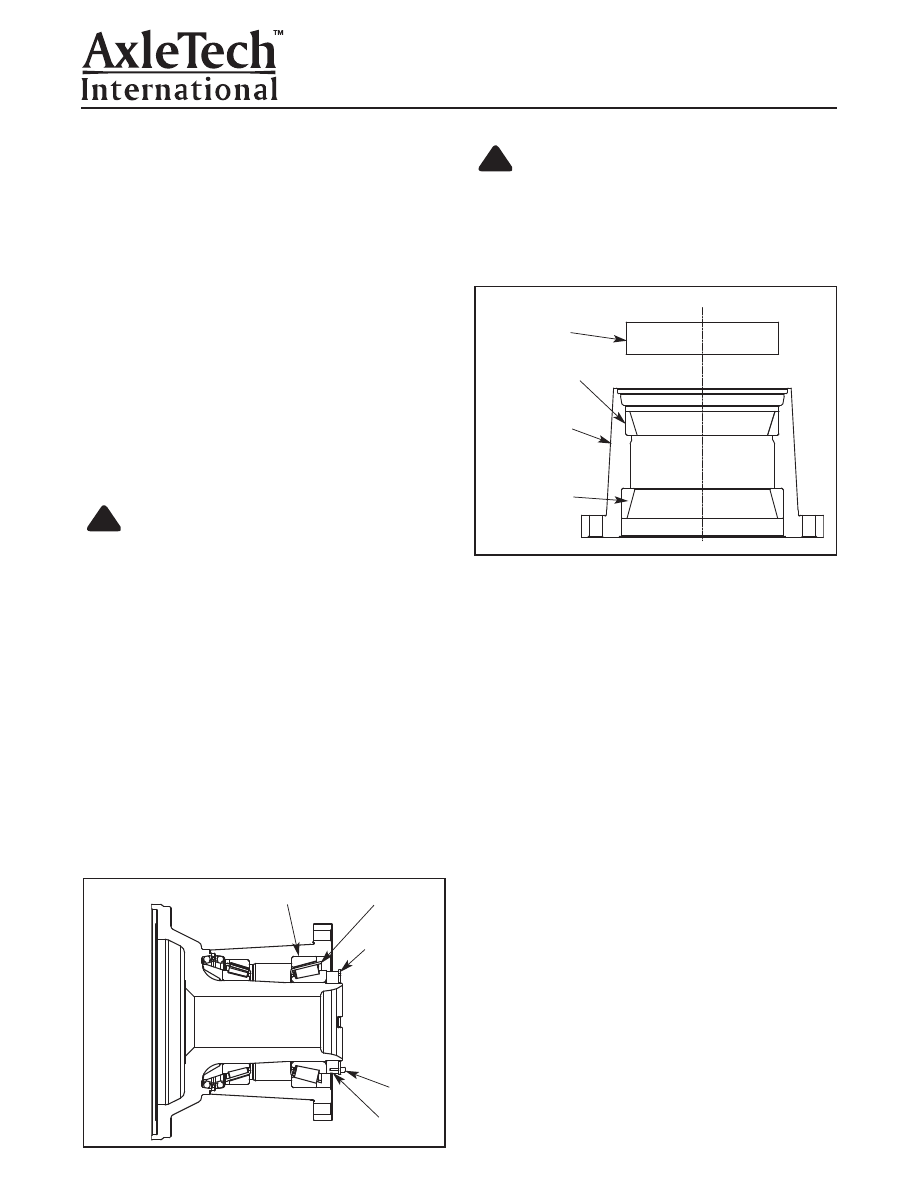

If the wheel hub,spindle, and bearings were

disassembled during disassembly, the following

procedure is recommended. Figure 4.15.

!

WARNING

Observe all warnings and cautions provided by

the press manufacturer to avoid damage to

components and serious personal injury.

1. Place the wheel hub upright in a press to install the

bearing cups. Figure 4.16.

2. Press each bearing cup into the wheel hub against

the shoulder in the wheel hub by using the appropri-

ate bearing cup drivers, tool number 2 and 3 (see

Special Tool Section).

3. A piece of thin shim stock ~0.0254mm (0.001”) is

to be inserted in several places around the diame-

ter to check the bearing cups are properly seated.

4. Remove the wheel hub from the press and place

on suitable workbench for further safe assembly.

NOTE:

The inner bearing cone must be installed in

the wheel hub and not on the spindle bearing

diameter because the Duo Cone seal, once installed

in the wheel hub assembly will not fit over the bearing

cone assembly.

5. Apply a light coat of oil to the inner bearing cone

rollers and install in the wheel hub assembly.

6. If the wheel bearing spacer was previously

removed, apply Adhesive #Q58-Grade -226 or

#Q44 to the spindle face of the bearing spacer.

Figure 4.17.

!

Figure 4.16

Figure 4.15

Section 4

Assembly

OUTER BEARING CUP

BEARING

CONE

LOCKPLATE

CAPSCREW

ADJUSTING NUT

PRESS TOOL

BEARING CUP

WHEEL HUB

BEARING CUP