Aprilia scooter (manual) - part 11

-

REAR TOP BOX LIGHT SWITCH TEST

-

Raise the saddle and check continuity across the two terminals with a multimeter set to the Ohm range.

Correct reading when switch is released (saddle raised) : 0 ohm

Correct reading with switch pressed (saddle closed):

ohm

-

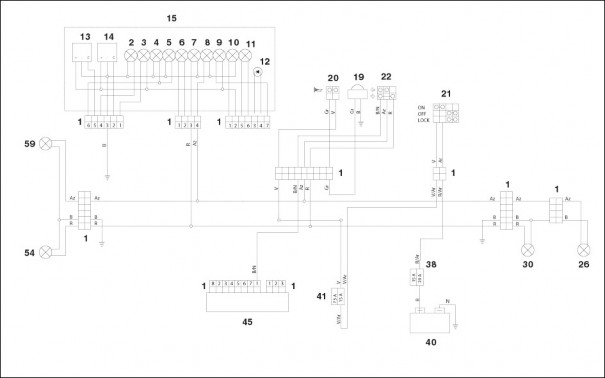

LIGHT CIRCUIT

-

LIGHT CIRCUIT

-

Key:

2. High beam light

-

Parking lamp light

-

Dashboard backlighting bulbs

15. Complete dashboard

18. Left switch

21. Key-operated switch

27. Parking light/left brake light

29. Parking light /right brake light

32. Number plate light

38. Main fuses

-

Battery

-

Auxiliary fuses

-

High beam lamp

-

Low beam lamp

-

Parking light

-

Complete headlight

TROUBLESHOOTING

-

Check battery condition, 2.4.1.

-

Check fuse condition, 8.12.1.

-

Check the light switch

-

Check the bulbs, 8.11.1.

SWITCH TEST

-

-

Check switch continuity using a multimeter.

-

Change any switch that operates other than as specified in the relevant diagram.

Light switch

Wires

V

N

Bi

V

PAS

-

VISUAL AND ACOUSTIC SIGNALS

-

VISUAL AND ACOUSTIC SIGNALLING SYSTEM

-

Key:

-

Right indicator light

-

Left indicator light

15. Complete dashboard

-

Warning horn

-

Horn button

-

Key-operated switch

-

Direction indicator switch

26. Rear left direction indicator

30. Rear right direction indicator

38. Main fuses

-

Battery

-

Auxiliary fuses

45. CDI control unit

54. Front right direction indicator

DIRECTION INDICATOR TROUBLESHOOTING

-

-

Check that the bulbs are in good condition, 8.11.1.

-

When one bulb is burnt out, the other bulb will flash at doubled frequency.

-

Check the direction indicator switch.

-

Check the CDI control unit and replace if needed,

7.2.2.

The flasher is incorporated into the CDI control unit.

WARNING HORN TEST

-

Feed 12 Volts to the two connectors of the waning horn.

-

If the horn does not operate, adjust through the adjuster.

-

Replace the horn if necessary.

SWITCH TEST

-

Check switch continuity using a multimeter.

-

Change any switch that operates other than as specified in the relevant diagram.

Direction indicator switch

Wires

B/N

Az

r

Left direction indicator

Right direction indicator

Horn button

Wires

Gr

V

ON

OFF

-

BULB REPLACEMENT

-

BULB REPLACEMENT Read 1.2.1., 1.7.1. carefully.

-

WARNING

WARNINGBefore proceeding to change a bulb, rotate the

ignition switch to “ ”.Wear clean gloves or use a clean, dry cloth to handle bulbs. Do not put your fingerprints on a bulb, as this may cause overheating leading to failure. If you touch a bulb with your fingers, remove any fingerprints with alcohol to avoid early failure. DO NOT PULL ON THE WIRING.

-

-

Place the vehicle on the stand.

NOTE Check the fuses before changing a bulb, 8.12.1.

PARKING LIGHT BULB

To replace:

-

Remove the front cover, 7.1.10.

WARNING

WARNINGProceed carefully.

Do not damage the tabs and/or their recesses.

-

Rotate and extract the bulb holder working from the rear end of the bulb holder.

-

Extract the bulb.

NOTE Make sure the locating pegs locate properly into the holder when fitting the bulb.

-

Fit a new bulb of equal rating.

HIGH AND LOW BEAM BULBS

To replace:

Open the glove compartment (1) and unhook the side guides pressing moderately down.

-

Grasp the bulb connector (2) and pull to disconnect.

-

Twist the bulb holder (3) anticlockwise and extract from the reflector seat.

-

Extract the bulb.

On refitting:

NOTE Insert the bulb into the reflector seat and ensure that the three pegs on the bulb match the slots in the reflector seat.

-

Position the bulb holder (3) into the reflector seat and twist clockwise.

-

Connect the bulb connector (2).

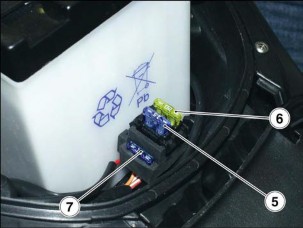

TAIL LIGHT BULBS

The tail lights accommodate:

-

Two parking light/brake light bulbs (4).

-

Two rear direction indicator bulbs (5).

NOTE The following procedure applies to both indicators.

To replace:

-

-

Unscrew the two retaining screws (6) and remove the lens (7).

WARNING

WARNINGProceed carefully.

Do not damage the tabs and/or their recesses.

-

Rotate anticlockwise and extract the bulb (4, parking/brake light) or (5, direction indicator).

-

Fit a new bulb of equal rating.

NOTE On refitting, ensure the lens (7) locates properly into its seat.

WARNING

WARNINGProceed carefully.

Do not damage the tabs and/or their recesses.

-

Tighten the screws (6) gradually. Do not overtighten or you will damage the lens (7).

FRONT DIRECTION INDICATOR BULBS

-

Remove the front cover, 7.1.10.

-

Working from the front end of the vehicle, rotate the holder (8) with the bulb (9) clockwise and extract both.

-

Press the bulb (9) moderately and twist anticlockwise.

-

Extract the bulb.

NOTE Make sure the locating pegs locate properly into the holder when fitting the bulb.

-

Fit a new bulb of equal rating.

TAIL LIGHT BULB

-

Grasp the bulb holder (10), pull and extract.

-

Remove the bulb and fit a new bulb of equal rating.

DASHBOARD BULBS

-

Remove the dashboard, 7.2.6.

-

Rotate the bulb holder clockwise and extract.

-

Extract the bulb – which is the bayonet type – and replace it.

-

Insert the bulb holder and rotate clockwise to lock it in place.

CLOCK BATTERY REPLACEMENT

-

Remove the dashboard to give access to the rear end,

7.2.6.

-

Release the click-opening door.

-

Change the button battery.

-

Refit the click-opening door.

-

REPLACING THE FUSES

-

REPLACING THE FUSES

WARNING

WARNING

-

Never attempt to repair a defective fuse.

Never use a fuse of a rating other than specified.

This could damage the electrical system or cause a short circuit, with the risk of fire.

NOTE When the fuses fitted in a particular position keep blowing frequently, there might be a short circuit or overloading.

Checking the fuses is recommended whenever an electrical component fails to operate or is malfunctioning, or when the engine does not start.

Check the 3-A and 15-A fuses first and then the 30-A fuses.

-

-

Set the ignition switch to “ ”. This will prevent accidental short circuits.

Main fuses:

-

Perform the first four steps described at paragraph

2.4.3.

Auxiliary fuses:

-

Remove the front cover, 7.1.10.

Inspection:

-

Extract all fuses one by one and check for blown fuses. A blown fuse is identified by the link bar in the centre being divided.

-

When you find a blown fuse, determine and rectify the cause (if possible) before fitting a new fuse.

-

Replace any failed fuse with a fuse of equal current rating.

NOTE When you use one of the spare fuses, remember to add a new fuse of equal rating to the fuse box.

Layout of auxiliary fuses (front cover):

- 15-A fuse (1)

From ignition switch to: lights, horn, brake lights.

- 7.5-A fuse (2)

From ignition switch to: starting interlock relay, automatic starter.

- 7.5-A fuse (3)

Spare.

- 15-A fuse (4)

Spare.

Layout of main fuses (battery compartment):

- 20-A fuse (5)

From battery to: ignition switch, helmet compartment light.

- 15-A fuse (6)

From battery to: power socket.

- 15-A fuse (7)

Spare.

10 m

8.13. BEAM SETTING

This is a quick beam inspection procedure. Place the vehicle ten metres away from a vertical wall. It is important that the motorcycle be on level ground.

Switch on the low beam and sit astride the vehicle. The light spot on the wall should be just below the horizontal line of the headlight (about nine/tenths of overall height).

To set beam height:

-

Open the glove compartment (1) and unhook the side guides by pressing moderately downwards.

-

Use a screwdriver and rotate the lower adjuster screws

(2) of both beams:

TIGHTEN (turn clockwise) to lower the beam. SLACKEN (turn anticlockwise) to raise the beam.

![]()

8.13.2. BEAM HORIZONTAL SETTING

To adjust the horizontal position of the beam:

-

Open the glove compartment (1) and unhook the side guides by pressing moderately downwards.

-

Use a screwdriver and rotate the upper adjuster screws (2) of both beams:

TIGHTEN (turn clockwise) to move the beam to the right (viewed in the direction of travel);

SLACKEN (turn anticlockwise) to move the beam to the left; (viewed in the direction of travel).

![]()

-

WIRING DIAGRAM

-

WIRING DIAGRAM

-

Key:

WIRE COLOUR CODING

|

1. |

Multi-pin connectors |

Ar |

Orange |

|

2. |

High beam warning light |

Az |

Light blue |

|

3. |

Low fuel light |

B |

Blue |

|

4. |

Parking light warning light |

Bi |

White |

|

5. |

Dashboard backlighting bulbs |

G |

Yellow |

|

6. |

Check light (not in use) |

Gr |

Grey |

|

7. |

Right direction indicator repeater light |

M |

Brown |

|

8. |

Left direction indicator repeater light |

N |

Black |

|

9. |

Oil pressure light |

R |

Red |

|

10. |

ABS light (not in use) |

Ro |

Pink |

|

11. |

Side stand light |

V |

Green |

|

12. |

Anti-theft system LED (not in use) |

Vi |

Purple |

|

13. |

Coolant temperature indicator |

||

|

14. |

Fuel level indicator |

||

|

15. |

Complete dashboard |

||

|

16. |

Coolant thermistor |

||

|

17. |

Oil pressure sensor |

||

|

18. |

Left light switch |

||

|

19. |

Warning horn |

||

|

20. |

Horn button |

||

|

21. |

Key-operated switch |

||

|

22. |

Direction indicator switch |

||

|

23. |

Starter button |

||

|

24. |

- |

||

|

25. |

Engine kill switch |

||

|

26. |

Rear left direction indicator |

||

|

27. |

Parking light/left brake light bulb |

||

|

28. |

- |

||

|

29. |

Parking light/right brake light bulb |

||

|

30. |

Rear right direction indicator |

||

|

31. |

- |

||

|

32. |

Number plate light |

||

|

33. |

Front brake light switch |

||

|

34. |

Rear brake light switch |

||

|

35. |

Brake light/starting interlock relay |

||

|

36. |

Starter relay |

||

|

37. |

Starter motor |

||

|

38. |

Main fuses |

||

|

39. |

Power socket |

||

|

40. |

Battery |

||

|

41. |

Auxiliary fuses |

||

|

42. |

HT coil |

||

|

43. |

Spark plug |

||

|

44. |

Automatic starter |

||

|

45. |

CDI control unit |

||

|

46. |

Side stand switch |

||

|

47. |

Pick-up |

||

|

48. |

Generator |

||

|

49. |

Voltage regulator |

||

|

50. |

Thermal switch |

||

|

51. |

Fan |

||

|

52. |

Rear top box light switch |

||

|

53. |

Rear top box light |

||

|

54. |

Front right direction indicator |

||

|

55. |

High beam bulb |

||

|

56. |

Low beam bulb |

||

|

57. |

Parking light |

||

|

58. |

Complete headlight |

||

|

59. |

Front left direction indicator |

||

|

60. |

Fuel sensor |

||

|

61. |

Ignition relay |

UPDATES 9

SUMMARY

-

UPDATE 3

-

REFERENCE MANUALS 3

-

TECHNICAL DATA 4

-

LUBRICANT CHART 6

-

ROUTINE MAINTENANCE TABLE 7

-

CARBURETTOR SPECIFICATIONS 8

-

CHECKING AND TOPPING UP TRANSMISSION OIL LEVEL 9

-

-

UPDATE

-

REFERENCE MANUALS Version 125 cc

SPARE PARTS CATALOGUES

aprilia part# (description) 6642 rel.03

Version 250 cc

SPARE PARTS CATALOGUES

aprilia part# (description) 6642 rel.03

SPECIAL TOOLS CATALOGUES

aprilia part# (description) 001 M

SPECIAL TOOLS CATALOGUES

aprilia part# (description) 001 M

OWNER'S MANUALS

aprilia part# (description)

8104853

8104854

8104856

ENGINE TECHNICAL MANUAL

OWNER'S MANUALS

aprilia part# (description)

8104853

8104854

8104856

ENGINE TECHNICAL MANUAL

aprilia part# (description)

8140680

8140681

8140682

8140683

8140684

aprilia part# (description)

8140797

8140798

8140799

8140800

8140801

-

TECHNICAL DATA

DIMENSIONS

Max. length 2085 mm (82.086 in)

Max. width 785 mm (30.905 in)

Max. height (front part of the fairing included) 1370 mm (53.937 in) Seat height 790 mm (31.102 in)

Wheel base 1460 mm (57.480 in)

Wheel base 1480 mm (58.267 in)

Min. ground clearance 190 mm (7.480 in)

Unladen weight (in the direction of travel) 162 kg (357.148 lb)

Unladen weight (in the direction of travel) 170 kg (374.785 lb) ENGINE

Make M 245 M

Make M 237 M

Type Single-cylinder, four-stroke with four valves, wet forced lubrication, overhead camshaft.

Number of cylinders 1

Total displacement 124 cm3 (7.567 in3)

Total displacement 244 cm3 (14.890 in3)

Bore/stroke 57 x 48,6 mm (2.244 x 1.913 in)

Bore/stroke 72 x 60 mm (2.835 x 2.362 in)

Compression ratio 12,0 ± 0,5: 1

Compression ratio 11,0 ± 0,5: 1

Starting Electric

Engine idling rpm 1600 ± 100 giri/min

Clutch Centrifugal type

Gearbox Automatic

Cooling system Liquid-type (50% water + 50% coolant), with forced circulation

Valve clearances Intake 0.10 / Exhaust 0.15 CARBURETOR

Model CVK 7 30 KEIHIN

Model WVF 7 0 29 WALBRO

FUEL SUPPLY

Type Vacuum pump

Fuel Premium-grade petrol, min. O.N. 95 (N.O.R.M.) and 85 (N.O.M.M.)

CAPACITY

Fuel (with reserve) 9,5 liters

Fuel reserve 1,5 liters

Engine oil

-

changing engine oil only 1000 cm3 (61.024 in3)

-

changing engine oil and engine oil filter 1100 cm3 (67.126 in3)

-

changing for engine overhaul 1150 cm3 (70.177 in3)

Transmission oil 150 cm3 (9.154 in3)

Coolant 1.200 cm3 (73.228 in3)

Seats 2

Vehicle max. load (rider + passenger + luggage) 210 kg (462.970 lb) TRANSMISSION

Variator Continuous automatic

Primary With V-belt

Secondary Gear-type

Engine/wheel total ratio

- short 1:29,40

- long 1:8,78

Engine/wheel total ratio

- short 7:19,30

- long 1:6,80

FRAME

Type

Single-beam with twin overlapped cradle

Steering inclination angle

27°

Trail

104 mm (4.094 in)

SUSPENSIONS

Front

telescopic fork with hydraulic operation

Stroke

105 mm (4.134 in)

Rear

n. 1 Hydraulic monoshock

Stroke

105 mm (4.134 in)

BRAKES

Front

Hydraulic disc brake - 0 240 mm (9.449 in)

Rear

Hydraulic disc brake - 0 190 mm (7.480 in) (combine with front brake)

WHEELS

Front

E - 13 x 3,00 DOT - D

Rear

E - 13 x 3,50 DOT - D

TYRES

Type

Tubeless

Front

110 / 90 - 13" 56 P

Rear

130 / 70 - 13" 63 P

Front

Rear

200 kPa (2,0 bar)

INFLATION PRESSURES FOR CARRYING A

220 kPa (2,2 bar)

PASSENGER

Front

230 kPa (2,0 bar)

Rear

250 kPa (2,2 bar)

IGNITION

Type

Capacitive discharge, variable spark advance

Timing advance

Variable, controlled by the ECU5°/min - 24°/>4000 rpm

Timing advance

Variable, controlled by the ECU4°/min - 15°/4000 -6000 rpm

SPARK PLUG

Standard

NGK CR 8 EB

As an alternative

NGK CR 7 EB

NGK CR 9 EB

CHAMPION RG 6 YC

CHAMPION RG 4 HC

Electrode gap

0,7 - 0,8 mm (0.028 - 0.031 in)

ELECTRIC SYSTEM

Battery

12 V - 12 Ah

Fuses

20 - 15 - 7,5 A

Generator (with permanent magnet)

12 V - 180 W

Generator (with permanent magnet)

12 V - 235 W

BULBS

Low beam

12 V - 55 W

High beam

12 V - 55 W

Parking light

12 V - 16 W

Direction indicators

12 V - 10 W

Tail lights/Number plate light/ Stop light

12 V - 5 W / 21 W

WARNING LIGHTS

Instrument panel lights

12 V - 1,2 W

Direction indicators

12 V - 1,2 W

Engine oil pressure

12 V - 1,2 W

Low beam

12 V - 1,2 W

High beam

12 V - 1,2 W

Fuel reserve

12 V - 1,2 W

d

-

-

LUBRICANT CHART

LUBRICANT

PRODUCT

Engine oil

RECOMMENDED: SUPERBIKE 4, SAE 5W - 40 or

4T

FORMULA RACING, SAE 5W - 40.

4T

FORMULA RACING, SAE 5W - 40.As an alternative to the recommended oils, it is possible to use select oilshaving properties in compliance with or even above A.P.I. SJspecifications.

Transmission oil

RECOMMENDED: F.C., SAE 75W 90 or

GEAR

SYNTH, SAE 75W

- 90.

GEAR

SYNTH, SAE 75W

- 90.As an alternative to the recommended oil, use select oils having propertiesin compliance with or even above A.P.I. GL3 specifications

Fork oil

RECOMMENDED: F.A. 5W or F.A. 20W, as an alternative

FORK

5W or FORK 20W.

FORK

5W or FORK 20W.Should you wish to reach an average behavior between those offered by

F.A.

5W and by

F.A.

5W and by  F.A.

20W or

F.A.

20W or  FORK

5W and by

FORK

5W and by  FORK

20W, mix the products as follows:

FORK

20W, mix the products as follows:SAE 10W =

F.A.

5W 67% of the volume, +

F.A.

5W 67% of the volume, + F.A.

20W 33% of thevolume.

F.A.

20W 33% of thevolume. FORK

5W 67% of the volume +

FORK

5W 67% of the volume +  FORK

20W33%

of the volume.

FORK

20W33%

of the volume.SAE 15W =

F.A.

5W 33% of the volume, +

F.A.

5W 33% of the volume, + F.A.

20W 67% of thevolume.

F.A.

20W 67% of thevolume. FORK

5W 33% of the volume +

FORK

5W 33% of the volume +  FORK

20W67%

of the volume.

FORK

20W67%

of the volume.Bearings and other lubrication points

RECOMMENDED: BIMOL GREASE 481 +

GREASE

SM2.

GREASE

SM2.As an alternative to the recommended product, use select oil for rollingbearings, useful temperature range -30°C.+140°C (-22°F.+284°F), dripping point 150°C.230°C (302°F.446°F), highly anticorrosive, water and oxidization resistant.

Battery terminals

Neutral grease or vaseline.

Brake fluid

RECOMMENDED: F.F. DOT 4 (DOT 5 compatible) -

BRAKE

BRAKE5.1 DOT 4 (DOT 5 compatible).

As an alternative to the recommended fluid, use fluids having properties incompliance with or even above SAE J1703, NHTSA 116 DOT 4, ISO 4925specifications.

NOTE Before mixing different makes or types of oil, check theircompatibility.

Engine coolant

RECOMMENDED: ECOBLU - 40° C (-40°F) +

COOL.

COOL.As an alternative to the recommended fluid, use fluids having properties incompliance or even above basic ethylene glycol CUNA NC 956-16specifications.

NOTE Use only nitrite-free anti-freeze and corrosion inhibitors with afreezing point of -35°C (-31°F) as a minimum.

-

ROUTINE MAINTENANCE TABLE

Parts After running-in

[1000 km (621 mi)]

Every 6000 km

(3728 mi) or 8 months

Every 12000 km

(7456 mi) or 16 months

Idle misture (CO) - 1 -

Belt, converter rollers and plastic guides - 1 3

Converter belt - 3 -

Steering bearings 1 1 -

Wheel bearings - 1 -

Converter cover air filter - 2 -

Secondary air scoop filter - 2 -

Clutch shoes - - 1

Valve clearance - 1 -

Brake fluid 1 1 1 / every 2 years: 3

Front fork oil 1 1 3

Engine oil filter mesh and magnetic screw 1 1 -

Converter rollers and plastic guides - 1 3

Wheels/tyres - 1 -

Nuts and bolts torque 1 1 -

Cylinder head nuts torque 1 - -

Brake bleeding 1 - -

Battery terminals tightening 1 - -

Fuel line - 1 every 2 years: 3

Rear shock absorbers 1 1 -

Battery - Battery fluid level 1 1 -

Spark plug 1 1 3

Carburettor - idle rpm 4 - 1

Air cleaner - 2 -

Engine oil filter 3 3 -

Throttle operation 1 1 -

Brake operation 1 1 -

Converter grease - 3 -

Brake light switch - 1 -

Coolant 1 every 1000 km (621 mi): 1 / every 16

months: 3

Engine oil 3 every 1000 km (621 mi): 1 / every 6000

km (3728 mi): 3

Transmission oil 3 every 6000 km (3728 mi): 1 / every 24000

km (14913 mi): 3

Beam setting/operation - 1 -

Tyres/inflation pressure every month: 1

Battery terminals tightening 1 - -

Front fork 1 1 -

Brake pads wear 1 every 2000 km: (1250 mi): 1

1 = check and clean, adjust, lubricate or change, if necessary; 2 = clean; 3 = change; 4 = adjust.

Perform the maintenance operations more often if the vehicle is used in rainy or dusty areas, on uneven surfaces or on racetracks.

(

)

= OPERATIONS TO BE MADE ALSO BY THE USER

)

= OPERATIONS TO BE MADE ALSO BY THE USER

-