Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 955

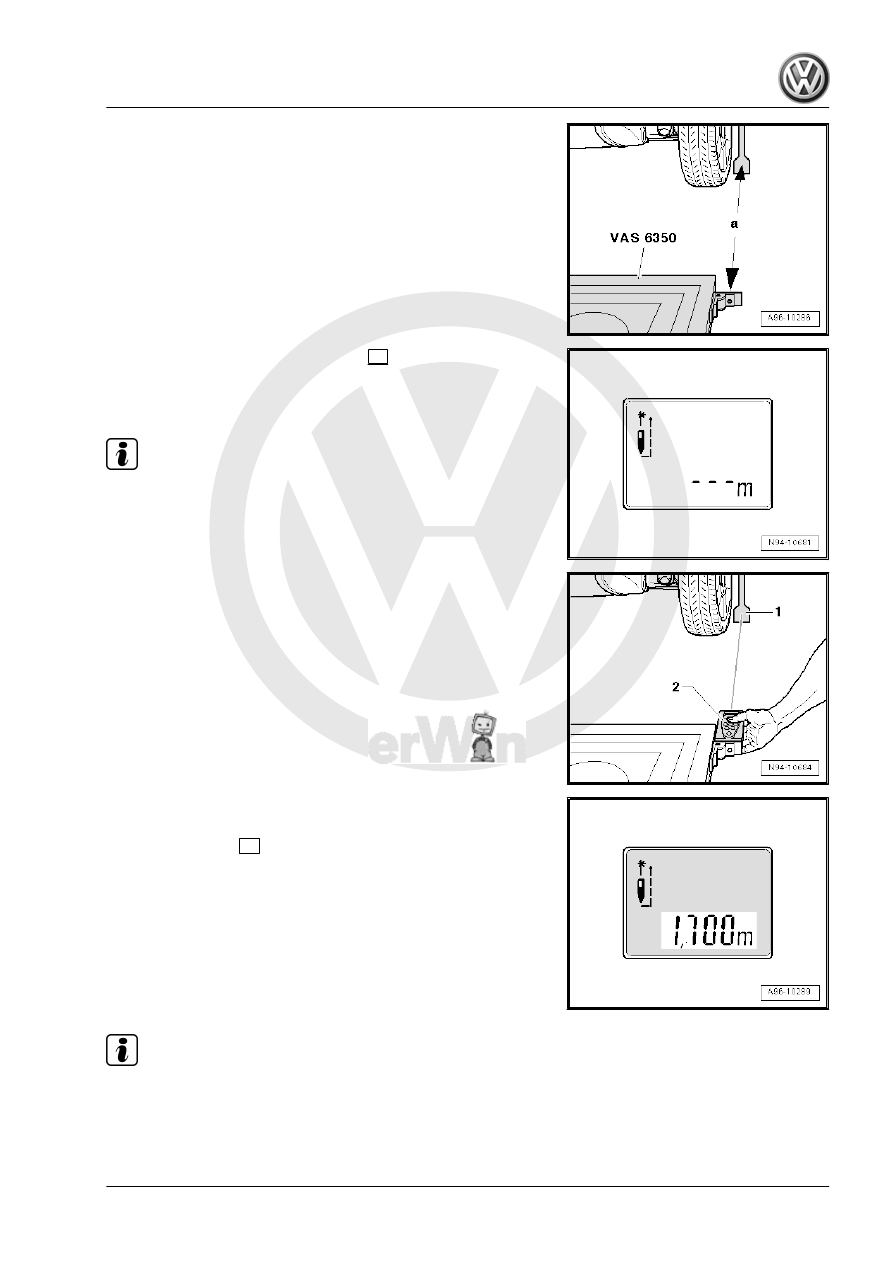

– Position the -VAS6350A- at distance -a- to the rear wheels.

• Dimension -a- = 1700 ± 2 mm

– Switch on the -VAS6350/2- with the

ON

button.

Display on the -VAS6350/2- :

• “- - - m”

Note

The laser is switched on at same time.

– Hold the -VAS6350/2- -2- flush against the catch bracket, as

shown in the illustration, for the distance measurement.

• The -VAS6350/2- must lie firmly against the catch bracket.

– Make sure the “laser beam” for the distance measurement

contacts the paddle on lower enlarged part -1-.

If that is not the case, correct the measuring paddle height using

the locking nuts on the -VAS6350/1- .

– Briefly press the

ON

button for distance measurement.

Display on the -VAS6350/2- :

• “1,700 m” (specified value: 1700 ± 2 mm).

– Repeat the measurement procedure from the left catch brack‐

et to measuring paddle on left rear wheel.

• The distance value must be the same on both sides.

If both measured values are not the same, adjust the -VAS6350A-

accordingly.

Note

The vehicle in the illustration is only a basic outline.