Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 863

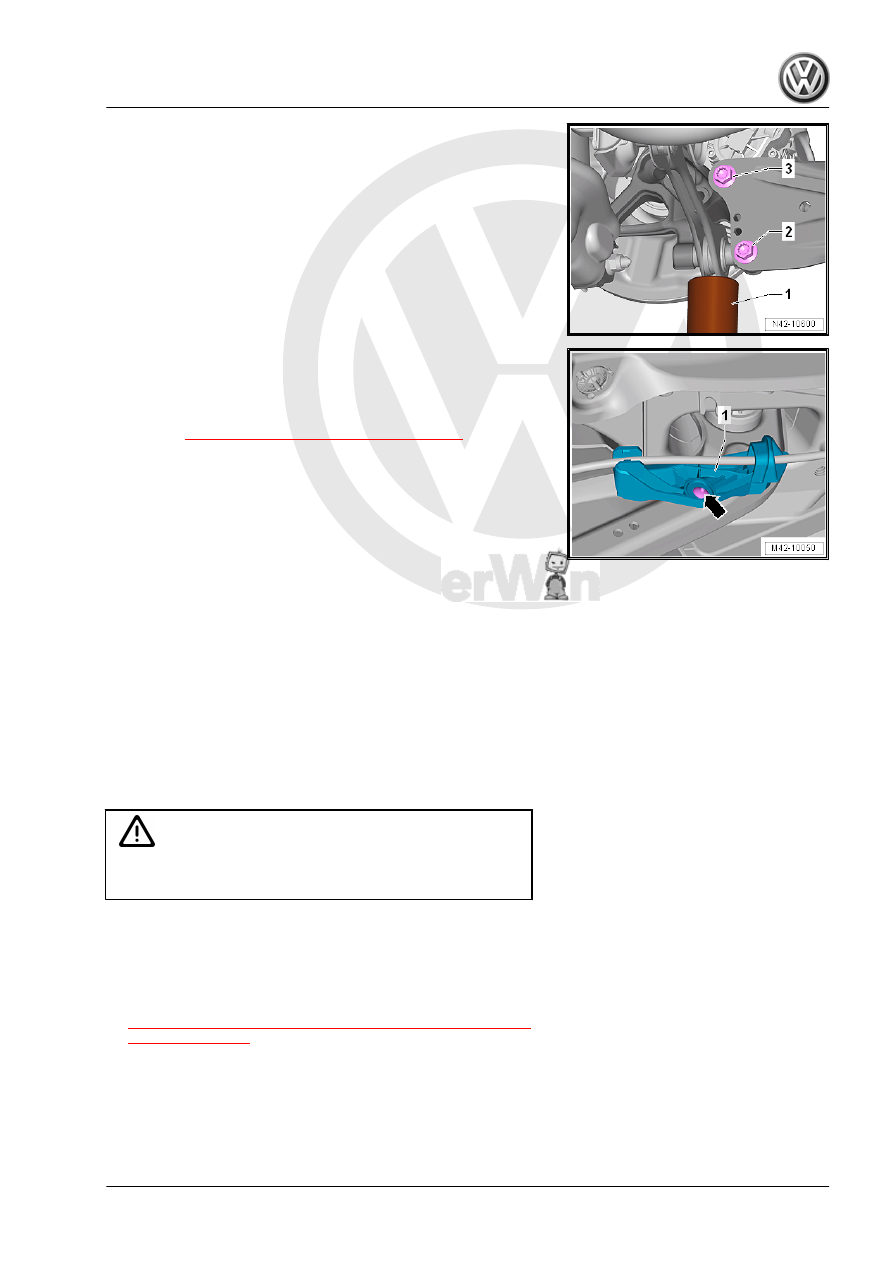

– Tighten the bolts -2 and 3-.

– Position the bracket -1- on the trailing arm.

– Insert a new rivet and push in a new inner pin -arrow-.

Tightening Specifications

♦ Refer to

⇒ “7.2 Overview - Trailing Arm”, page 213

After Installation, the Axle Alignment Must Be Checked on an

Alignment Rack.

7.7

Trailing Arm, Servicing

Special tools and workshop equipment required

♦ Bearing Installer - Wheel Bearing - 3345-

♦ Bearing Installer - Control Arm - 3346-

♦ Press Plate - VW402-

♦ Press Piece - Multiple Use - VW412-

♦ Press Piece - Trailing Arm Bushing - T10496-

♦ Torque Wrench 1332 40-200Nm - VAG1332-

♦ Engine and Gearbox Jack - VAS6931-

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Bolts - Trailing Arm to Wheel Bearing Housing

♦ Bolt - Trailing Arm to Mounting Bracket

– Remove trailing arm with mounting bracket. Refer to

⇒ “7.6 Trailing Arm with Mounting Bracket, Removing and In‐

.