Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 815

❑ Replace after removal

14 - Cover

3.2

Suspension Strut, Removing and Instal‐

ling

Special tools and workshop equipment required

♦ Torque Wrench 1332 40-200Nm - VAG1332-

♦ Spreader Tool - 3424-

♦ Engine and Gearbox Jack - VAS6931-

♦ Engine/Gearbox Jack Adapter - Wheel Hub Support - T10149-

♦ Drive Shaft Remover - T10520-

Removing

– Loosen drive axle bolt on the wheel hub. Refer to

⇒ “6.4 Drive Axle Threaded Connection, Loosening and Tight‐

.

Caution

The wheel bearing must not be under load when the drive axle

threaded connection on the wheel side is loose.

If the wheel bearings are under the load of the vehicle weight,

the wheel bearing will be damaged. This reduces the service

life of the wheel bearings.

The drive axle bolt may be loosened maximum 90° when the

vehicle is standing on its wheels.

Vehicles without a drive axle must not be moved, otherwise the

wheel bearing will be damaged. If a vehicle must be moved,

be sure to note the following:

♦ Install an outer joint in place of the drive axle.

♦ Tighten the outer joint to 120 Nm.

– Loosen the wheel bolts.

– Raise the vehicle.

– Remove the wheel.

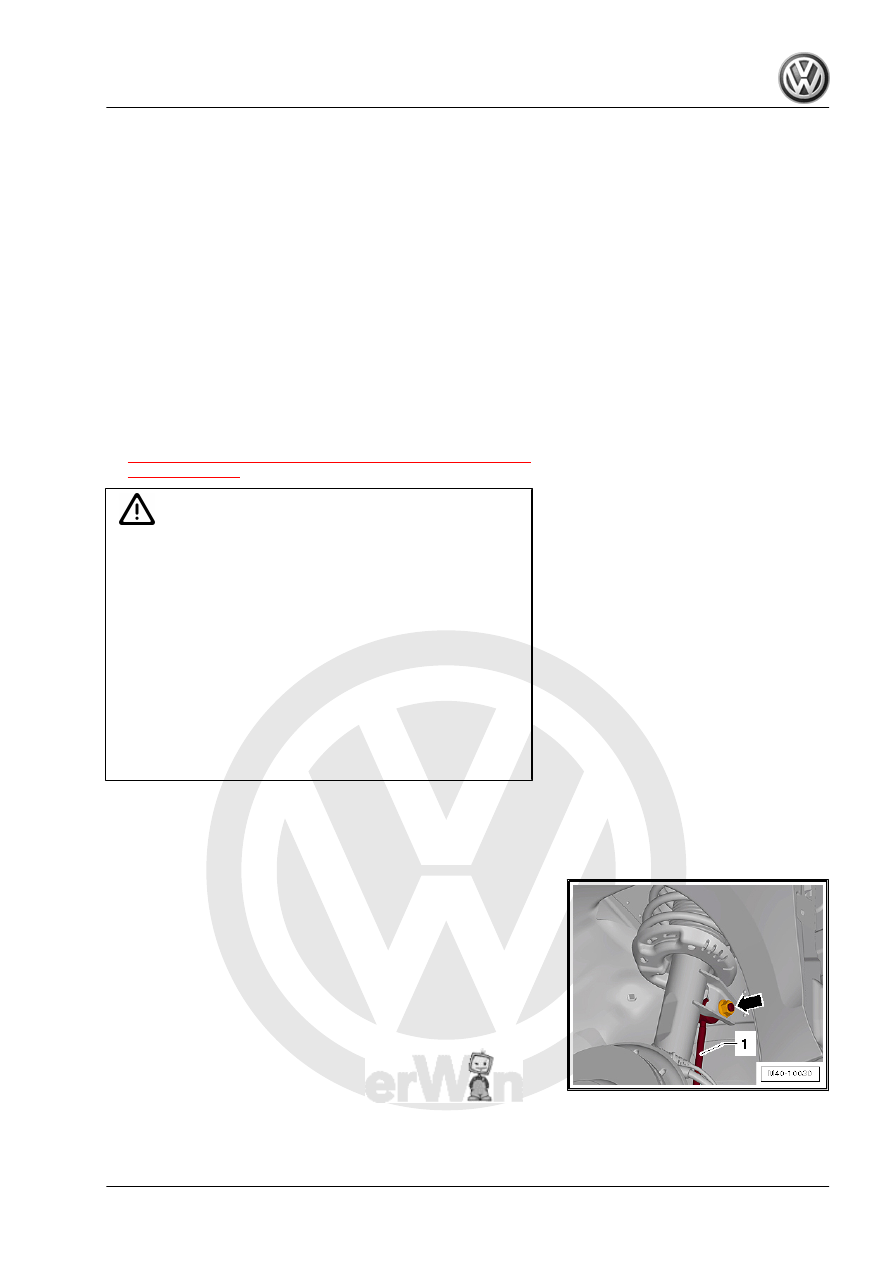

– Remove the nut -arrow- and the coupling rod -1- from the sus‐

pension strut.

– Disengage the wire for the ABS speed sensor from the sus‐

pension strut.