Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 806

Caution

All bolts at suspension parts with bonded rubber bushings must

always be tightened in curb weight position (unloaded condi‐

tion).

Bonded rubber bushings have a limited range of motion.

Axle components with bonded rubber bushings must be

brought into the position they will be in during driving before

tightening (curb weight position).

Otherwise, the bonded rubber bushing will be stressed result‐

ing in a shortened service life.

By raising the axle on one side using the Engine and Gearbox

Jack - VAS6931- and Engine/Gearbox Jack Adapter - Wheel Hub

Support - T10149- , this position can be simulated on the hoist.

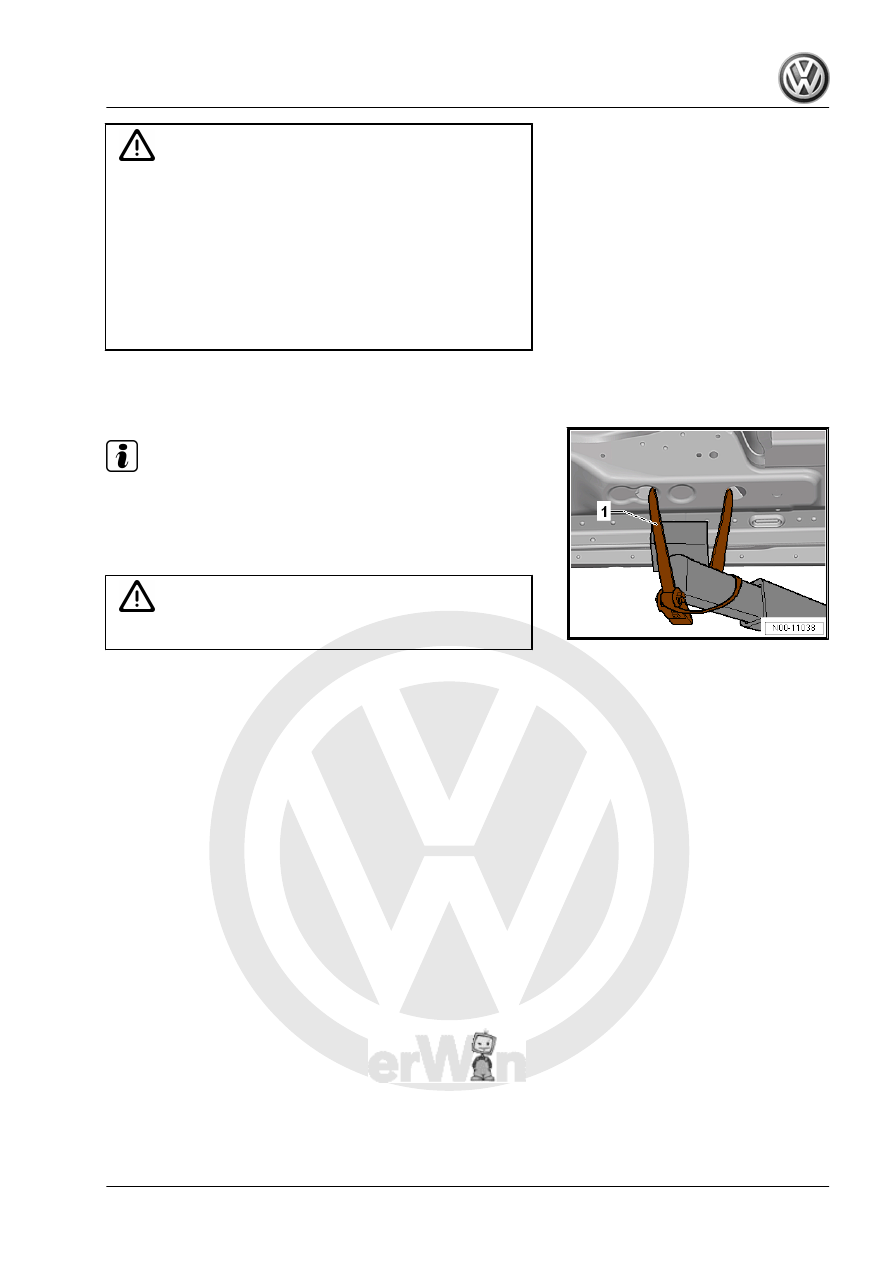

Note

Before lifting the axle on one side, the vehicle must be secured

on both sides to the lift arms of the lift using Tensioning Strap -

T10038- .

1 - Tensioning Strap - T10038-

WARNING

The vehicle could fall off the hoist if it is not secured.

– Turn the wheel hub until one of the holes for the wheel bolts

is on top.

– Install Engine/Gearbox Jack Adapter - Wheel Hub Support -

T10149- with wheel bolt.