Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 674

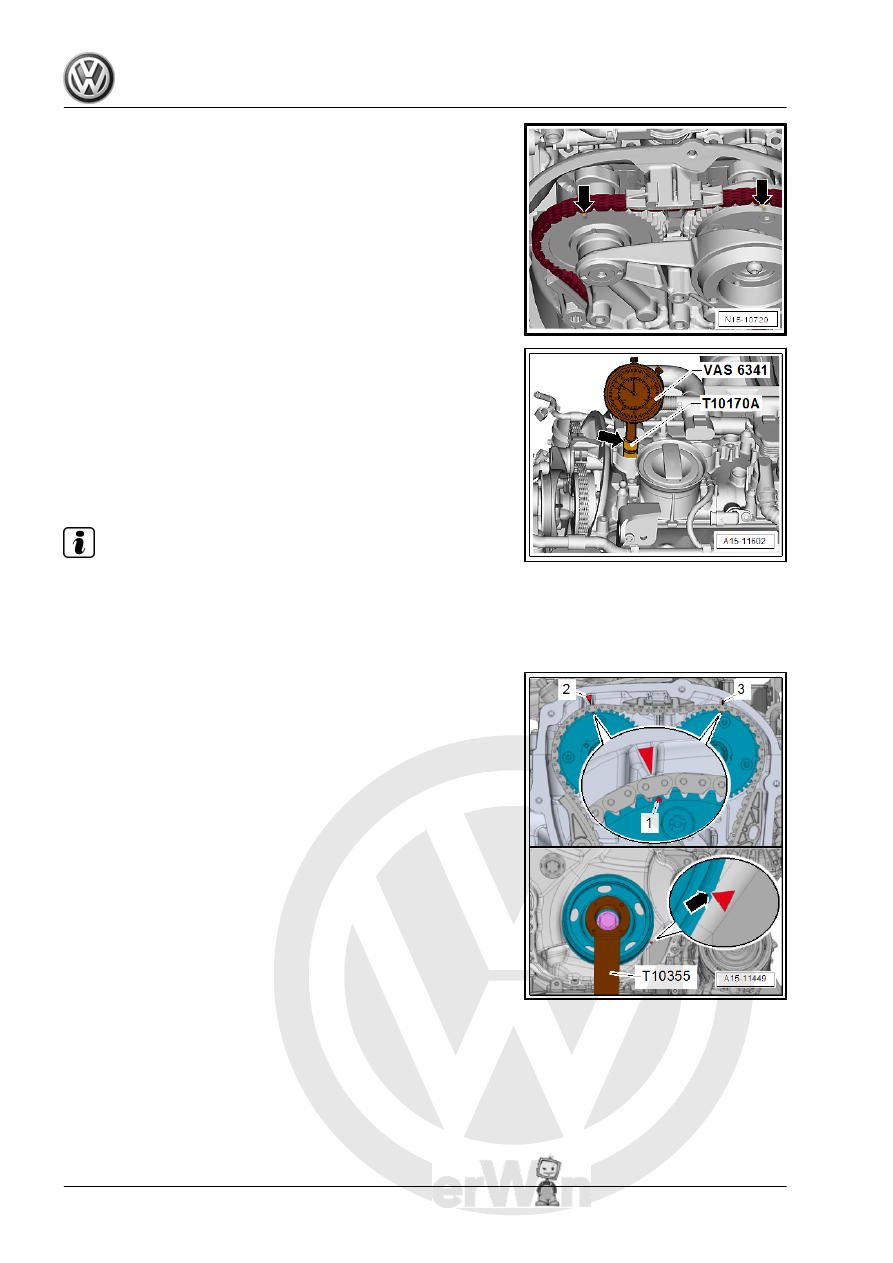

– Turn the crankshaft with the socket SW 24 on the vibration

damper in the direction of the engine rotation until the mark‐

ings -arrows- are almost on top.

– Remove the spark plug from cylinder 1.

– Install the Dial Gauge Adapter - T10170/A- all the way into the

spark plug thread.

– Insert the Dial Gauge - 0-10mm - VAS6341- using the Exten‐

sion - T10170A/1- until stop and secure with the locking nut

-arrow-.

– Turn the crankshaft slowly to maximum dial reading in the di‐

rection of the engine rotation. When the maximum dial reading

is reached (Bottom Dead Center (BDC) of the meter) position

the piston at »Top Dead Center (TDC)«.

Note

♦

Use a ratchet with a 24 mm socket to turn the vibration damper.

♦

If the crankshaft was turned past “TDC”, turn the crankshaft

two more turns in the direction of the engine rotation. Do not

turn the engine in the opposite direction of the engine rotation.

• The notch on the vibration damper must line up with the arrow

marking on the timing chain lower cover -arrow-.

• The markings -1- on the camshaft chain sprockets must be

opposite the markings -2 and 3- on the cylinder head.