Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 670

14 - Three Stage Chain Sprocket

❑ Crankshaft

❑ Installed position. Refer to

⇒ Fig. ““Three Stage Chain Sprocket - Installed Position”“ , page 116

Tightening Specification and Sequence for Bearing Bracket with

Steel Bolts

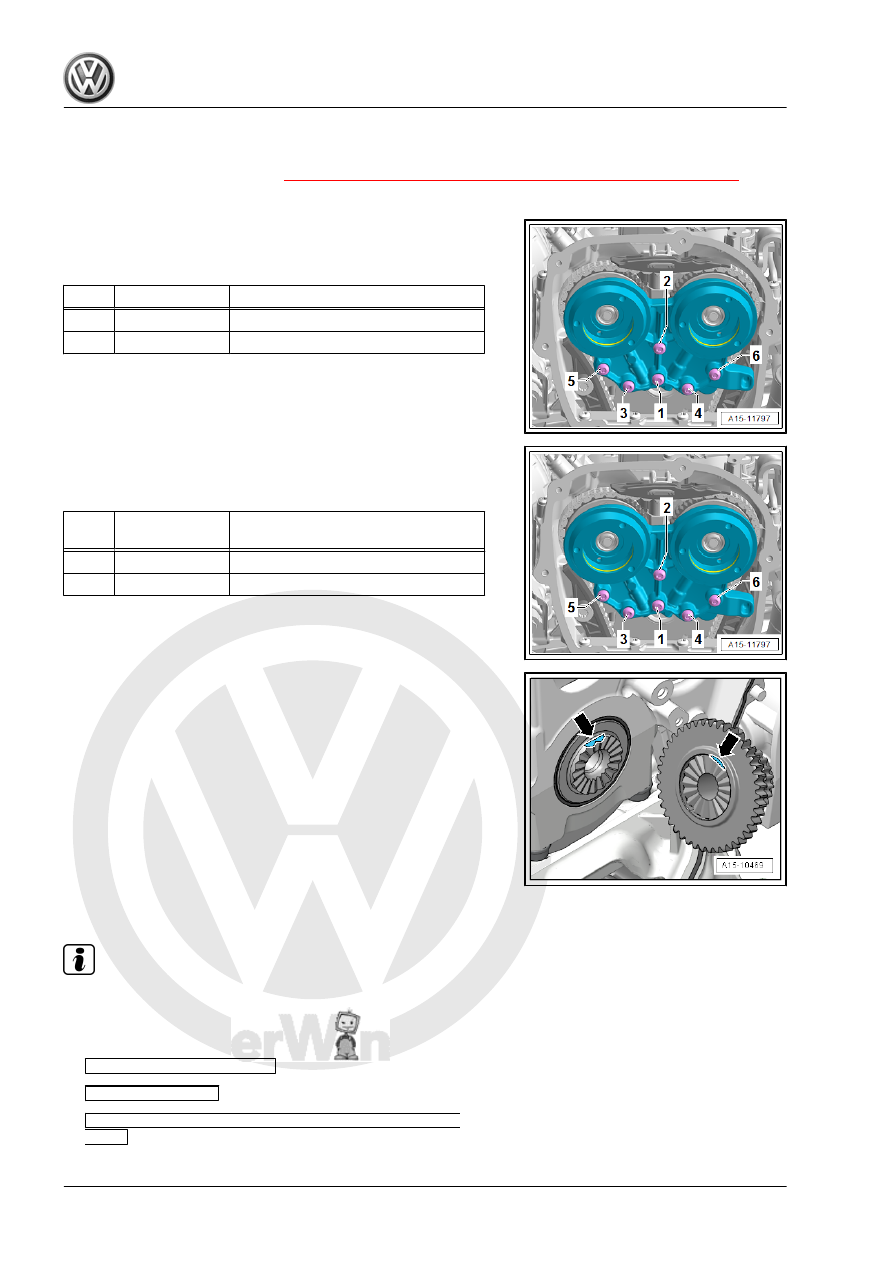

– Tighten the bolts in steps in the sequence shown:

Step

Bolts

Tightening Specifications

1.

-1-

3 Nm

2.

-1 to 6-

9 Nm

Tightening Specification and Sequence for Bearing Bracket with

Aluminum Bolts

– Tighten the bolts in steps in the sequence -1 to 6-:

Step

Bolts

Tightening Specification/Additional

Turn

1.

-1- through -6-

4 Nm

2.

-1- through -6-

180° additional turn

Three Stage Chain Sprocket - Installed Position

• Both surfaces must -arrows- must line up across from each

other.

3.2

Overview - Balance Shaft Drive Chain

Note

♦

After performing work on the chain drive the adaptation value

in the engine control module must be adapted. To do this turn

on the ignition and select the following menu items on the Ve‐

hicle Diagnostic Tester :

♦

01 - Engine electronics

♦

Guided functions

♦

01 - Adaptation after repair work on the chain

drive