Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 596

– Press the outer race/tapered roller bearing and the selected

shim (1.175 mm in the example) into the transmission housing

using the Press Piece - Multiple Use - VW510- .

– Install the transmission housing and tighten the bolts.

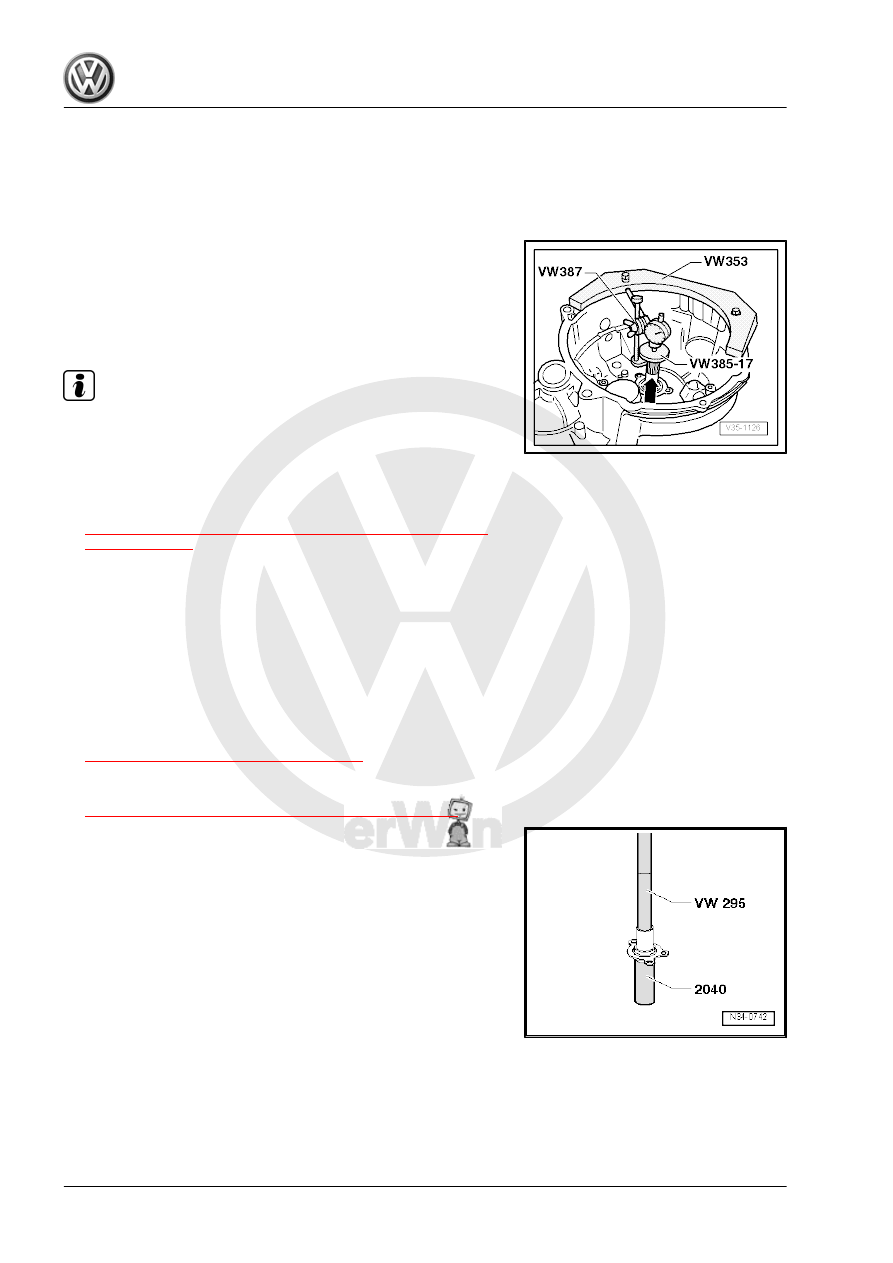

Checking Measurement

– Install the measuring device and the dial gauge.

– Turn the input shaft so that the tapered roller bearings settle.

– Press the input shaft in direction of -arrow-.

– Bearing play must be between a minimum 0.01 to maximum

0.09 mm.

Note

The adjustment is OK if it is not possible to measure the bearing

play and yet the input shaft still have a noticeable play and it easy

to turn.

Tightening Specifications

♦ Refer to

⇒ “5.4 Overview - Transmission Housing and Selector Mech‐

1.4

Input Shaft Seal, Replacing

Special tools and workshop equipment required

♦ Bearing/Bushing Installer - Multiple Use - VW295-

♦ Bearing/Bushing Installer - Multiple Use - VW295A-

♦ Press Piece - Multiple Use - VW454-

♦ Press Piece - Front Control Arm - 2040-

– Remove the transmission. Refer to

⇒ “2.1 Transmission, Removing”, page 67

– Remove the clutch release lever with the release bearing and

guide sleeve. Refer to

⇒ “1.16 Clutch Release Mechanism, Servicing”, page 35

.

– Drive seal out of guide sleeve.