Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 523

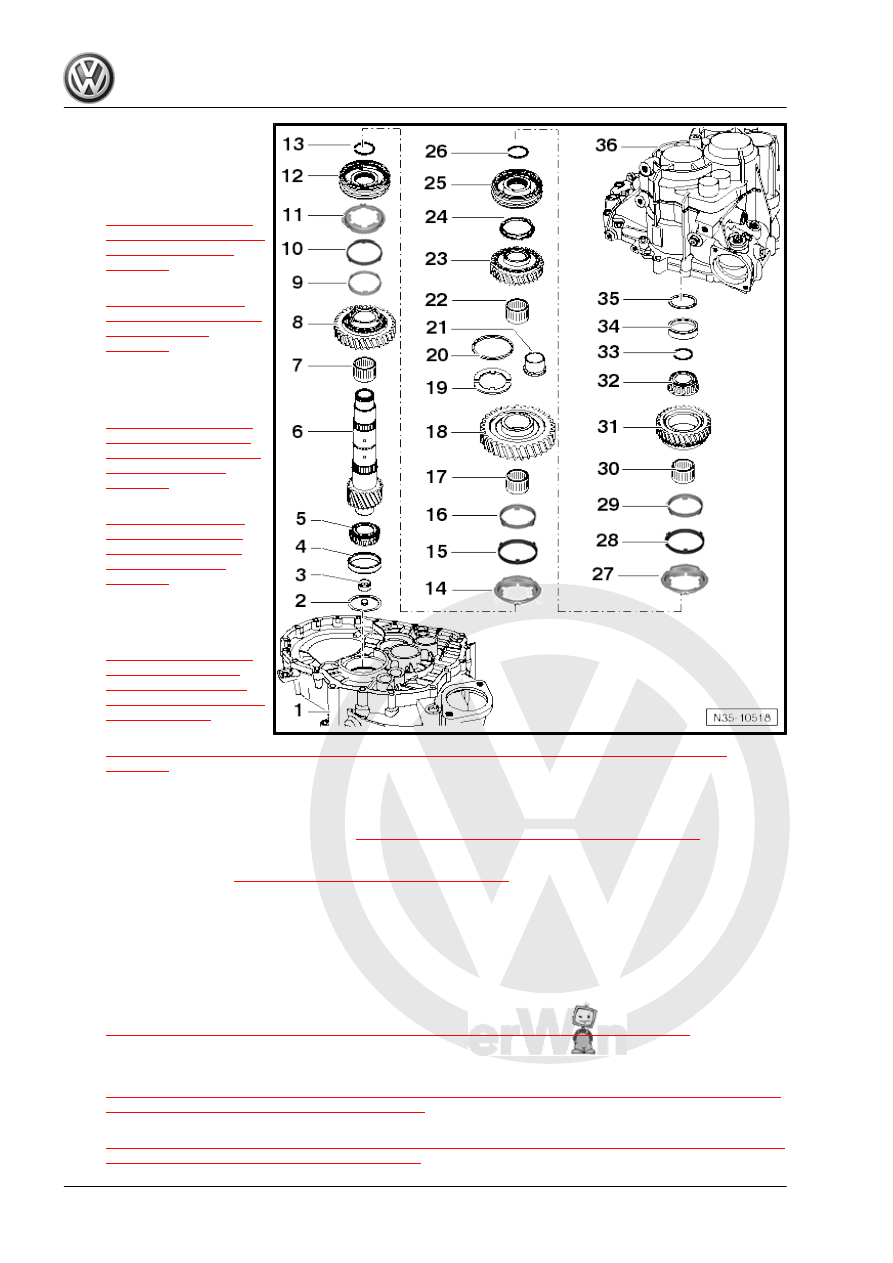

1 - Clutch Housing

2 - Oil Deflector Ring

3 - Dished Washer

❑ Removing. Refer to

❑ Installing. Refer to

4 - Outer Race/Tapered Roller

Bearing

❑ Removing. Refer to

❑ Installing. Refer to

5 - Inner Race / Tapered Roller

Bearing

❑ Removing. Refer to

❑ Installing. Refer to

⇒ Fig. ““Installing the Inner Race/Tapered Roller Bearing on the Side of the Clutch Housing”“ ,

6 - Output Shaft

❑ For 1st through 4th gear

❑ There are different versions. Refer to

⇒ Fig. ““Differentiation of Output Shafts”“ , page 168

❑ Allocate according to the transmission code letters. Refer to the Parts Catalog.

❑ Adjusting. Refer to

⇒ “2.3 Output Shaft, Adjusting”, page 187

7 - Needle Bearing

❑ For 2nd gear

8 - 2nd Gear Wheel

9 - 2nd Gear Inner Race

❑ Replace if there are wear grooves

❑ Installed position. Refer to

⇒ Fig. ““Installing 2nd Gear Outer Race, Inner Race and Synchronizer Ring”“ , page 177

10 - 2nd Gear Outer Race

❑ Check the inner friction surface for wear. Refer to

⇒ Fig. ““Checking the Inner Contact Surface for Wear on the 1st Gear Outer Ring, the 2nd Gear Outer

Ring, and the 3rd Gear Outer Ring ”“ , page 176

❑ Check the outer friction surface for wear. Refer to

⇒ Fig. ““Checking the Outer Contact Surface for Wear on the 1st Gear Outer Ring, the 2nd Gear Outer