Content .. 1221 1222 1223 1224 ..

Volkswagen Golf / Golf GTI / Jetta. Manual - part 1223

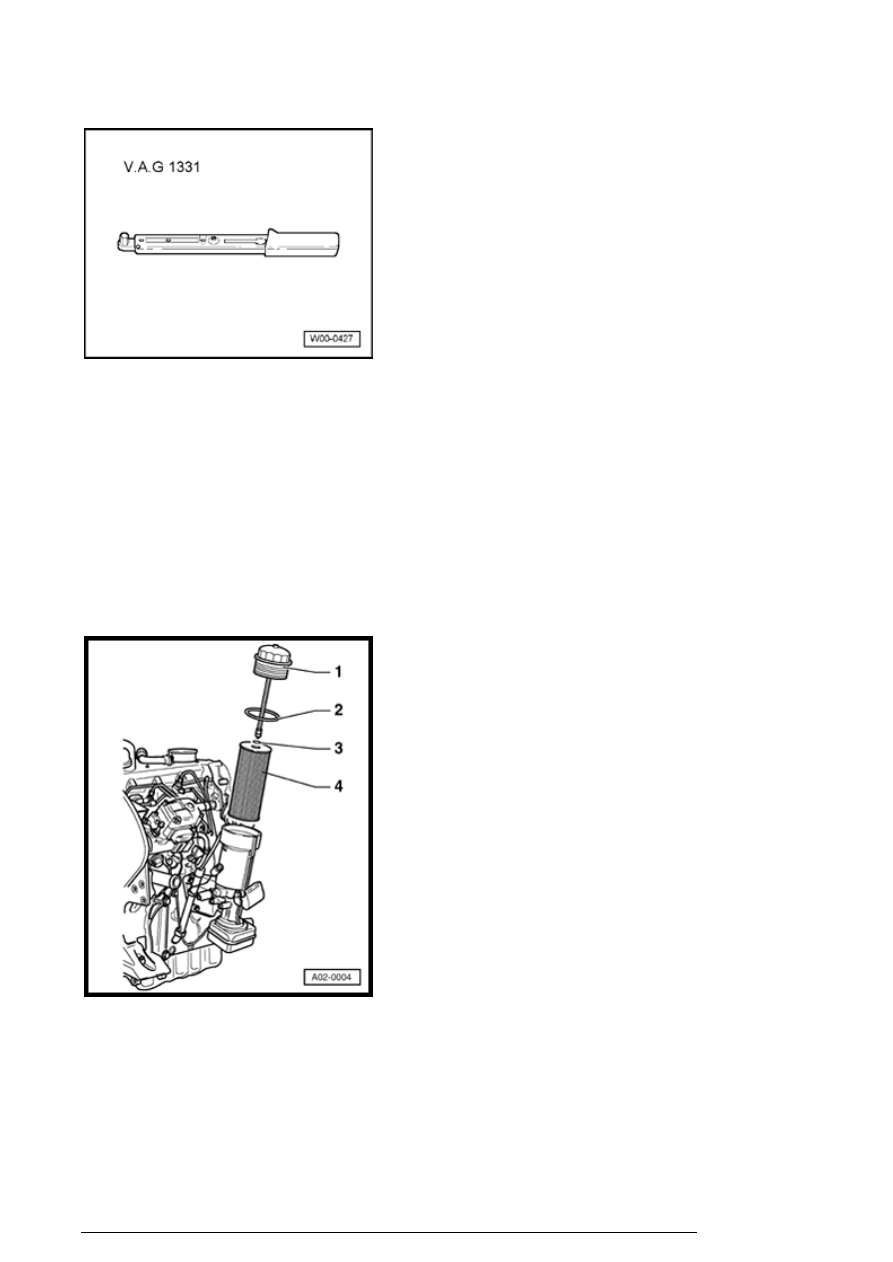

Torque wrench V.A.G 1331/ (5 - 50 Nm)

Oil filter wrench (commercially available)

or

Oil filter strap wrench

Perform following work sequence:

Engine code ALH

- Loosen cap - 1 - with Oil filter wrench VAS 3417 .

- Replace O-rings - 2 - and - 3 - along with oil filter - 4 - .

Note:

Observe waste disposal regulations!

Description of work (part 1 of 2)

13/2/2005