Toyota Automatic Transmission A340 Series. Repair Manual - part 34

AT4846

AT7910

AT4940

mm (in.)

23 (0.91)

12 (0.47)

20

(0.79)

AT1354

AT5066

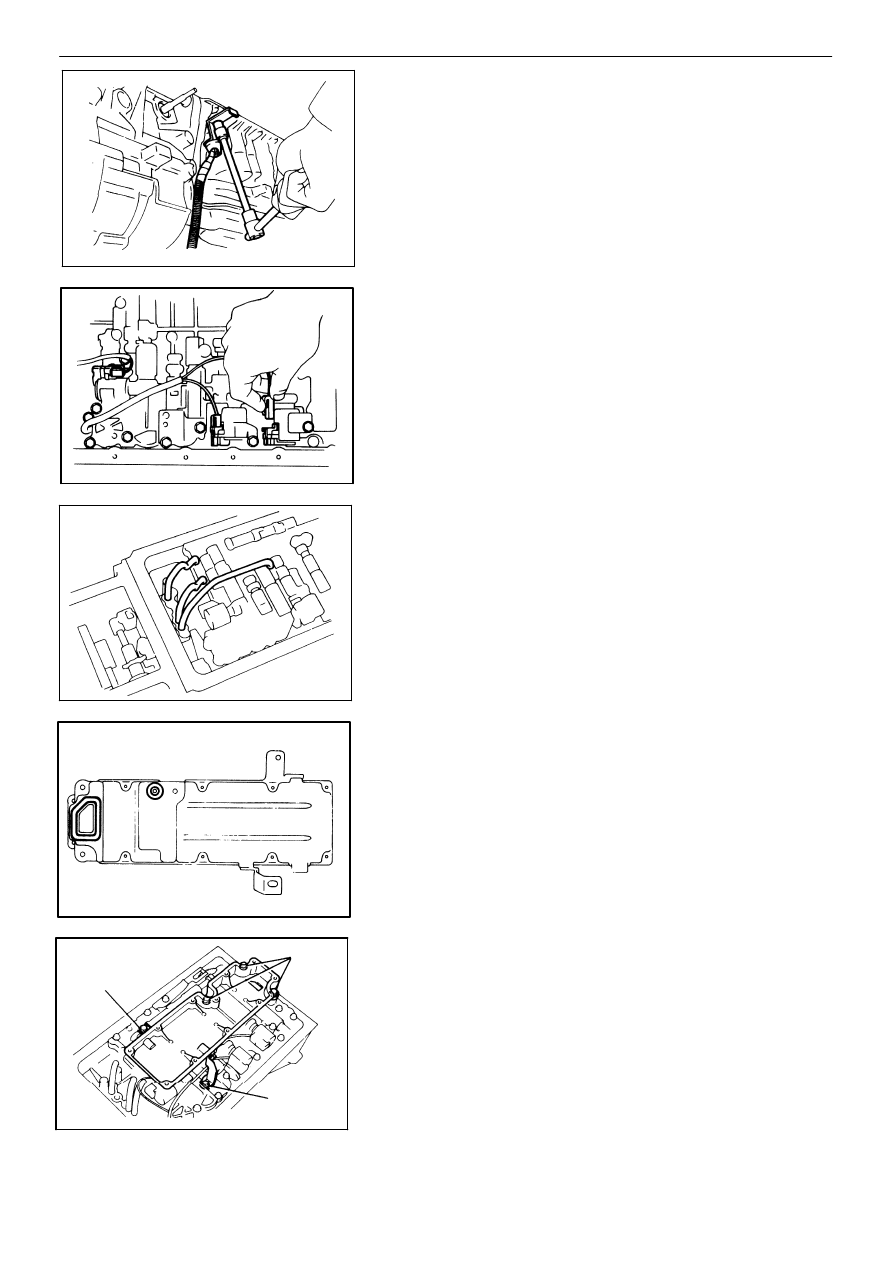

53. INSTALL TRANSMISSION SOLENOID WIRING

(a)

Coat a new O−ring with ATF and install it to the

grommet.

(b)

Insert the solenoid wiring to the case and install

the stopper plate.

(c)

Connect the connectors to No. 1, No. 2 and lock−

up solenoids.

54. INSTALL OIL TUBES

Using a plastic hammer, install the three tubes into

position shown in the figure.

NOTICE: Be careful not to bend or damage the tubes.

55. INSTALL OIL STRAINER AND GASKETS

(a)

Install two new gaskets to the oil strainer case.

(b)

Install the oil strainer case and torque the five bolts.

Torque: 100 kg−cm (7 ft−lb, 10 N−m)

HINT: Each bolt length (mm, in.) is indicated in the figure.

−

AUTOMATIC TRANSMISSION (A340H)

Installation of Component Parts

AT−261