Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 238

IG–4

1GR-FE IGNITION – IGNITION SYSTEM

IG

ON-VEHICLE INSPECTION

1.

CHECK IGNITION COIL ASSEMBLY AND PERFORM

SPARK TEST

(a) Check for DTCs.

NOTICE:

If any DTC is present, perform troubleshooting

in accordance with a procedure for that DTC.

(b) Check that sparks occur.

(1) Remove the ignition coils.

(2) Using a 16 mm plug wrench, remove the spark

plugs.

(3) Install the spark plugs onto the ignition coils,

and connect the ignition coil connectors.

(4) Disconnect the 6 injector connectors.

(5) Ground the spark plugs.

(6) Check that sparks occur at each spark plug

while the engine is being cranked.

NOTICE:

•

Be sure to ground the spark plugs when

checking.

•

Replace any ignition coils that have been

subjected to any physical impact.

•

Do not crank the engine for more than 2

seconds.

If sparks do not occur, perform the following

test:

(c) Spark test flow chart.

(1) Check that the wire harness side connector of

ignition coil with igniter is securely connected.

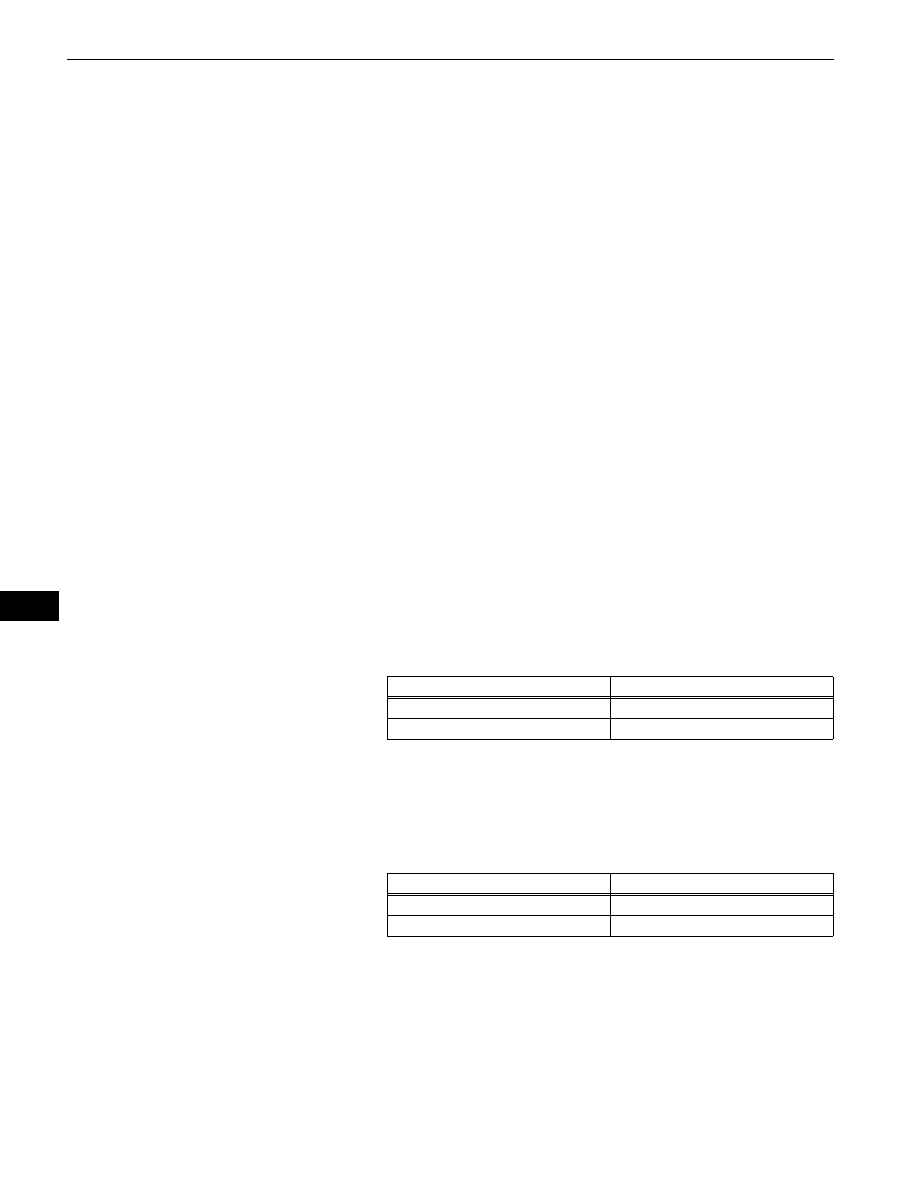

Result

(2) Perform the spark test on each ignition coil with

igniter.

1.Replace the ignition coil with igniter with a

functioning one.

2.Perform the spark test again.

Result

(3) Check that the power is supplied to the ignition

coil.

1.Turn the ignition switch ON.

2.Check that the positive (+) battery voltage is

applied to the positive (+) terminal of the

ignition coil.

Result

Proceed to

NG

Connect securely.

OK

Go to next step.

Result

Proceed to

OK

Replace ignition coil with igniter.

NG

Go to next step.