Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 85

1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–295

ES

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

FAIL-SAFE

When this DTC, as well as other DTCs relating to ETCS (Electronic Throttle Control System)

malfunctions, is set, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to

the throttle actuator off, and the throttle valve is returned to a 6

° throttle angle by the return spring. The

ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition

timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a

minimal speed. If the accelerator pedal is depressed firmly and gently, the vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned OFF.

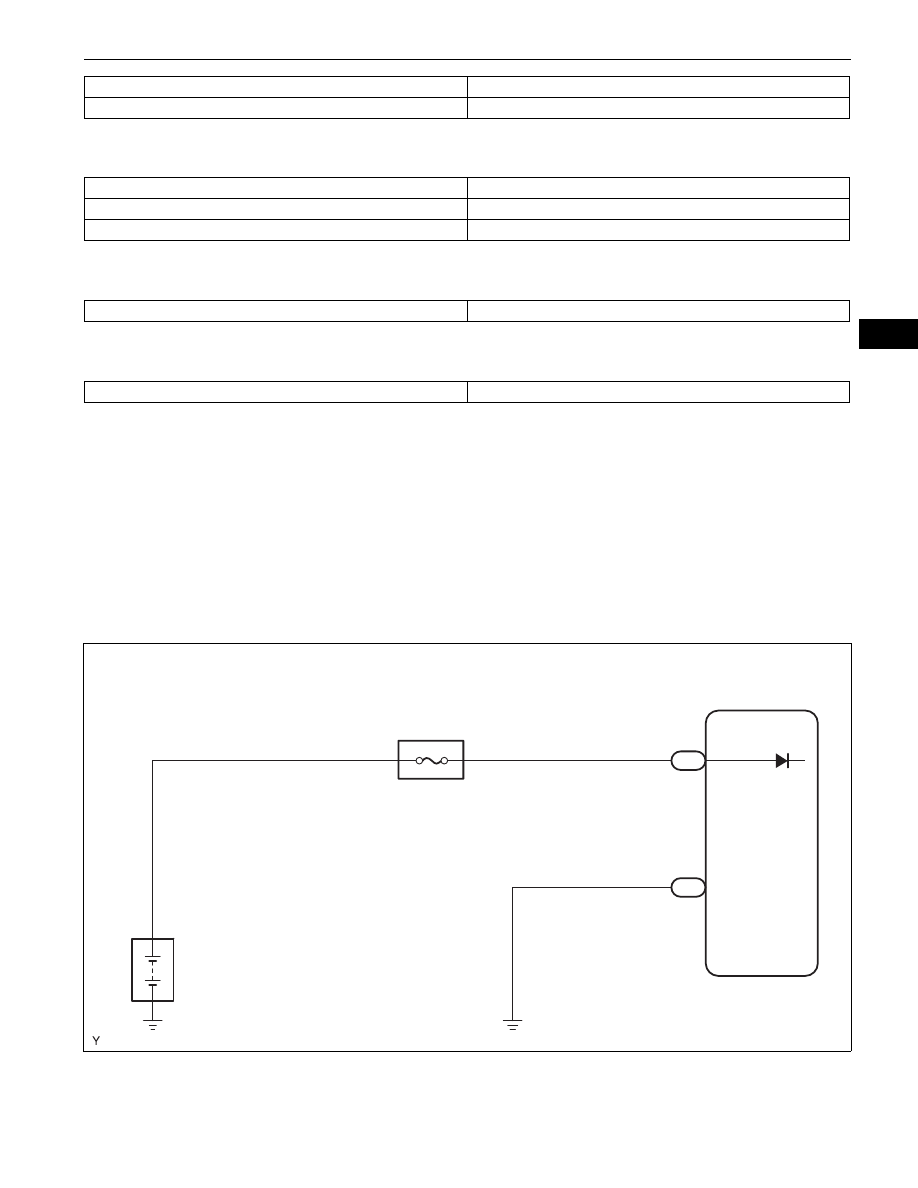

WIRING DIAGRAM

MIL Operation

Immediate

Sequence of Operation

None

Monitor runs whenever following DTCs not present

None

Electronic throttle actuator power

ON

Battery voltage

8 V or more

Electronic throttle actuator power supply voltage (+BM)

Less than 4 V

Throttle actuator power supply voltage

11 to 14 V

ETCS

Battery

ECM

+BM

ME01

2

1

7

E47

3

B2

A133422E02