Suzuki Grand Vitara JB627. Manual - part 412

10A-14 Cruise Control System:

DTC Troubleshooting

NOTE

Before this trouble shooting, read and observe “Precautions for DTC Troubleshooting in Section 1A”.

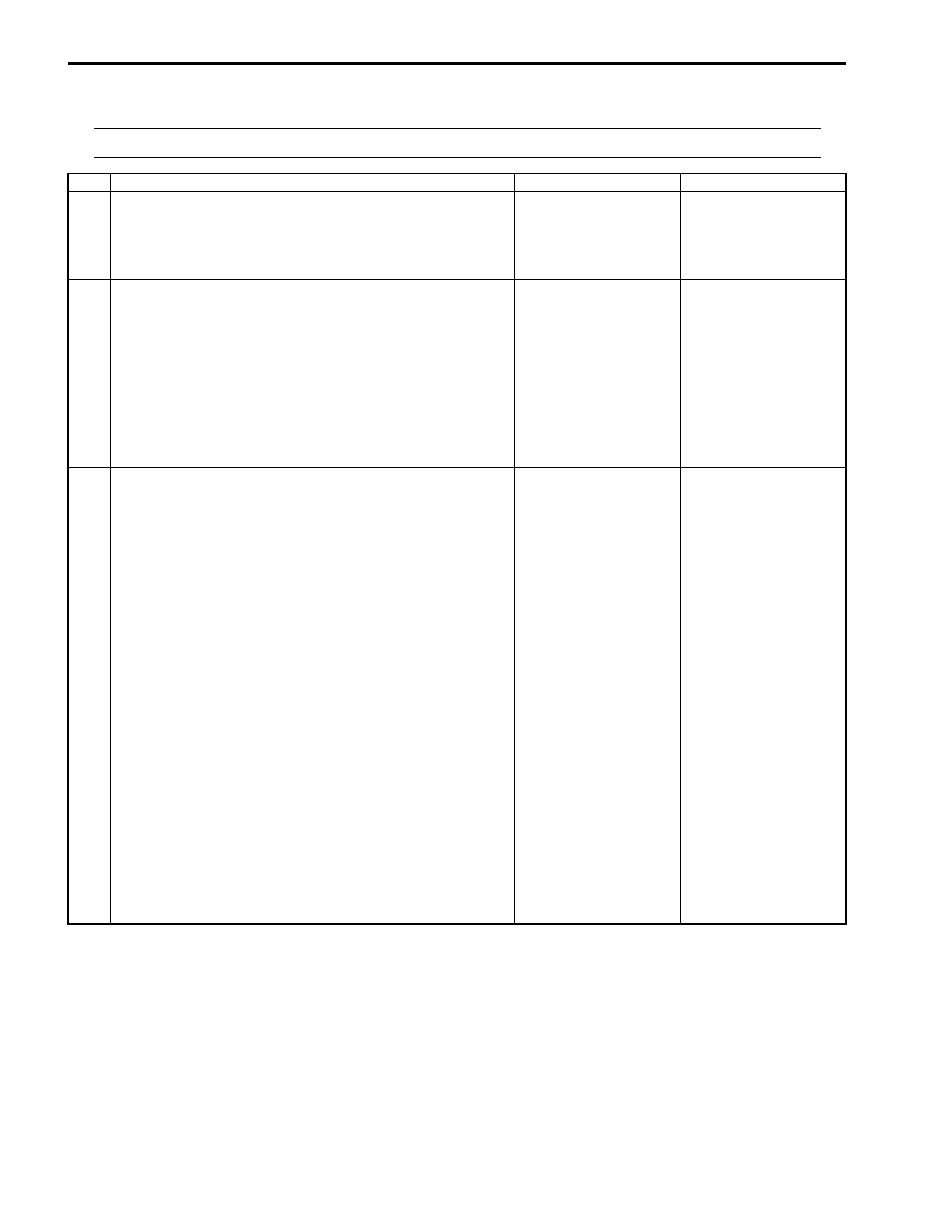

Step

Action

Yes

No

1

Brake light switch check

1) Check brake light switch referring to “Brake Light Switch

Is it in good condition?

Go to Step 2.

Replace brake light

switch.

2

Brake light switch power circuit check

1) Disconnect connector from brake light switch connector

with ignition switch turned OFF.

2) Check for proper connection to switch connector.

3) If connection are OK, measure voltage between each

“BLU/BLK” wire terminal and “GRN” wire terminal of

brake light switch connector and vehicle body ground

with ignition switch tuned ON.

Is each measured voltage 10 – 14 V?

Go to Step 3.

Check related fuse and

repair defective circuit.

3

Brake light switch signal circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of each switch circuit

terminal to ECM connector.

3) If connections are OK, check brake light switch circuit for

the following.

• Resistance of each “YEL/GRN” wire terminal and

“GRN/WHT” wire terminal of brake light switch

between brake light switch connector and ECM

connector is less than 1

Ω (continuity check)

• Resistance between “YEL/GRN” wire terminal and

“GRN/WHT” wire terminal of brake light switch

connector are infinity (no continuity check)

• Resistance between each “YEL/GRN” wire terminal

and “GRN/WHT” wire terminal of brake light switch

connector and vehicle body ground is infinity (ground

short check)

• Voltage of between each “YEL/GRN” wire terminal

and “GRN/WHT” wire terminal of brake light switch

connector and vehicle body ground is 0 V with ignition

switch tuned ON (power short check)

Is it in good condition?

Substitute a known-

good ECM and recheck.

Repair or replace

defective wire.