Suzuki Grand Vitara JB627. Manual - part 250

5B-23 Manual Transmission/Transaxle:

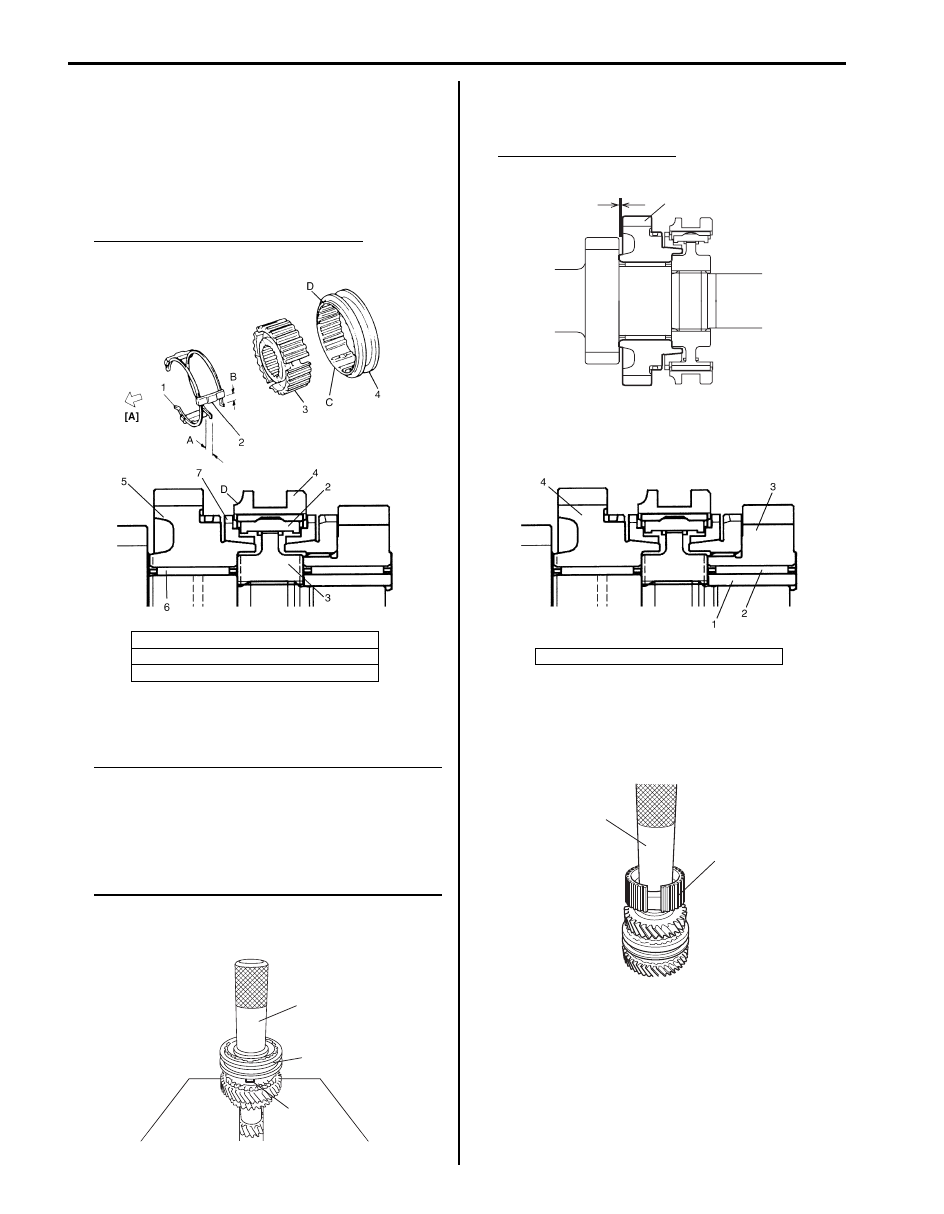

5) Assemble synchronizer sleeve (4) and hub (3) as

follows.

a) Fit high speed synchronizer sleeve to hub in

specified direction as shown in figure.

b) Insert 3 keys (2) to hub.

c) Set springs (1) at specified position as shown in

figure.

Synchronizer key installation position

: A = B

6) Drive in high speed synchronizer assembly (1) using

special tool and hammer.

NOTE

• While press-fitting sleeve & hub, make

sure that synchronizer ring key slots (2)

are aligned with keys in sleeve & hub

assembly.

• Check free rotation of 4th gear after press

fitting sleeve & hub assembly.

Special tool

(A): 09913–84510

7) Check 4th gear (1) thrust clearance by using

thickness gauge. If clearance is out of specification,

repress-fit or replace defective part.

4th gear thrust clearance

“a”: 0.10 – 0.25 mm (0.004 – 0.010 in.)

8) Apply oil to high speed gear needle bearing, and

then install 3rd gear bush (1), high speed gear

needle bearing (2) and 3rd gear (3).

9) Press-fit 5th speed synchronizer hub (1) using

special tool and hammer.

Special tool

(A): 09913–84510

[A]: 4th gear side

C: Key way

D: Projecting end

I5JB0A520060-01

(A)

1

2

I5JB0A520061-01

4. 4th gear

“a”

1

I5JB0A520062-01

I5JB0A520063-01

(A)

1

I5JB0A520064-01