Suzuki Grand Vitara JB627. Manual - part 225

5A-84 Automatic Transmission/Transaxle:

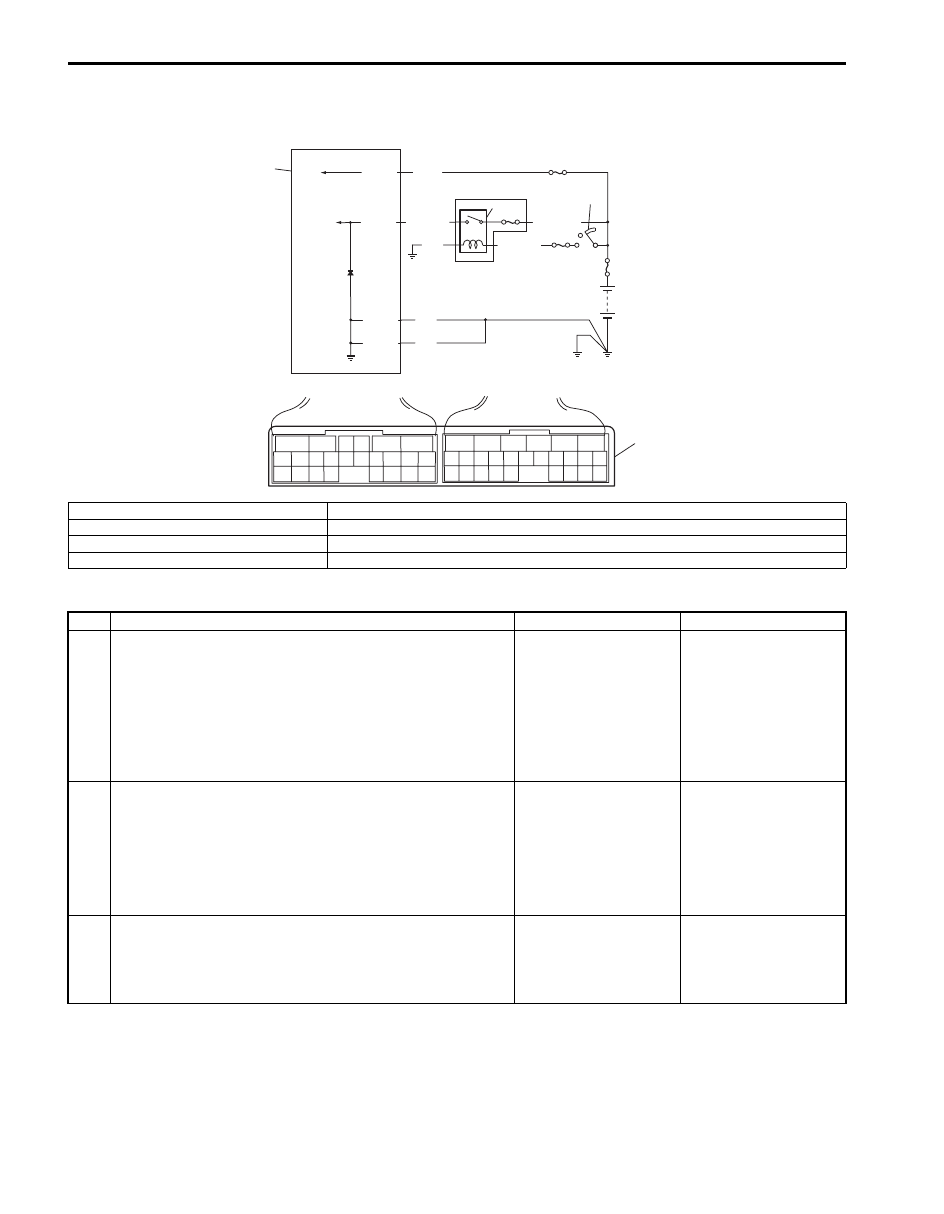

TCM Power and Ground Circuit Check

S6JB0B5104050

Wiring Diagram

Troubleshooting

BLK

BLK

BLK

E92-1

E92-23

E92-6

BLK/WHT

BLK/WHT

WHT/GRN

E92-24

WHT

1

2

3

4

7

6

5

6

5

16 15 14 13 12 11

4 3

24 23

21

22

10 9

8

7

2

1

19

20

18 17

E92

17 16

26 25

15 14

6

5

3

4

2

13 12

23 22

24

11 10 9

21 20 19

8 7

18

1

E93

8

I5JB0A510152-01

1. TCM

5. Ignition switch

2. A/T relay

6. “IG COIL” fuse

3. “AT” fuse

7. Power integration No.2 in main fuse box

4. “DOME” fuse

8. Terminal arrangement of TCM connector (viewed from harness side)

Step

Action

Yes

No

1

Check TCM back-up power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “E92-24”

terminal.

3) If OK, check voltage at terminal “E92-24” of

disconnected TCM connector.

Is it 10 – 14 V?

Go to Step 2.

“WHT” circuit open or

shorted to ground.

2

Check TCM power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “E92-6” terminal.

3) If OK, turn ignition switch ON and check voltage at

terminal “E92-6” of disconnected TCM connector.

Is it 10 – 14 V?

Go to Step 4.

Go to Step 3.

3

Check A/T relay operation

1) Check A/T relay operation referring to “A/T Relay

Is check result satisfactory?

“BLK/WHT”, “WHT/

GRN”, or “BLK” circuit

for power supply open.

Replace A/T relay

included in power

integration No.2 in main

fuse box.