Suzuki Grand Vitara JB627. Manual - part 172

4A-7 Brake Control System and Diagnosis:

Repair Instructions

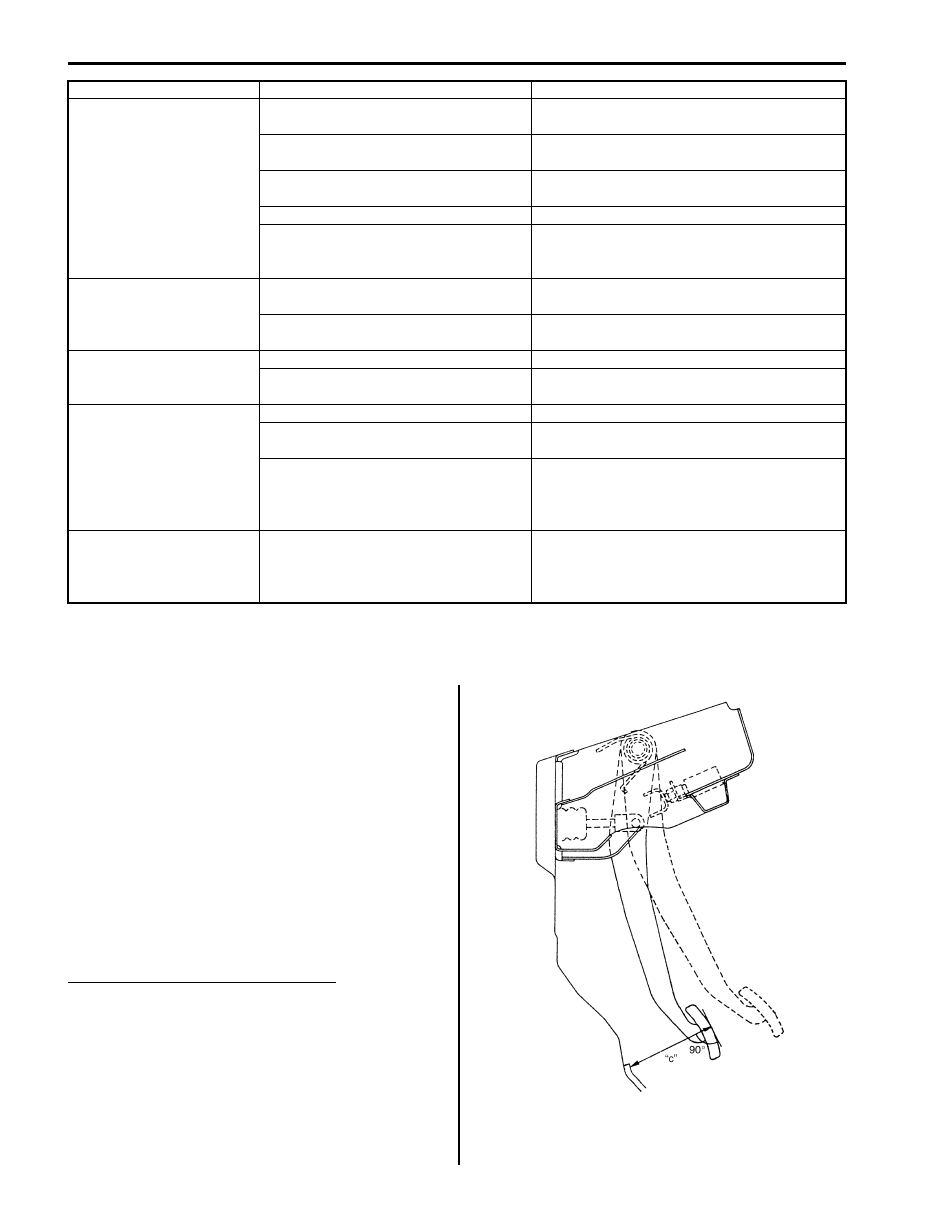

Excessive Pedal Travel Check

S6JB0B4106001

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 30

kg (66 lbs) load, measure pedal to carpet clearance

“c”.

If clearance “c” is less than specification, the most

possible cause is either rear brake shoes are worn

out beyond limit or air is in lines.

Should clearance “c” remain less than specification

even after replacement of brake shoes and bleeding

of system, other possible but infrequent cause is

malfunction of rear brake shoe adjusters or booster

push rod length out of adjustment.

Brake pedal arm to wall clearance “c”

When pedal depressed at 300 N (30 kg, 66 lbs): Over

70 mm (2.75 in.)

Brake warning light turns

ON after engine start

Parking brake applied

Release parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluid

Investigate leaky point, correct it and add

brake fluid.

Brake fluid leaking from brake line

Investigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faulty

Repair circuit.

Malfunctioning EBD system

Check system referring to “ABS Check in

Section 4E” or “ESP

Brake warning light turns

on when brake is applied

Brake fluid leaking from brake line

Investigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluid

Investigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is applied

Bulb burnt out

Replace bulb.

Brake warning light circuit faulty

Repair circuit.

ABS warning light does

not turn ON for 2 – 3 sec.

after ignition switch has

turned ON

Bulb burnt out

Replace bulb.

ABS warning light circuit open (including

check relay)

Repair or replace.

Malfunctioning ABS (ESP

®)

Check system referring to “ABS Warning Light

Does Not Come ON at Ignition Switch ON in

Section 4E” or “ESP

Come ON at Ignition Switch ON in Section 4F”.

ABS warning light

remains ON after ignition

switch has turned ON for

2 – 3 sec.

Malfunctioning ABS (ESP

®)

Check system referring to “ABS Warning Light

Comes ON Steady in Section 4E” or “ESP

Warning Light Comes ON Steady in Section

4F”.

Condition

Possible cause

Correction / Reference Item

IYSQ01410009-01