Subaru Legacy IV (2008 year). Manual - part 694

4AT-124

AT Main Case

AUTOMATIC TRANSMISSION

5. ONE-WAY CLUTCH OUTER RACE

1) Install the needle bearing, and then secure with

the snap ring.

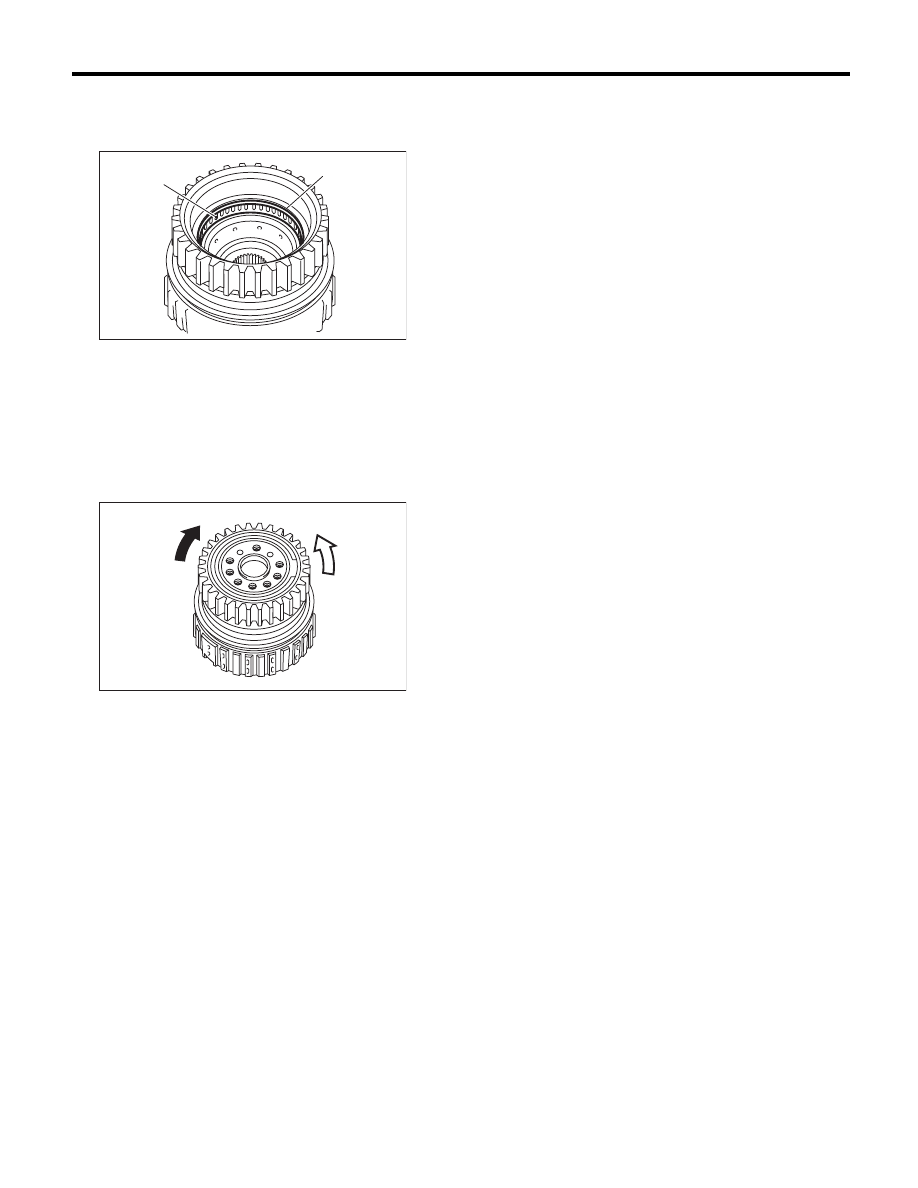

2) Install the one-way clutch and one-way clutch in-

ner race, then secure with the snap ring.

3) Set the inner race. Make sure that the clutch

locks in the clockwise direction and rotates freely in

the counterclockwise direction.

E: INSPECTION

1. HIGH CLUTCH AND REVERSE CLUTCH

Check the following items.

• Drive plate facing for wear or damage

• Driven plate for discoloration (burned color)

• Snap ring wear and spring retainer deformation

• Wear and damage of the lip seal and D-ring

• Piston and piston check ball operation

• Adjust the total end play. <Ref. to 4AT-88, AD-

JUSTMENT, Oil Pump Housing.>

2. PLANETARY GEAR AND LOW CLUTCH

Check the following items.

• Drive plate facing for wear or damage

• Driven plate for discoloration (burned color)

• Snap ring wear and spring retainer deformation

• Wear and damage of the lip seal and D-ring

• Measure the total end play and adjust it to be

within specifications. <Ref. to 4AT-88, ADJUST-

MENT, Oil Pump Housing.>

3. 2-4 BRAKE

Check the following items.

• Drive plate facing for wear or damage

• Driven plate for discoloration (burned color)

• Snap ring wear, leaf spring setting and break-

age, and spring retainer deformation

• Wear and damage of the lip seal and D-ring

• Measure the total end play and adjust it to be

within specifications. <Ref. to 4AT-88, ADJUST-

MENT, Oil Pump Housing.>

4. ONE-WAY CLUTCH

• Check that the snap ring is not damaged and the

seal ring is not deformed.

• Measure the total end play and adjust it to be

within specifications. <Ref. to 4AT-88, ADJUST-

MENT, Oil Pump Housing.>

5. LOW & REVERSE BRAKE

Check the following items.

• Drive plate facing for wear or damage

• Driven plate for discoloration (burned color)

• Snap ring wear, leaf spring setting and break-

age, and spring retainer deformation

• Lip seal wear and damage

(A) Needle bearing

(B) Snap ring

(A) Lock

(B) Free

AT-00268

(B)

(A)

AT-00282

(B)

(A)