Subaru Legacy IV (2008 year). Manual - part 676

4AT-52

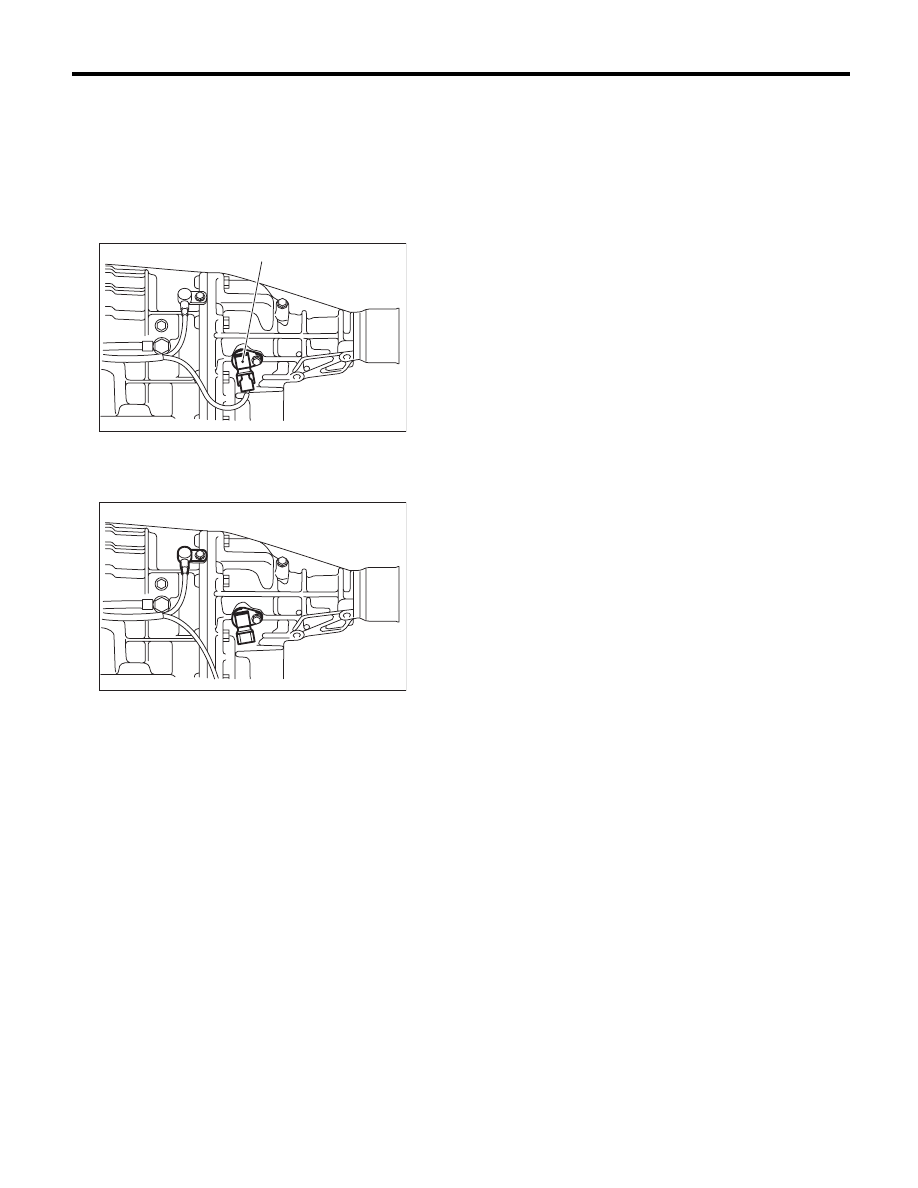

Rear Vehicle Speed Sensor

AUTOMATIC TRANSMISSION

15.Rear Vehicle Speed Sensor

A: REMOVAL

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Lift up the vehicle.

4) Disconnect the connector from the rear vehicle

speed sensor.

5) Remove the rear vehicle speed sensor.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Replace the O-ring with a new part.

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

(A) Rear vehicle speed sensor

AT-02207

(A)

AT-01341