Subaru Legacy IV (2008 year). Manual - part 582

EN(H6DO)(diag)-301

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

25

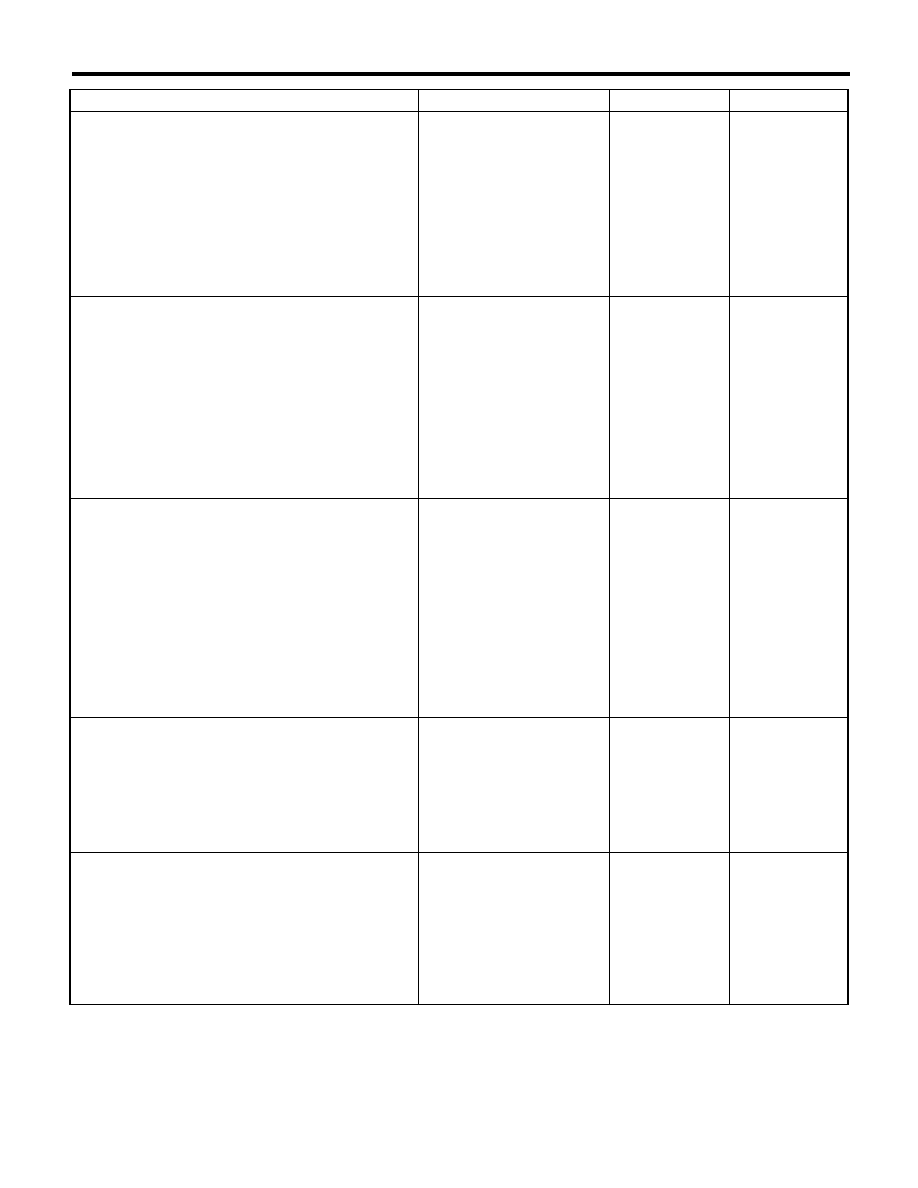

CHECK SHORT CIRCUIT INSIDE THE ECM.

1) Connect the connector to ECM.

2) Measure the resistance between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 6 — Engine ground:

(E57) No. 4 — Engine ground:

Is the resistance 1 M

: or

more?

Go to step 26.

Repair the short

circuit to ground in

harness between

ECM and elec-

tronic throttle con-

trol connector.

Replace the ECM if

defective. <Ref. to

FU(H6DO)-38,

Engine Control

Module (ECM).>

26

CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Disconnect the connectors from ECM.

2) Measure the resistance of harness between

ECM and electronic throttle control connector.

Connector & terminal

(B134) No. 18 — (E57) No. 6:

(B134) No. 28 — (E57) No. 4:

(B134) No. 29 — (E57) No. 3:

Is the resistance less than 1

:? Go to step 27.

Repair the harness

and connector.

NOTE:

In this case, repair

the following item:

• Open circuit in

harness between

ECM and electron-

ic throttle control

connector

• Poor contact of

coupling connector

27

CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Connect the connector to ECM.

2) Measure the resistance between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 3 — Engine ground:

Is the resistance less than 5

:? Go to step 28.

Repair the harness

and connector.

NOTE:

In this case, repair

the following item:

• Open circuit of

harness between

ECM and engine

ground

• Poor contact in

ECM connector

• Poor contact of

coupling connector

28

CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Turn the ignition switch to ON.

2) Measure the voltage between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 6 (+) — Engine ground (–):

(E57) No. 4 (+) — Engine ground (–):

Is the voltage 4.85 V or more?

Repair the short

circuit to power in

the harness

between ECM and

electronic throttle

control connector.

Go to step 29.

29

CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance between ECM con-

nectors.

Connector & terminal

(B134) No. 19 — (B134) No. 18:

(B134) No. 19 — (B134) No. 28:

Is the resistance 1 M

: or

more?

Go to step 30.

Repair the short

circuit to power in

the harness

between ECM and

electronic throttle

control connector.

Step

Check

Yes

No