Subaru Legacy IV (2008 year). Manual - part 518

EN(H6DO)(diag)-45

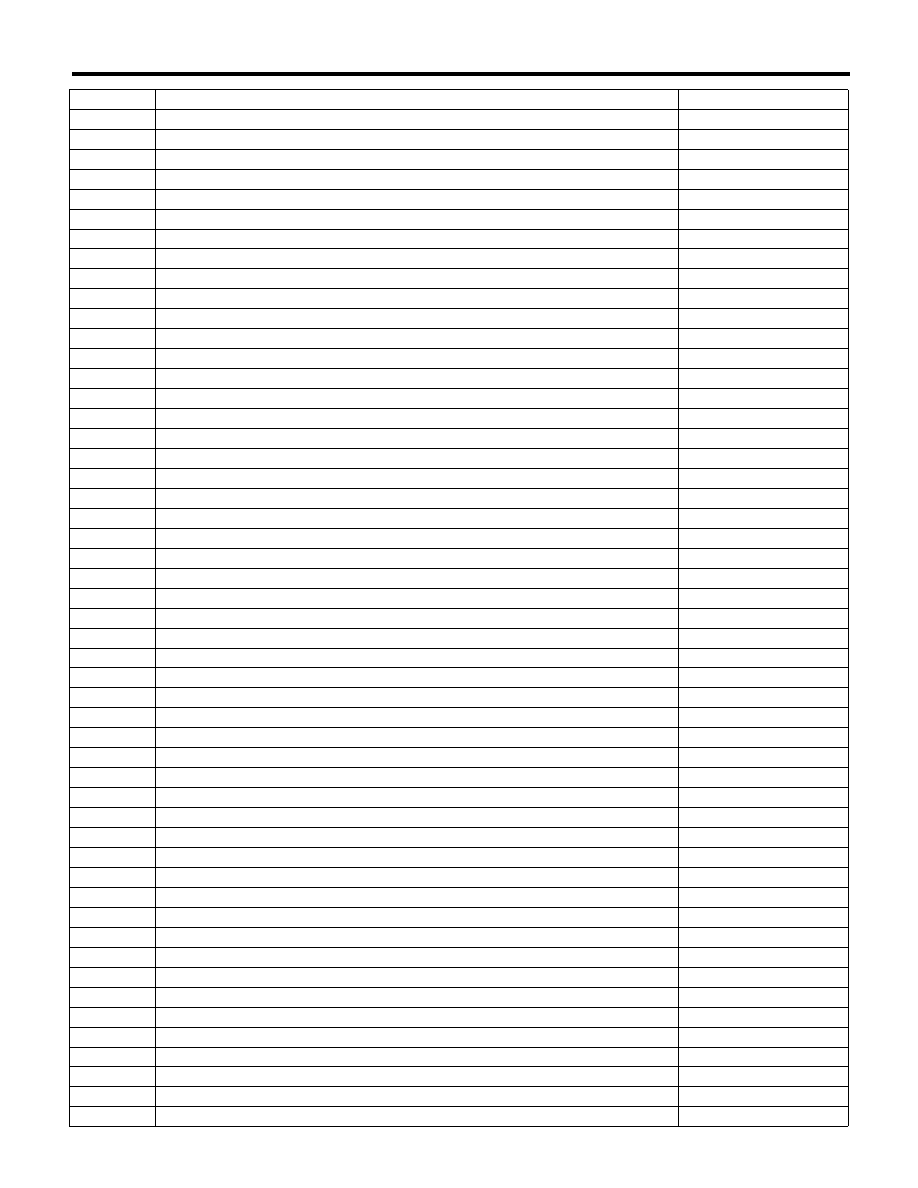

Inspection Mode

ENGINE (DIAGNOSTICS)

P0335

Crankshaft Position Sensor “A” Circuit

—

P0336

Crankshaft Position Sensor “A” Circuit Range/Performance

—

P0340

Camshaft Position Sensor “A” Circuit (Bank 1 or Single Sensor)

—

P0345

Camshaft Position Sensor “A” Circuit (Bank 2)

—

P0447

Evaporative Emission Control System Vent Control Circuit Open

—

P0448

Evaporative Emission Control System Vent Control Circuit Shorted

—

P0452

Evaporative Emission Control System Pressure Sensor Low Input

—

P0453

Evaporative Emission Control System Pressure Sensor High Input

—

P0458

Evaporative Emission System Purge Control Valve Circuit Low

—

P0462

Fuel Level Sensor “A” Circuit Low

—

P0463

Fuel Level Sensor “A” Circuit High

—

P0500

Vehicle Speed Sensor “A”

—

P0512

Starter Request Circuit

—

P0513

Incorrect Immobilizer Key

—

P0600

Serial Communication Link

—

P0604

Internal Control Module Random Access Memory (RAM) Error

—

P0605

Internal Control Module Read Only Memory (ROM) Error

—

P0607

Throttle Control System Circuit Range/Performance

—

P0638

Throttle Actuator Control Range/Performance (Bank 1)

—

P0700

Transmission Control System (MIL Request)

—

P1152

O2 Sensor Circuit Range/Performance (Low) (Bank1 Sensor1)

—

P1153

O2 Sensor Circuit Range/Performance (High) (Bank1 Sensor1)

—

P1154

O2 Sensor Circuit Range/Performance (Low) (Bank 2 Sensor 1)

—

P1155

O2 Sensor Circuit Range/Performance (High) (Bank 2 Sensor 1)

—

P1160

Return Spring Failure

—

P1400

Fuel Tank Pressure Control Solenoid Valve Circuit Low

—

P1420

Fuel Tank Pressure Control Sol. Valve Circuit High

—

P1560

Back-Up Voltage Circuit Malfunction

—

P1570

Antenna

—

P1571

Reference Code Incompatibility

—

P1572

IMM Circuit Failure (Except Antenna Circuit)

—

P1574

Key Communication Failure

—

P1576

EGI Control Module EEPROM

—

P1577

IMM Control Module EEPROM

—

P1578

Meter Failure

—

P2088

Intake Camshaft Position Actuator Control Circuit Low (Bank 1)

—

P2089

Intake Camshaft Position Actuator Control Circuit High (Bank 1)

—

P2092

Intake Camshaft Position Actuator Control Circuit Low (Bank 2)

—

P2093

Intake Camshaft Position Actuator Control Circuit High (Bank 2)

—

P2101

Throttle Actuator Control Motor Circuit Range/Performance

—

P2102

Throttle Actuator Control Motor Circuit Low

—

P2109

Throttle/Pedal Position Sensor “A” Minimum Stop Performance

—

P2122

Throttle/Pedal Position Sensor/Switch “D” Circuit Low Input

—

P2123

Throttle/Pedal Position Sensor/Switch “D” Circuit High Input

—

P2127

Throttle/Pedal Position Sensor/Switch “E” Circuit Low Input

—

P2128

Throttle/Pedal Position Sensor/Switch “E” Circuit High Input

—

P2135

Throttle/Pedal Position Sensor/Switch “A”/“B” Voltage Correlation

—

P2138

Throttle/Pedal Position Sensor/Switch “D”/“E” Voltage Correlation

—

P2227

Barometric Pressure Circuit Range/Performance

—

P2228

Barometric Pressure Circuit Low

—

P2229

Barometric Pressure Circuit High

—

DTC

Item

Condition