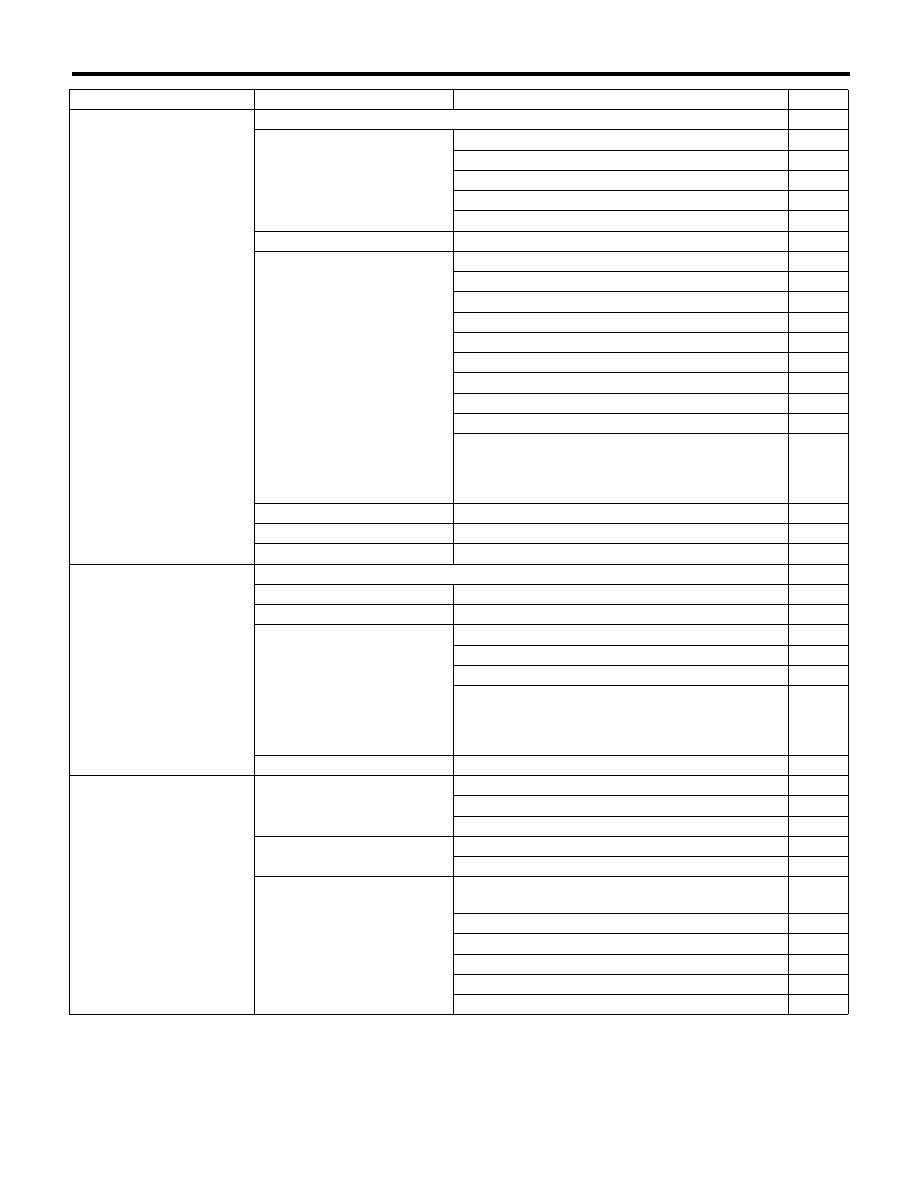

Subaru Legacy IV (2008 year). Manual - part 491

ME(H6DO)-90

Engine Trouble in General

MECHANICAL

7. After burning in exhaust

system

Engine control system <Ref. to EN(H6DO)(diag)-2, Basic Diagnostic Procedure.>

A

Intake system

Loosened or cracked intake duct

C

Loosened or cracked PCV hose

C

Loosened or cracked vacuum hose

B

Defective PCV valve

B

Loosened oil filler cap

C

Timing chain

Defective timing

B

Compression

Incorrect valve clearance

B

Loosened spark plug or defective gasket

C

Loosened cylinder head bolt or defective gasket

C

Improper valve sealing

B

Defective valve stem

C

Worn or broken valve spring

C

Worn or stuck piston rings, cylinder and piston

C

Incorrect valve timing

A

Trouble of valve lifter

C

Trouble of valve lifter. (In case noise occurs with valve

moving. Or the harness involved to oil switching sole-

noid valve, variable valve lift diagnosis oil pressure

switch and variable valve lift has trouble in a past.)

B

Lubrication system

Incorrect oil pressure

C

Cooling system

Over-cooling

C

Others

Evaporative emission control system malfunction

C

8. Knocking

Engine control system <Ref. to EN(H6DO)(diag)-2, Basic Diagnostic Procedure.>

A

Intake system

Loosened oil filler cap

B

Timing chain

Defective timing

B

Compression

Incorrect valve clearance

C

Incorrect valve timing

B

Trouble of valve lifter

C

Trouble of valve lifter. (In case noise occurs with valve

moving. Or the harness involved to oil switching sole-

noid valve, variable valve lift diagnosis oil pressure

switch and variable valve lift has trouble in a past.)

B

Cooling system

Over-heating

A

9. Excessive engine oil con-

sumption

Intake system

Loosened or cracked PCV hose

A

Defective PCV valve

B

Loosened oil filler cap

C

Compression

Defective valve stem

A

Worn or stuck piston rings, cylinder and piston

A

Lubrication system

Loosened oil pump attaching bolts and defective gas-

ket

B

Defective oil filter O-ring

B

Defective crankshaft oil seal

B

Defective rocker cover gasket

B

Loosened oil drain plug or defective gasket

B

Loosened oil pan fitting bolts or defective oil pan

B

Symptoms

Problem parts etc.

Possible cause

RANK