Subaru Legacy IV (2008 year). Manual - part 486

ME(H6DO)-70

Cylinder Block

MECHANICAL

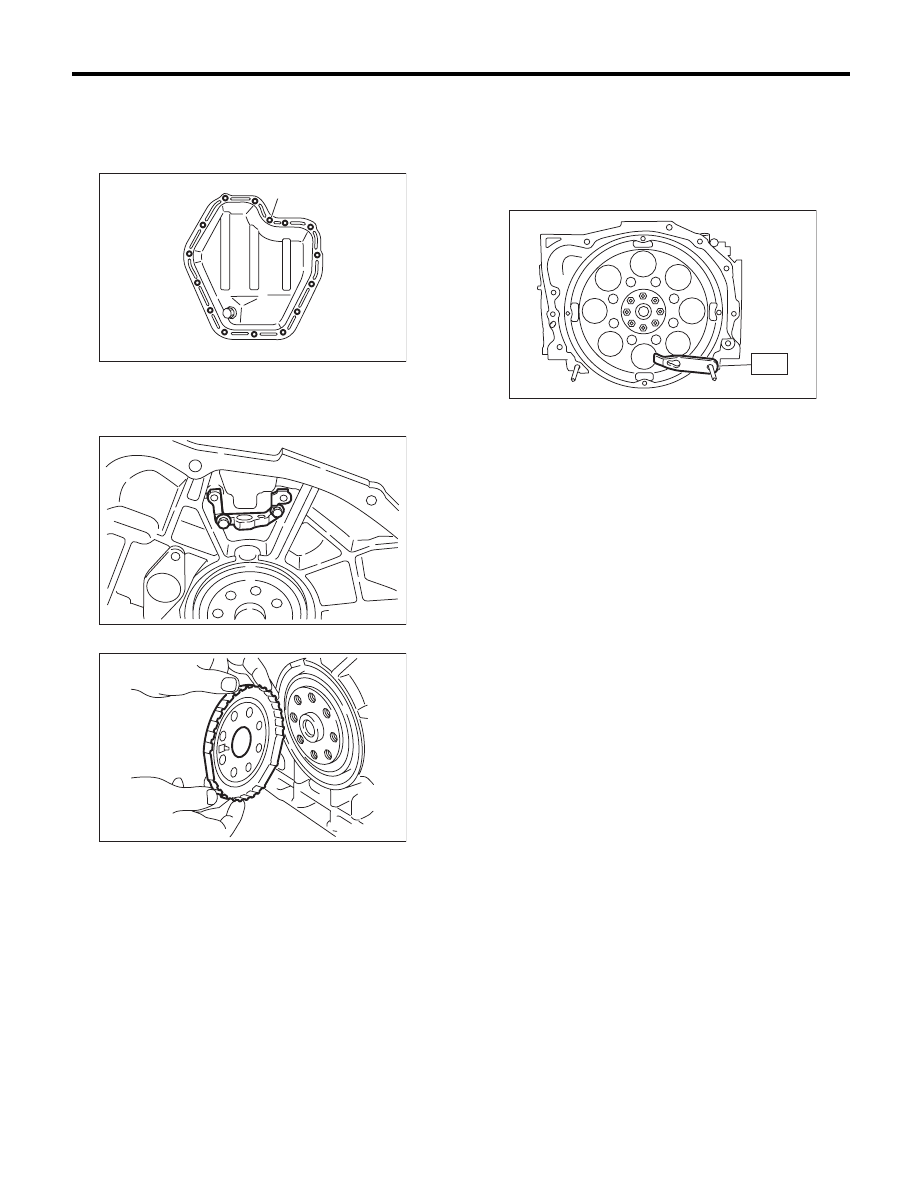

24) Tighten the oil pan lower installing bolts in the

numerical order as shown in the figure.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

25) Attach the crankshaft position sensor holder.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

26) Install the crankshaft sensor plate.

27) Use the ST to lock the crankshaft, and install

the drive plate.

ST1

498497100

CRANKSHAFT STOPPER

ST2

499057000

TORX PLUS

®

Tightening torque:

81 N·m (8.3 kgf-m, 59.7 ft-lb)

28) Install the cylinder head. <Ref. to ME(H6DO)-

59, INSTALLATION, Cylinder Head.>

29) Install the camshaft. <Ref. to ME(H6DO)-56,

INSTALLATION, Camshaft.>

30) Install the rear chain cover. <Ref. to

ME(H6DO)-53, INSTALLATION, Rear Chain Cov-

er.>

31) Install the crank sprocket. <Ref. to ME(H6DO)-

52, INSTALLATION, Crank Sprocket.>

32) Install the cam sprocket. <Ref. to ME(H6DO)-

51, INSTALLATION, Cam Sprocket.>

33) Install the timing chain assembly. <Ref. to

ME(H6DO)-47, INSTALLATION, Timing Chain As-

sembly.>

34) Install the front chain cover. <Ref. to

ME(H6DO)-44, INSTALLATION, Front Chain Cov-

er.>

35) Install the crank pulley. <Ref. to ME(H6DO)-43,

INSTALLATION, Crank Pulley.>

36) Install the V-belts. <Ref. to ME(H6DO)-42, IN-

STALLATION, V-belt.>

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

ME-00582

ME-00559

ME-00558

ST

ME-00557