Subaru Legacy IV (2008 year). Manual - part 126

EN(H4SO)(diag)-107

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

K: DTC P0082 INTAKE VALVE CONTROL SOLENOID CIRCUIT LOW (BANK 2)

DTC DETECTING CONDITION:

• Immediately at fault recognition

• GENERAL DESCRIPTION <Ref. to GD(H4SO)-25, DTC P0082 INTAKE VALVE CONTROL SOLENOID

CIRCUIT LOW (BANK 2), Diagnostic Trouble Code (DTC) Detecting Criteria.>

TROUBLE SYMPTOM:

Improper idling

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode <Ref. to EN(H4SO)(diag)-50,

OPERATION, Clear Memory Mode.>, and Inspection Mode <Ref. to EN(H4SO)(diag)-41, PROCEDURE,

Inspection Mode.>.

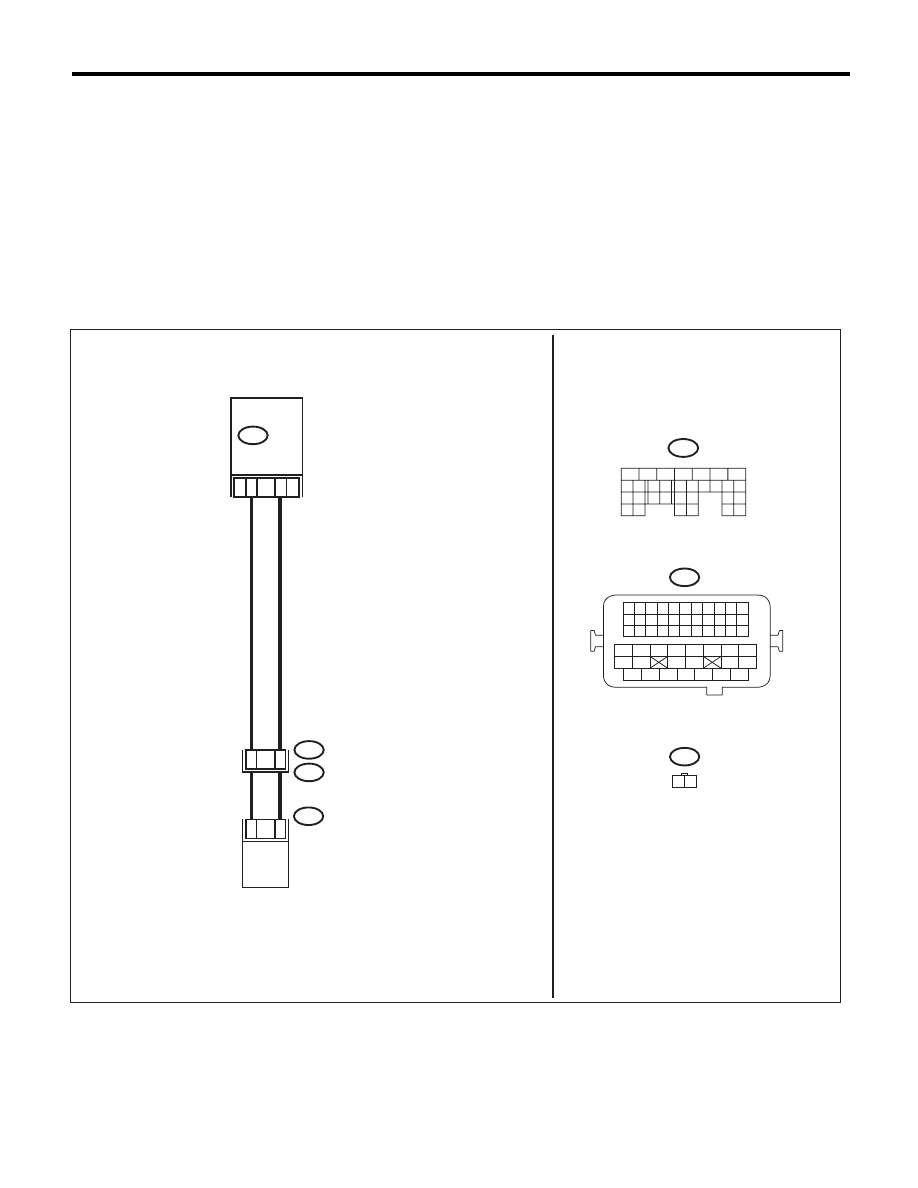

WIRING DIAGRAM:

EN-05705

B21

E2

B137

E68

30

2

1

28

27

E68

B21

1 2

31

B137

1 2 3 4

12 13 14 15

5 6 7 8

16 17 18 19

9 10 11

20 21 22

23 24 25 26 27 28 29 30 31 32 33

35

34

37

36

39

38

41

40

43

42

44

45

47

46

49

48

51

50

53

52

54

5

6

7

8

2

1

9

4

3

10

22 23

11 12 13 14 15

24 25

26

16 17

18 19 20 21

27

28 29

30 31

ECM

OIL SWITCHING SOLENOID VALVE LH