Content .. 1131 1132 1133 1134 ..

Subaru Legacy IV (2008 year). Manual - part 1133

EI-31

Front Bumper

EXTERIOR/INTERIOR TRIM

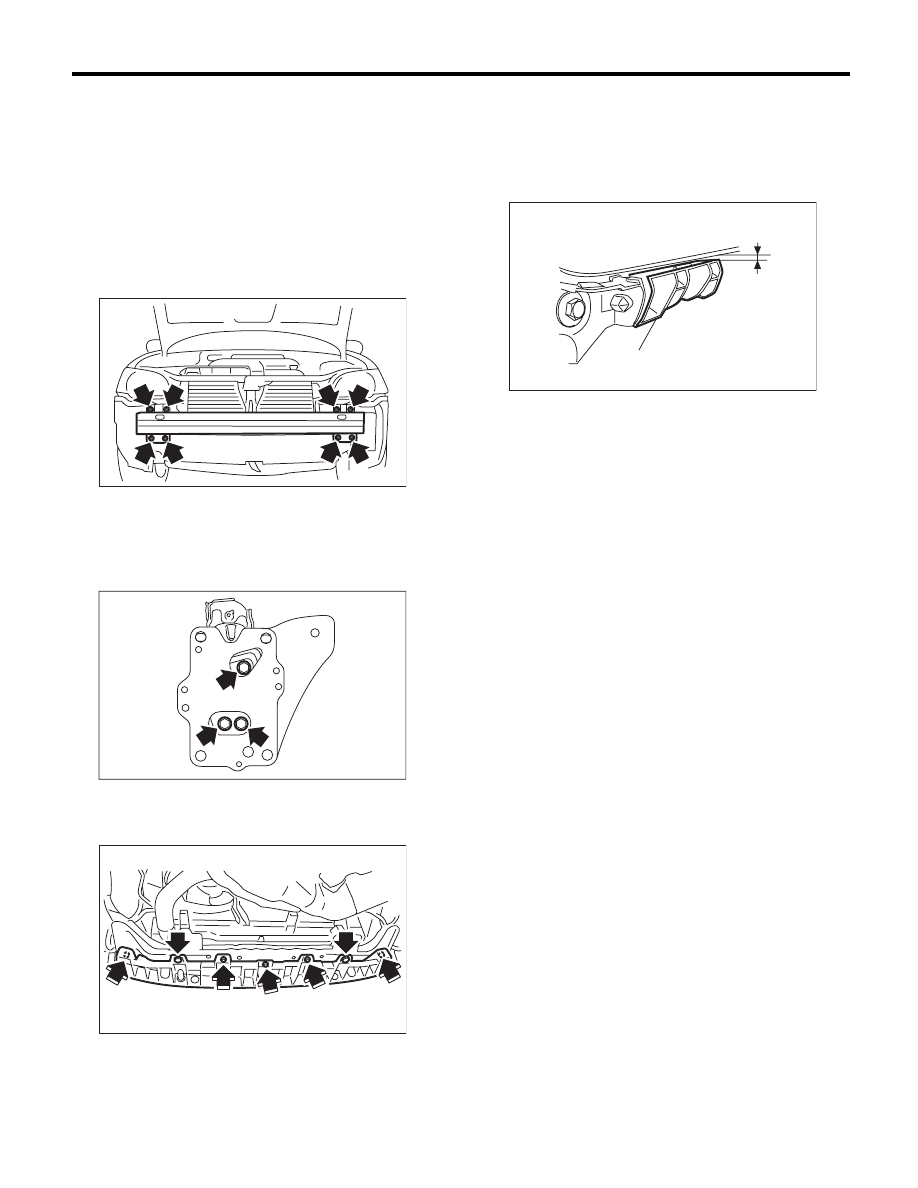

2. FRONT BUMPER BEAM ASSEMBLY

1) Disconnect the ground cable from the battery.

2) Remove the front bumper face. <Ref. to EI-30,

FRONT BUMPER FACE, REMOVAL, Front

Bumper.>

3) Remove the energy absorber foam from bumper

beam.

4) Remove the headlight assembly. <Ref. to LI-13,

REMOVAL, Headlight Assembly.>

5) Remove the bolts, and remove the bumper

beam assembly from vehicle body.

NOTE:

After all bolts are removed, raise the whole bumper

beam a little to remove it from vehicle body.

6) Remove the bolts and nuts, and disassemble the

bumper beam.

7) Remove the under cover.

8) Remove the bolts and clips, and remove the ra-

diator guide.

B: INSTALLATION

1. FRONT BUMPER FACE

1) Install in the reverse order of removal.

2) Fit the bumper face to the gap (B) between the

guide bracket (A) and fender securely.

3) Replace the double-sided tape with new one,

and install it to the side garnish.

2. FRONT BUMPER BEAM ASSEMBLY

Install in the reverse order of removal.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion”. <Ref. to EI-5, FRONT BUMPER, COM-

PONENT, General Description.>

EI-01724

EI-01023

EI-00578

EI-01725

(A)

(B)