Subaru Legacy IV (2008 year). Manual - part 26

PM-44

Suspension

PERIODIC MAINTENANCE SERVICES

20.Suspension

A: INSPECTION

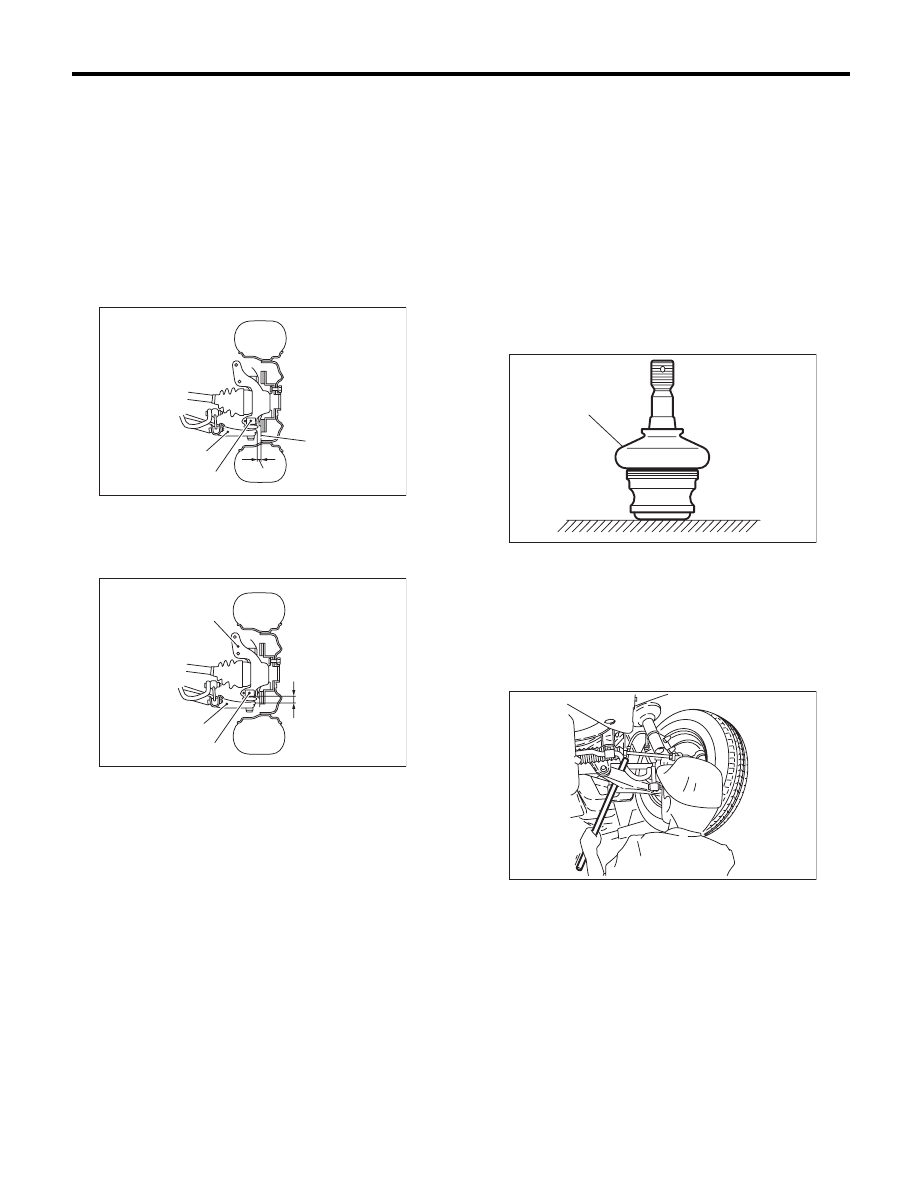

1. SUSPENSION BALL JOINT

1) Jack-up the vehicle until front wheels are off

ground.

2) Grasp the bottom of tire and move it in and out in

axial direction. If relative movement (B) is observed

between the brake disc cover (A) and the end of

front arm (D), ball joint (C) may be excessively

worn.

3) Grasp the end of front arm and move it up and

down. Relative movement (A) between the housing

(D) and front arm (C) boss indicates ball joint (B)

may be excessively worn.

4) If relative movement is observed in the step 2),

3), remove and inspect the ball joint. If the free play

exceeds standard value, replace the ball joint.

<Ref. to FS-16, Front Ball Joint.>

5) Damage of dust seal

Visually inspect the ball joint dust seal. If it is dam-

aged, remove the front arm. <Ref. to FS-18, Front

Arm.> Also, measure the free play of the ball joint.

<Ref. to FS-16, Front Ball Joint.>

(1) If the free play exceeds standard value, re-

place the ball joint.

(2) If the dust seal is damaged, replace with a

new ball joint.

NOTE:

When the front arm ball joint has been removed or

replaced, check the toe of front wheel. If the front

wheel toe-in is not at the specified value, adjust the

toe-in. <Ref. to FS-6, Wheel Alignment.>

2. FRONT, REAR SUSPENSION BUSHING

Apply pressure with tire lever etc. to inspect the

bushing for abnormal fatigue or damage. Replace

the bushings if there is abnormal fatigue or dam-

age.

PM-00057

(A)

(B)

(C)

(D)

PM-00058

(A)

(B)

(C)

(D)

(A) Dust seal

PM-00059

(A)

PM-00180