SsangYong Rexton. Manual - part 554

AUTOMATIC TRANSMISSION 5A-191

SSANGYONG Y200

KAA5A1GO

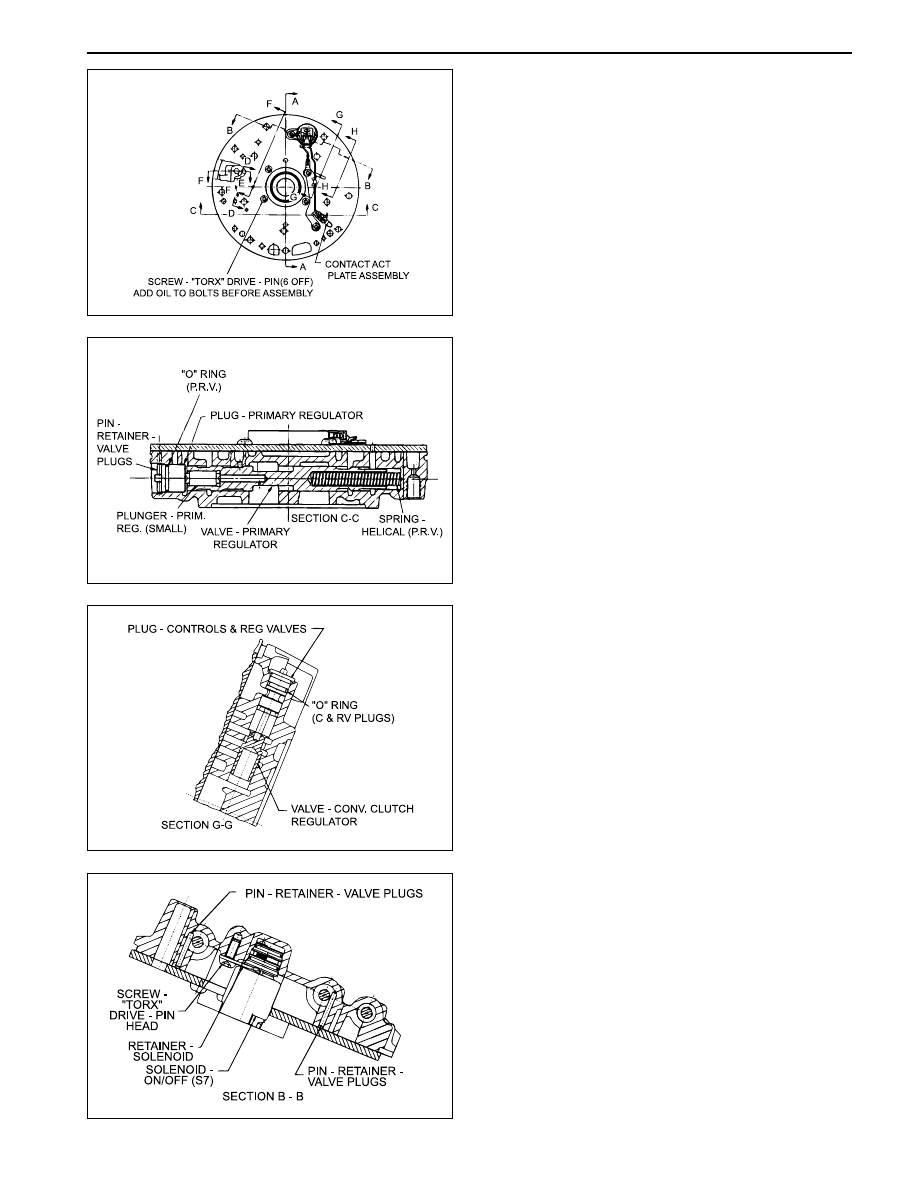

11. Install the converter clutch regulator valve, plug,

spring and ‘O’ ring.

12. Install the retaining pin.

9. Assemble the primary regulator valve, spring and

plunger to the pump cover, ensuring that the

regulator valve slides freely, then fit the regulator

valve plug and ‘O’ ring.

10. Install the retaining pin.

KAA5A1F0

KAA5A1G0

KAA5A1E0

7. Ensure that the pump cover cavities, ports and

holes are clean and free of any obstruction.

8. L u b r i c a t e a l l l o o s e p a r t s w i t h a u t o m a t i c

transmission fluid prior to assembly.

KAA5A1D0