SsangYong Rexton. Manual - part 547

AUTOMATIC TRANSMISSION 5A-163

SSANGYONG Y200

KAA5A500

KAA5A510

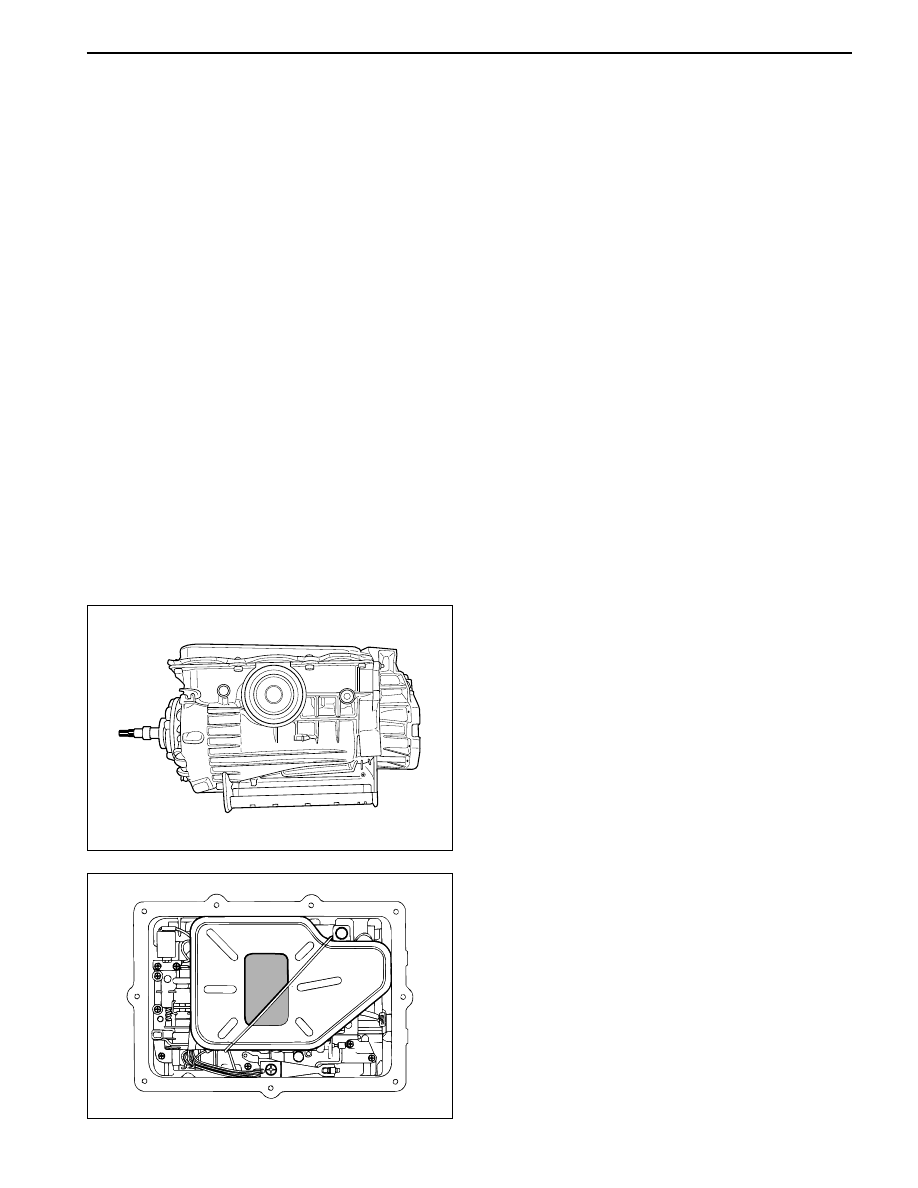

DISASSEMBLY PROCEDURE

Transmission

Tools Required

0555-336256 Transmission Bench Cradle

0555-336257 Pump Puller

Notice:

•

Remove the inhibitor switch before washing the

transmission in solvent or hot wash.

•

It is assumed that the transmission fluid has been

drained when the transmission was removed from

the vehicle and that the ’special tools’ quoted are

available.

•

The transmission is dismantled in a modular fashion,

and the details of disassembly for each module are

given under the appropriate subject. Refer to

Special Tools Table in this chapter for details of all

special

t o o l s r e q u i r e d w h e n p e r f o r m i n g

disassembly procedures.

•

Technicians overhauling these transmissions will

also require a selection of good quality Torx bit

sockets, in particular numbers 30, 40 and 50, and

an 8mm, 10mm and 12 mm double hex socket.

1. Remove the converter and the converter housing.

2. Mount the transmission on the transmission bench

cradle 0555-336256.

3. Remove the oil pan and the oil pan seal.

4. Remove each end of the filter retaining clip from

the valve body and remove the filter.

5. Disconnect the wires from each solenoid and ground

and lay the wiring to one side.

6. Remove the valve body securing screws and

remove the valve body from the case.