SsangYong Rexton. Manual - part 534

AUTOMATIC TRANSMISSION 5A-7

SSANGYONG Y200

Solenoids

The TCM controls seven solenoids. Solenoids 1 to 6

(S1 to S6) are mounted in the valve body, while

Solenoid 7 (S7) is mounted in the pump cover.

•

Solenoid 1 and 2: S1 and S2 are normally open ON/

OFF solenoids that set the selected gear. These

solenoids determine static gear position by

operating the shift valves. Note that S1 and S2

solenoids also send signal pressure to allow or

prohibit rear band engagement.

•

Solenoid 3 and 4: S3 and S4 are normally open ON/

OFF solenoids that combine to control shift quality

and sequencing. S3 switches the clutch regulator

valve OFF or ON. S4 switches the front band regula-

tor valve OFF or ON. S5 also provides the signal

pressure for the converter clutch regulator valve.

•

Solenoid 5: S5 is a variable pressure solenoid that

ramps the pressure during gear changes. This sole-

noid provides the signal pressure to the clutch and

band regulator, thereby controlling the shift pres-

sures. S5 also provides the signal pressure for the

converter clutch regulator valve.

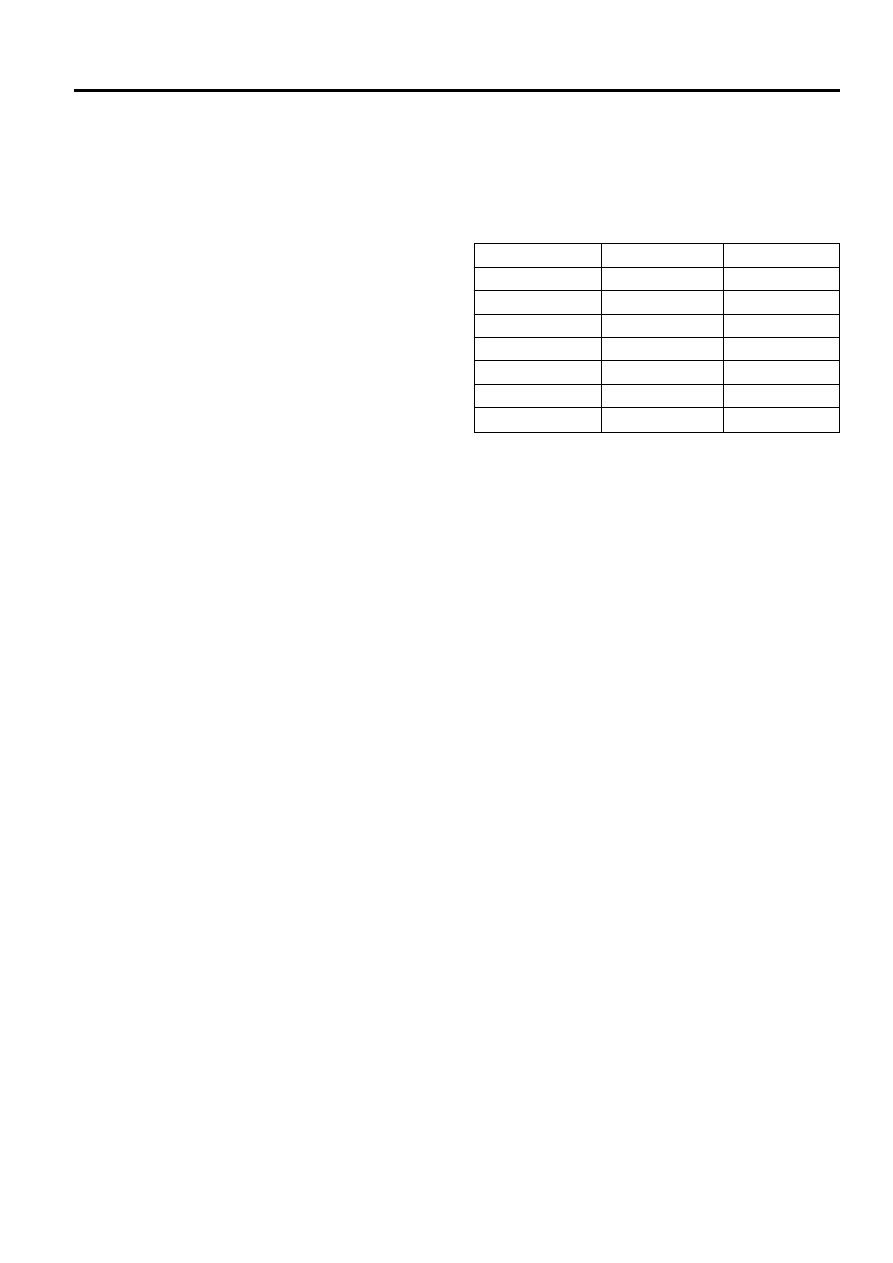

Gear

S1

S2

1st

ON

ON

2 n d

OFF

ON

3 r d

OFF

OFF

4 t h

ON

OFF

Reverse

OFF

OFF

Neutral

OFF

OFF

Park

OFF

OFF

•

Solenoid 6: S6 is a normally open ON/OFF solenoid

that sets the high/low level of line pressure. Solenoid

OFF gives high pressure.

•

Solenoid 7: S7 is a normally open ON/OFF solenoid

that controls the application of the converter clutch.

Solenoid ON activates the clutch.

Solenoid Logic for Static Gear States