SsangYong Rexton. Manual - part 516

ABS AND TCS 4E-25

SSANGYONG Y200

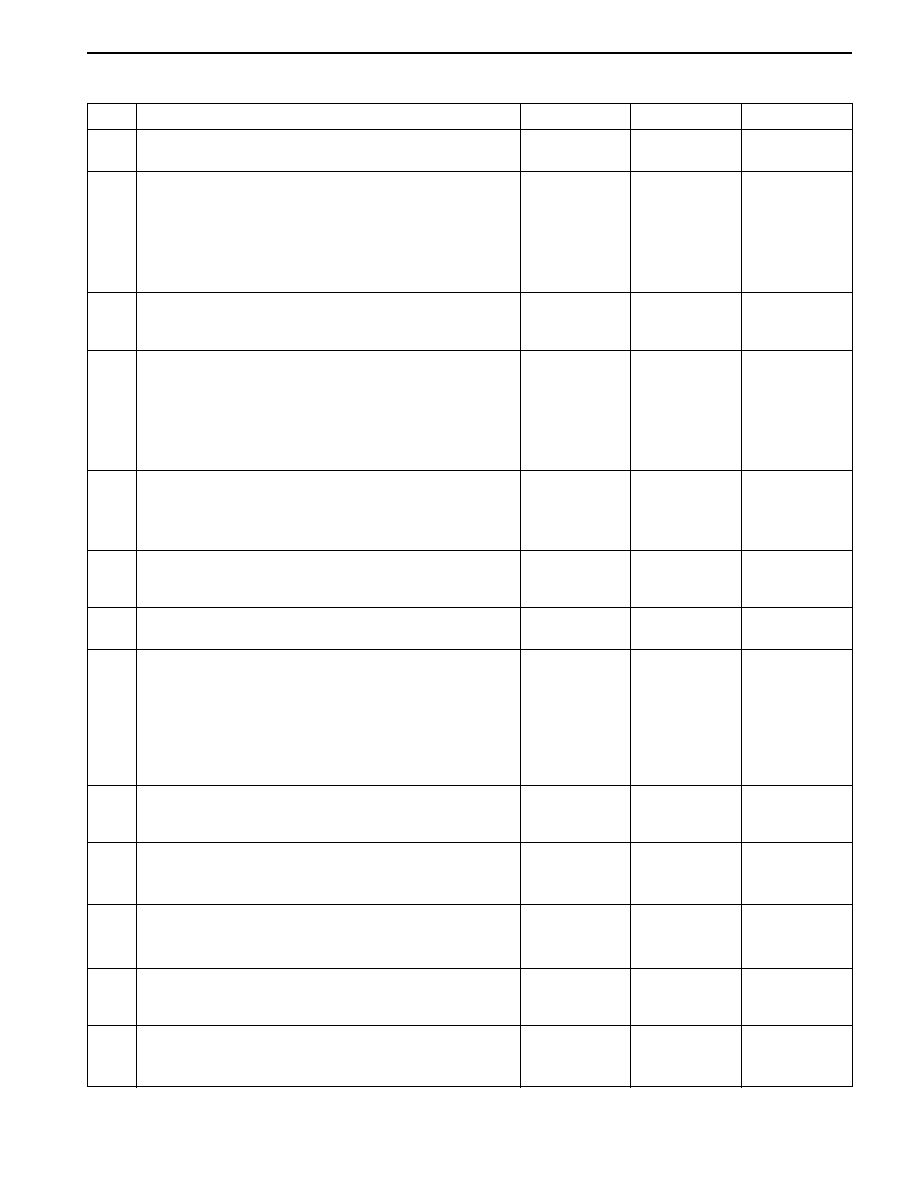

Install the scan tool and check for any DTCs.

Is any DTC set?

1. Turn the ignition to LOCK.

2. Disconnect the scan tool.

3. Turn the ignition to ON.

4. Observe the TCS indicator lamp.

Does the lamp illuminate for about 2 seconds, then

turn off?

With the ignition still ON, observe the oil pressure

lamp.

Is the oil pressure lamp illuminated?

1. Turn the ignition to LOCK.

2. Disconnect the connector from the EBCM.

3. Connect a jumper form terminal 22 to the grounding

bar in the connector.

4. Turn the ignition to ON.

Does the TCS indicator illuminate?

1. Turn the ignition to LOCK.

2. Examine terminals 16, 19 at the EBCM connector

on both the ABS wiring harness and on the EBCM.

Is there a poor connection at any of these terminals?

Repair the faulty terminals or replace the ABS unit, as

required.

Is the repair complete?

Replace the ABS unit.

Is the repair complete?

1. Turn the ignition to LOCK.

2. Disconnect the wire from the negative battery

terminal.

3. Measure the resistance between the negative

battery wire, which is attached to ground, and the

shorting bar in the EBCM connector.

Is the resistance equal to the specified value?

Repair the open or high resistance in the circuit from

EBCM connector, terminal 16, 19 to ground G106.

Is the repair complete?

1. Remove the I/P cluster.

2. Remove and check the TCS indicator bulb.

Is the bulb burned out?

1. Replace the TCS indicator bulb.

2. Replace the I/P cluster.

Is the repair complete?

Check continuity at the I/P cluster connector terminal

B10.

Is the continuity equal to the specified value?

Repair the contact at the I/P cluster connector terminal

B10.

Is the repair complete?

Traction Control System (TCS) Indicator Lamp Inoperative

Step

1

Action

Yes

No

Value

2

Go to the

DTC table

Go to Step 2

-

Go to

“Intermittent

and Poor

Connections”

Go to Step 3

-

3

Go to Step 4

Go to Step 19

-

4

Go to Step 5

Go to Step 8

-

5

Go to Step 6

Go to Step 7

-

6

7

8

Go to Step 10

Go to Step 9

≈

0

Ω

9

System OK

-

-

10

Go to Step 11

Go to Step 12

-

11

System OK

-

-

12

Go to Step 14

Go to Step 13

≈

0

Ω

13

System OK

-

-

System OK

-

-

System OK

-

-