SsangYong Rexton. Manual - part 442

SSANGYONG Y200

1F2-94 M161 ENGINE CONTROLS

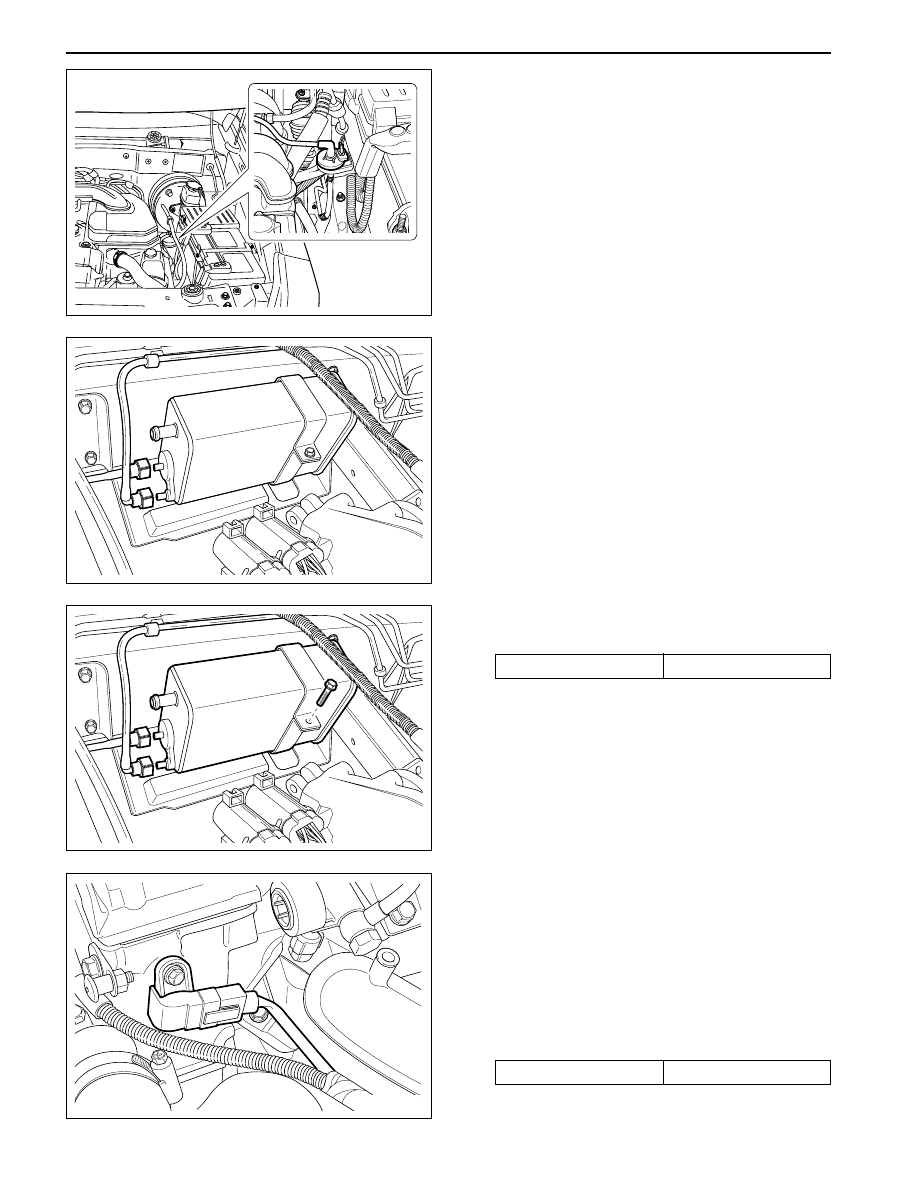

PURGE CONTROL VALVE

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the purge control valve connector.

3. Disconnect the throttle body-to-purge control valve

hose from the purge control valve.

4. Disconnect the canister-to-purge control valve

hose from the purge control valve.

5. Remove the purge control valve.

6. Installation should follow the removal provedure

in the reverse order.

YAA1F800

YAD1F670

YAA1F810

3. Remove the canister mounting bolts.

Installation Notice

CAMSHAFT POSITION SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector from the cam-

shaft position sensor.

3. Remove the camshaft position sensor retaining

bolt.

Installation Notice

YAD1F660

CANISTER

Removal and Installation Procedure

Caution: Canister and vacuum hoses contain fuel

vapors. Do not smoke in the area or permit an open

flame.

1. Disconnect the fuel tank-to-canister hose form the

canister.

2. Disconnect the canister-to-purge control valve

hose form the canister.

Tightening Torque

6 N•m (53 lb-in)

4. Remove the canister.

5. Installation should follow the removal procedure

in the reverse order.

Tightening Torque

10 N•m (89 lb-in)