SsangYong Rexton. Manual - part 393

DIESEL ENGINE MECHANICAL 1B3-147

SSANGYONG Y200

YAD1BJS0

YAD1BJT0

YAD1BJU0

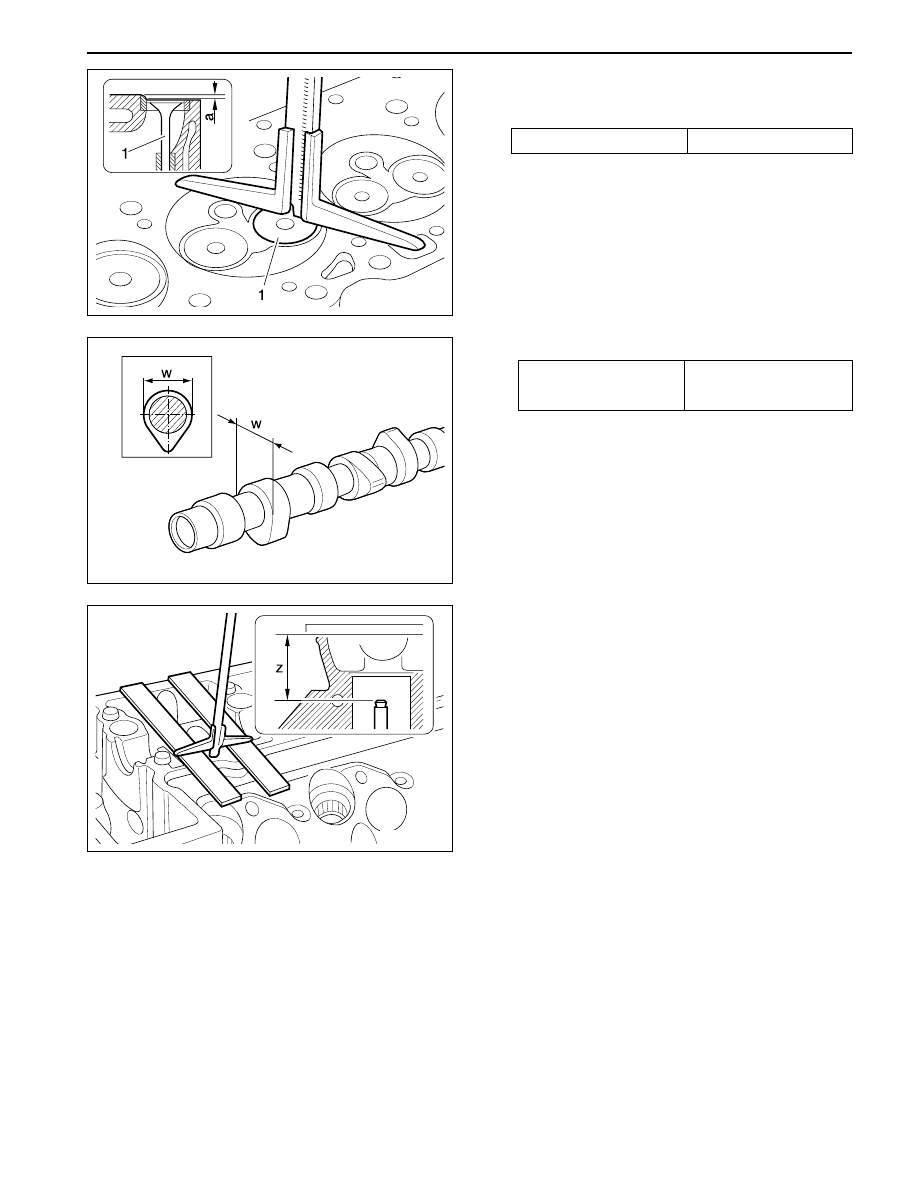

5. Insert the valve (1) into the valve guide according

to marking and measure amount by which the

valve arrears ‘a’.

7. Measure distance ‘z’ (cylinder head cover parting

surface - valve stem).

Arrears ‘a’

0.1 - 0.7 mm

38 ± 0.2 mm

or 37.6 ± 0.2 mm

Diameter ‘w’

6. Measure camshaft cam basic circle diameter (w).