SsangYong Rexton. Manual - part 374

SSANGYONG Y200

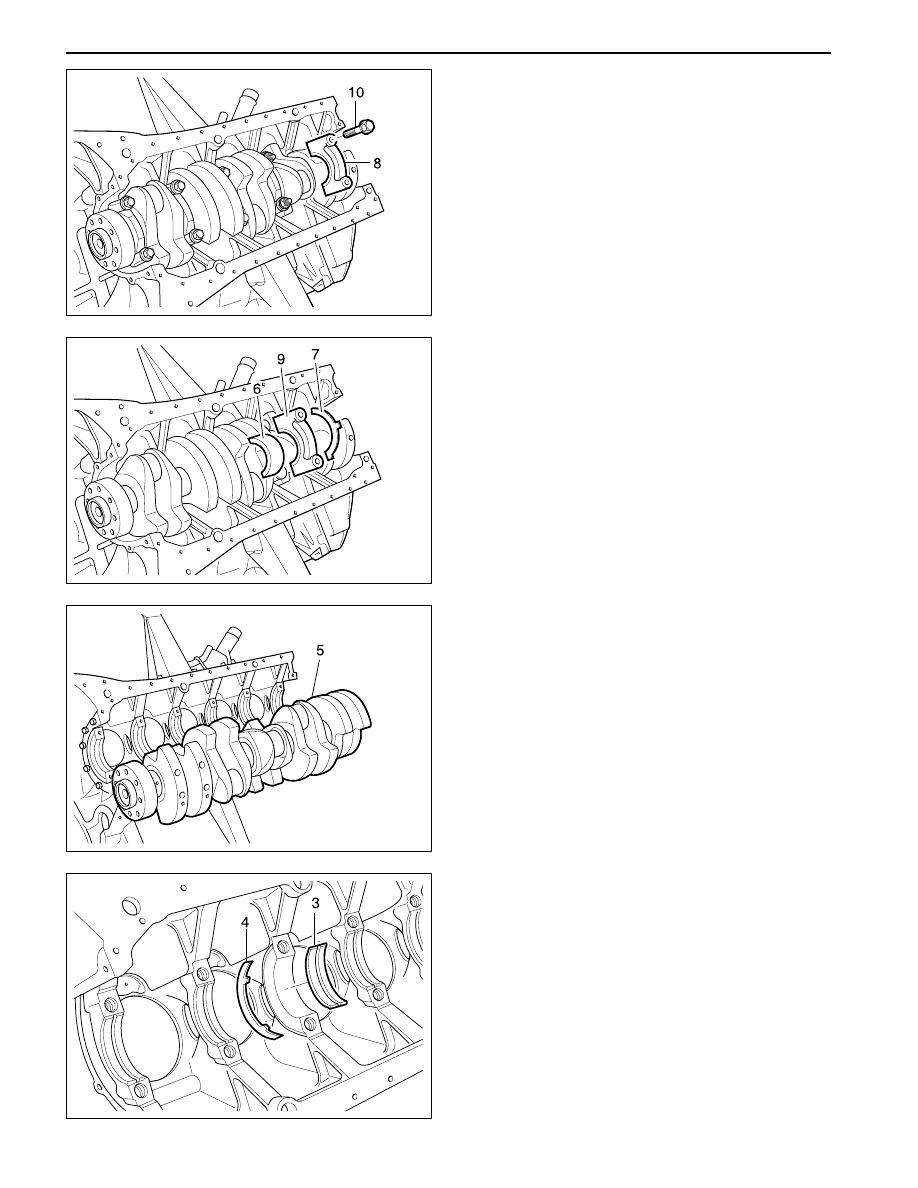

1B3-72 DIESEL ENGINE MECHANICAL

YAD1BEM0

YAD1BEN0

YAD1BEP0

YAD1BEQ0

Tools required

001 589 53 21 00

Dial Gauge

363 589 02 21 00

Dial Gauge Holder

366 589 00 21 05

Extension

Removal & Installation Procedure

1. Remove the bearing cab bolt.

2. Remove the bearing caps (8).

Notice: The crankshaft bearing caps are marked

with stamped numbers. Remove the bearing cap

from the vibration damper side.

3. Remove the crankshaft bearing caps (9) and lower

thrust bearings (7).

4. Remove the lower bearing shell (6) from the bearing

cap (9).

6. Remove the upper thrust bearings (4).

7. Remove the upper bearing shells (3) from

crankcase.

5. Remove the crankshaft (5).