SsangYong Rexton. Manual - part 349

M161 ENGINE MECHANICAL 1B2-79

SSANGYONG Y200

PISTON

Preceding Work:

Removal of engine

Removal of cylinder head

Removal of oil pan

Removal of oil pump

Removal of baffle plate

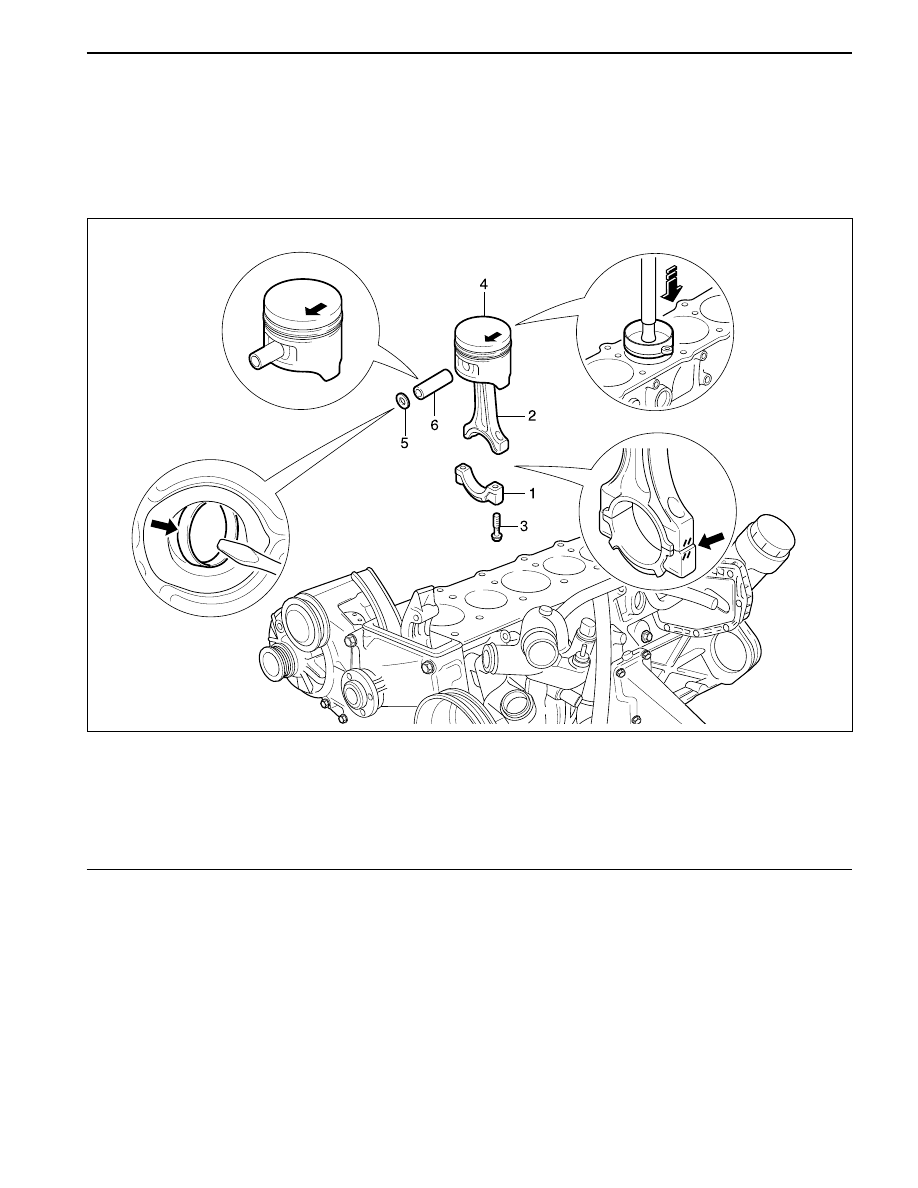

1 Connecting Rod Bearing Cap

2 Connecting Rod

3 Connecting Rod Bolt (M9 x 52, 8 pieces)

.................................. 1st step 40 N•m (30 lb-ft)

2nd step 90 °

YAD1B2R0

4 Piston

5 Snap Ring

6 Piston Pin