SsangYong Rexton. Manual - part 49

DI04-9

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

EXHAUST SYSTEM

DI ENG SM - 2004.4

Y220_04012

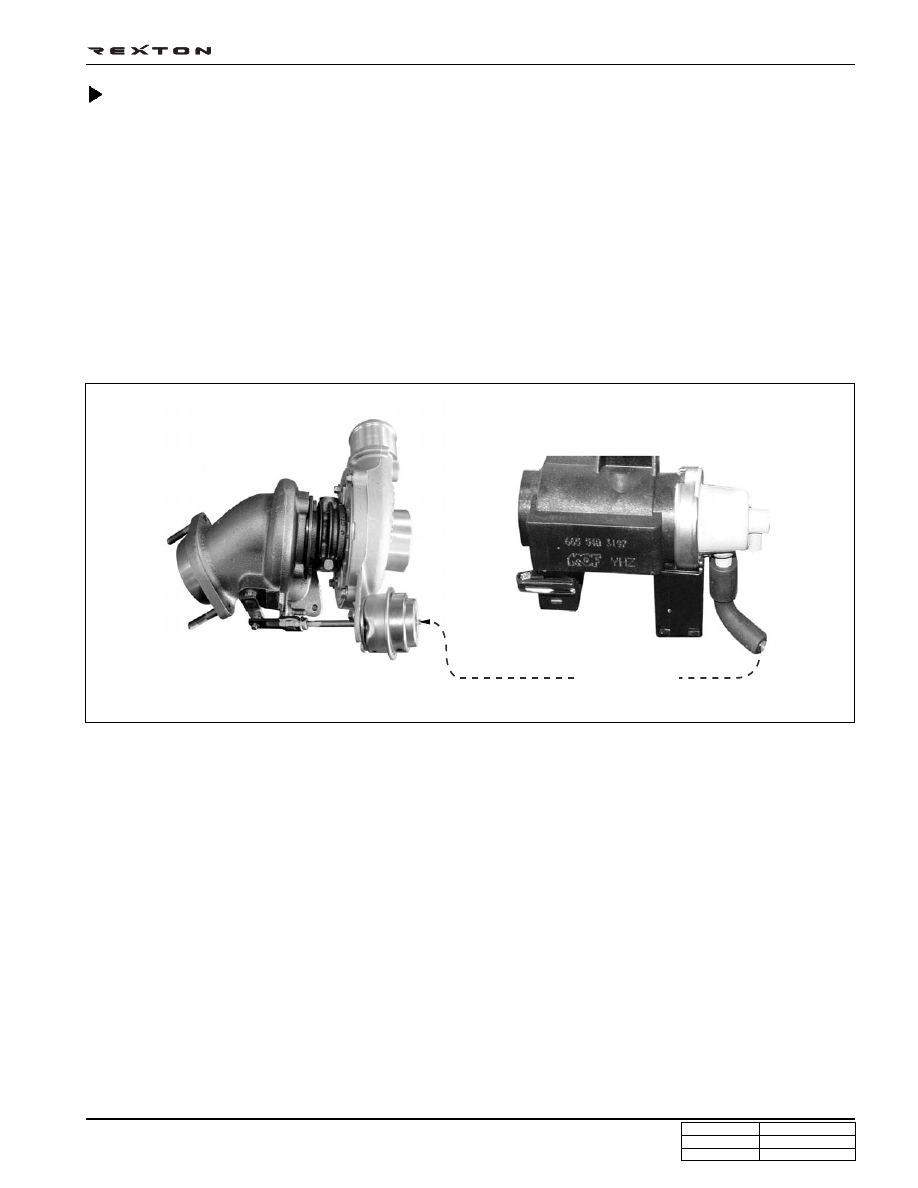

Booster Pressure Control Valve Unit (Turbo Charger Actuator)

In order to reduce discharging of hazardous exhaust gas and to avoid the engine’s overrun the turbo charger must be

appropriately controlled. The maximum turbo charging pressure must be controlled as excessive increase in the pres-

sure and power output can cause critical damages to the engine. In order to control these, the booster pressure control

valve is installed on the turbo charger.

The difference of the booster pressure control between the existing IDI engine and DI engine is that in IDI engine, booster

pressure of the intake manifold operates the booster pressure control valve connected directly to the turbo charger

whereas in DI engine, the control is achieved by utilizing vacuum modulator (vacuum from a vacuum pump) designed to

control the booster pressure control valve. It operates booster pressure control valve by supplying electrical power to the

vacuum modulator having the amount of air being flown into the HFM sensor from the engine’s ECU as the base signal.

Refer to the EGR section in following pages for the function of turbo charger and HFM sensor in exhaust system.

Booster pressure control valve unit and vacuum modulator

Turbo charger booster

Turbo charger booster

vacuum modulator