SsangYong Rexton. Manual - part 3

DI0A-5

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

6. Follow the job procedures. If you find a defective component, replace it with new one.

Y220_0A039

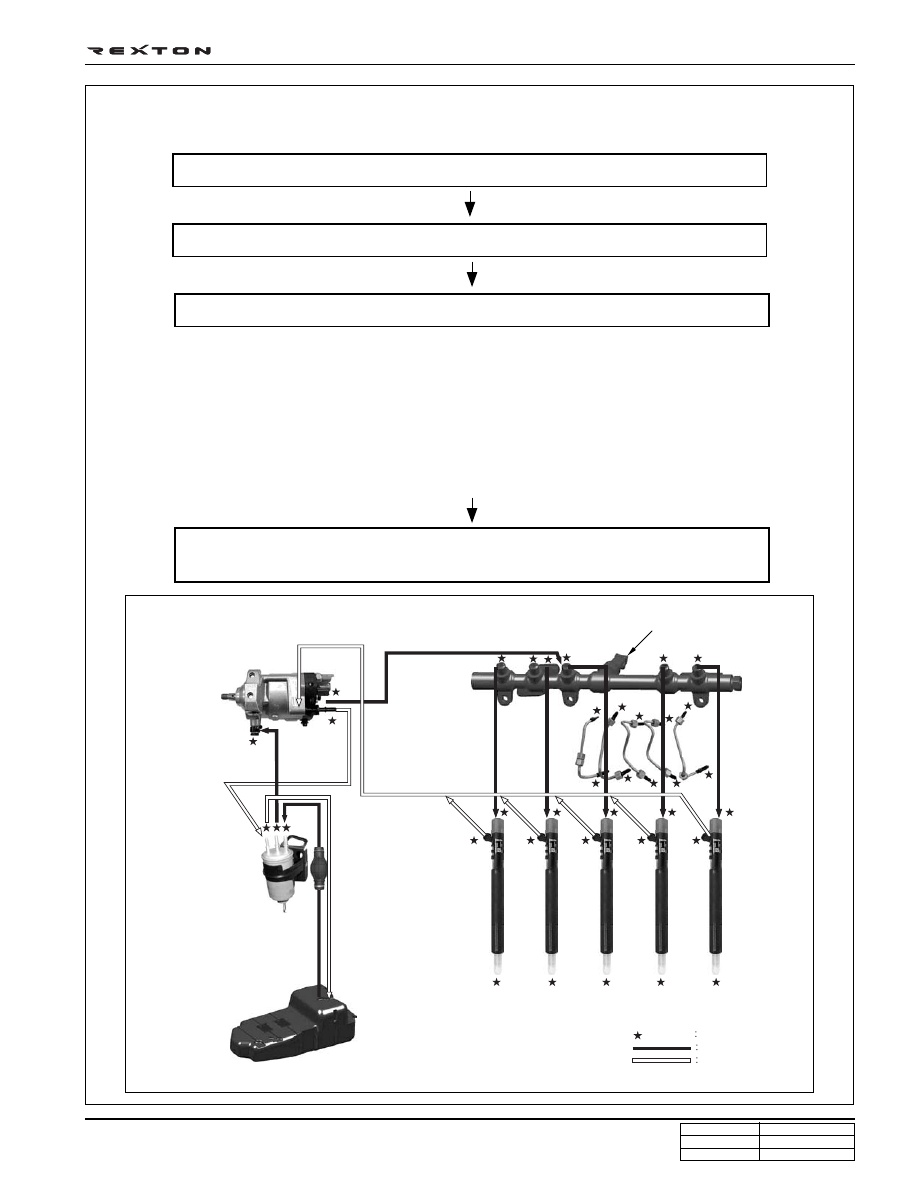

Fuel pressure sensor

Common rail

Injection

pipe

Injector

High pressure pump

IMV valve

Transfer pump and high

pressure pump

Fuel temperature sensor

Fuel tank

Fuel filter

Priming

pump

Water separator

Water detection sensor

Disconnect the negative battery cable.

Plug the disconnected parts with sealing caps, and remove the caps immediately

before replacing the components.

Once disconnected, the fuel pipes between HP pump and fuel rail and between fuel rail

and each injector should be replaced with new ones. The pipes should be tightened to

specified tightening torques during installation. Over or under torques out of specified

range may cause damages and leaks at connections. Once installed, the pipes have been

deformed according to the force during installtion, therefore they are not reusable.

The copper washer on injector should be replaced with new one. The injector holder bolt

should be tightened to specified tightening torque as well. If not, the injection point may be

deviated from correct position, and it may cause engine disorder.

Supply line

Return line

Cap position

Use special tools and torque wrench to perform the correct works.

For safety reasons: check pressure is low before opening the HP systems (pipes)