SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 109

DI04-29

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

EXHAUST SYSTEM

DI ENG SM - 2004.9

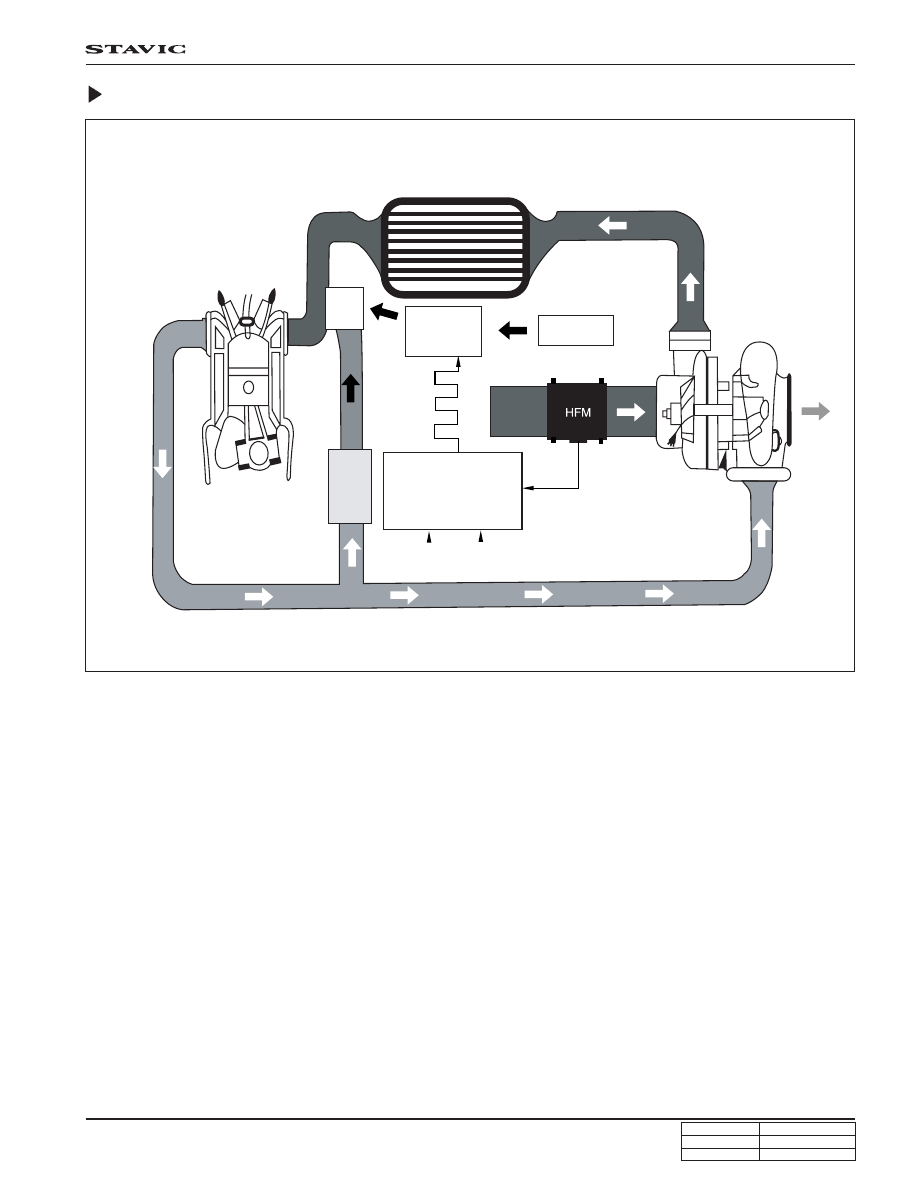

EGR System Diagram

EGR Valve

EGR valve recirculates some of exhaust gases to intake system to reduce toxic NOx from engine according to ECU

signals.

• EGR valve opening point : -270 mmHg

EGR Modulator

According to ECU signals, the vacuum modulator drives EGR valve by controlling vacuum pressure that is generated by

vacuum pump with PWM type controls.

Intercooler

Exhaust

manifold

Intake

manifold

EGR

valve

Regulated

vacuum

pressure

Modulator

Vacuum

pump

Duty

control

Feedback EGR

(Air Mass)

ECU

Improved target EGR

Air intake signal

(for EGR feed-

back control)

Turbo charger

Pedal

signal

RPM

signal