SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 29

1B-100

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE MECHANICAL

M162 GSL ENG SM - 2005.7

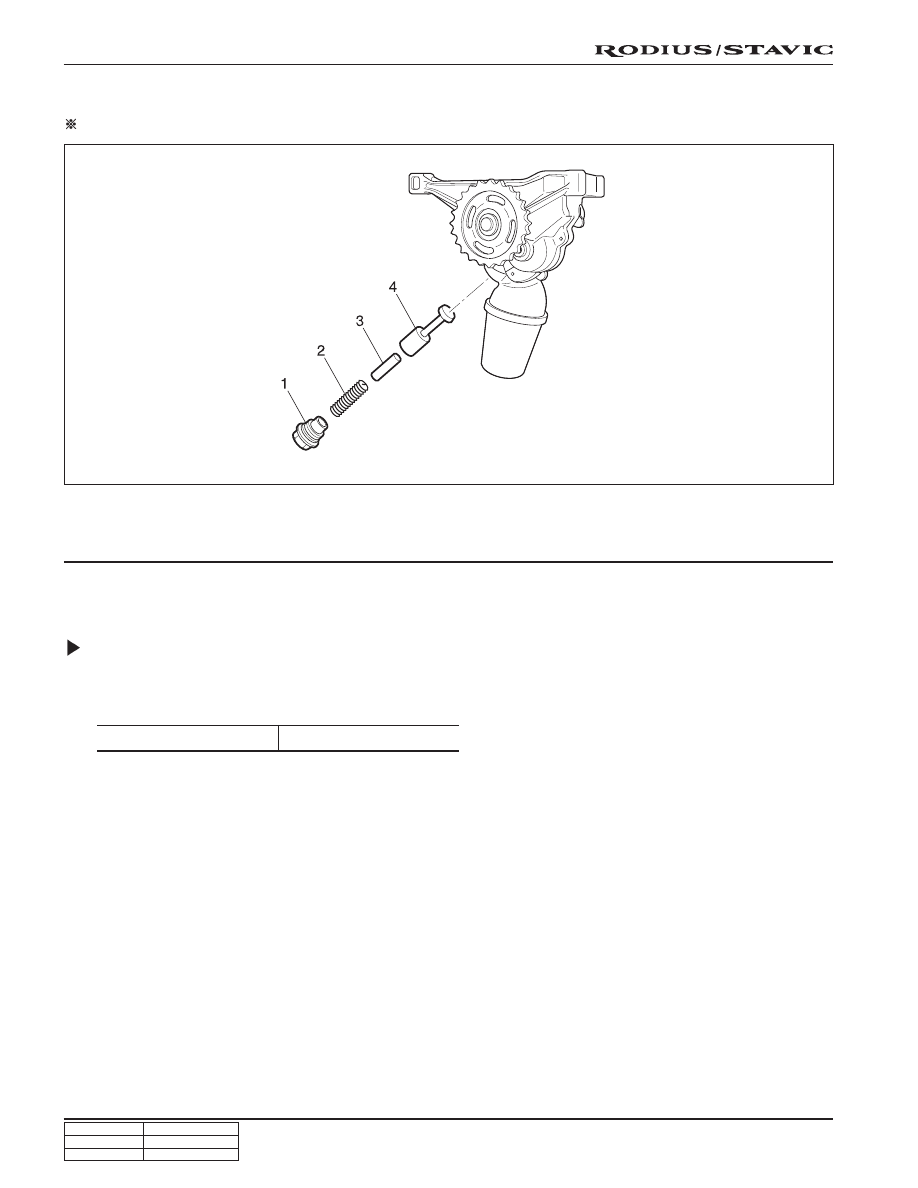

OIL PRESSURE RELIEF VALVE

Preceding Work: Removal of oil pan

1. Screw plug .................................. 50 Nm (37 lb-ft)

2. Compression spring

Removal & Installation Procedure

1. Remove the screw plug (1).

Installation Notice

2. Remove the spring (2), guide pin (3) and the piston (4).

3. Installation should follow the removal procedure in the

reverse order.

Notice

Don’t use the seal for the screw plug.

3. Guide pin

4. Piston

Tightening torque

50 Nm (37 lb-ft)