SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 2

1A-3

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

M162 GSL ENG SM - 2005.7

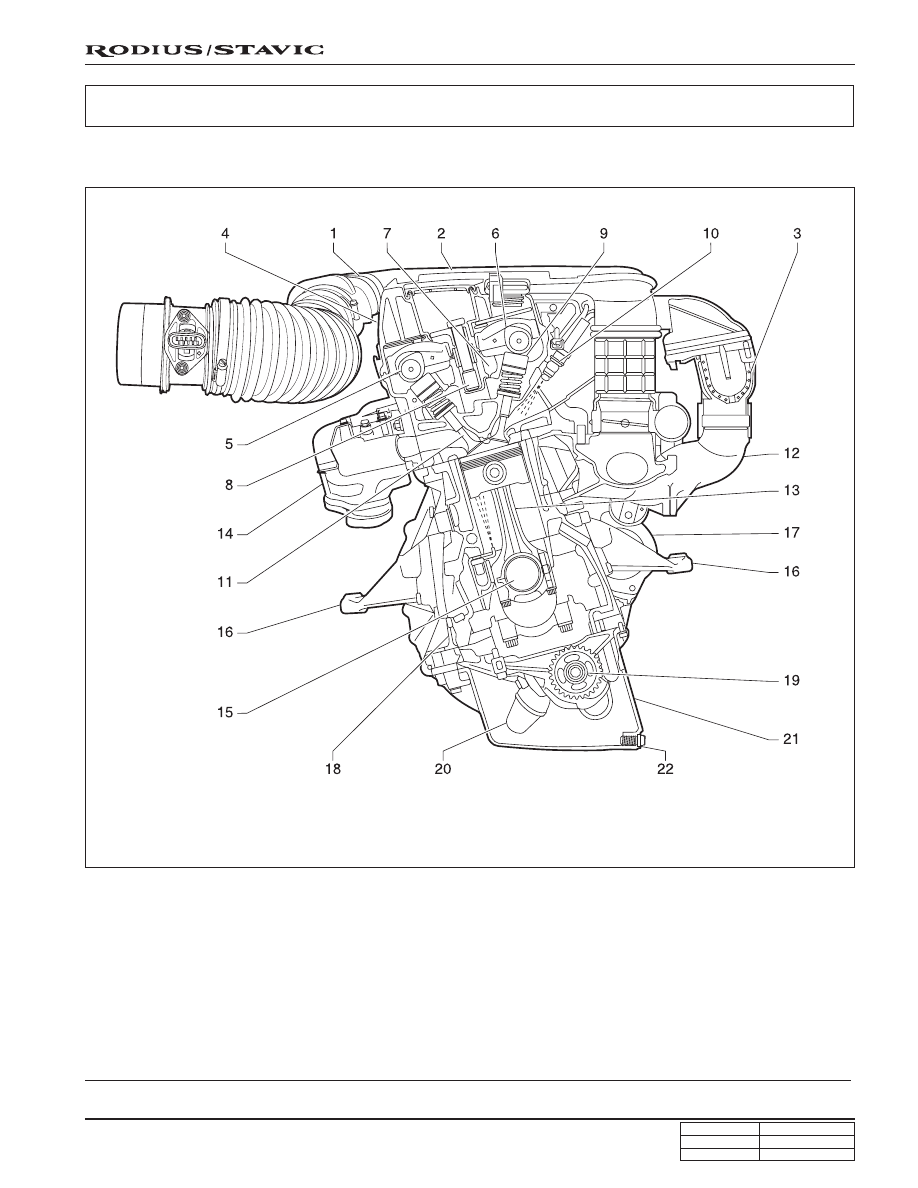

1. HFM sensor

2. Intake air duct

3. Resonance flap

4. Cylinder head cover

5. Exhaust camshaft

6. Intake camshaft

7. Cylinder head

8. Spark plug connector

COMPONENT LOCATOR

FRONT VIEW

9. Valve tappet

10. Injector

11. Exhaust valve

12. Intake manifold

13. Connecting rod

14. Exhaust manifold

15. Crankshaft

16. Engine mounting bracket

17. Starter

18. Crankcase

19. Oil pump sprocket

20. Oil strainer

21. Oil pan

22. Drain plug