SsangYong Korando III (2010 year). Manual - part 245

11-26

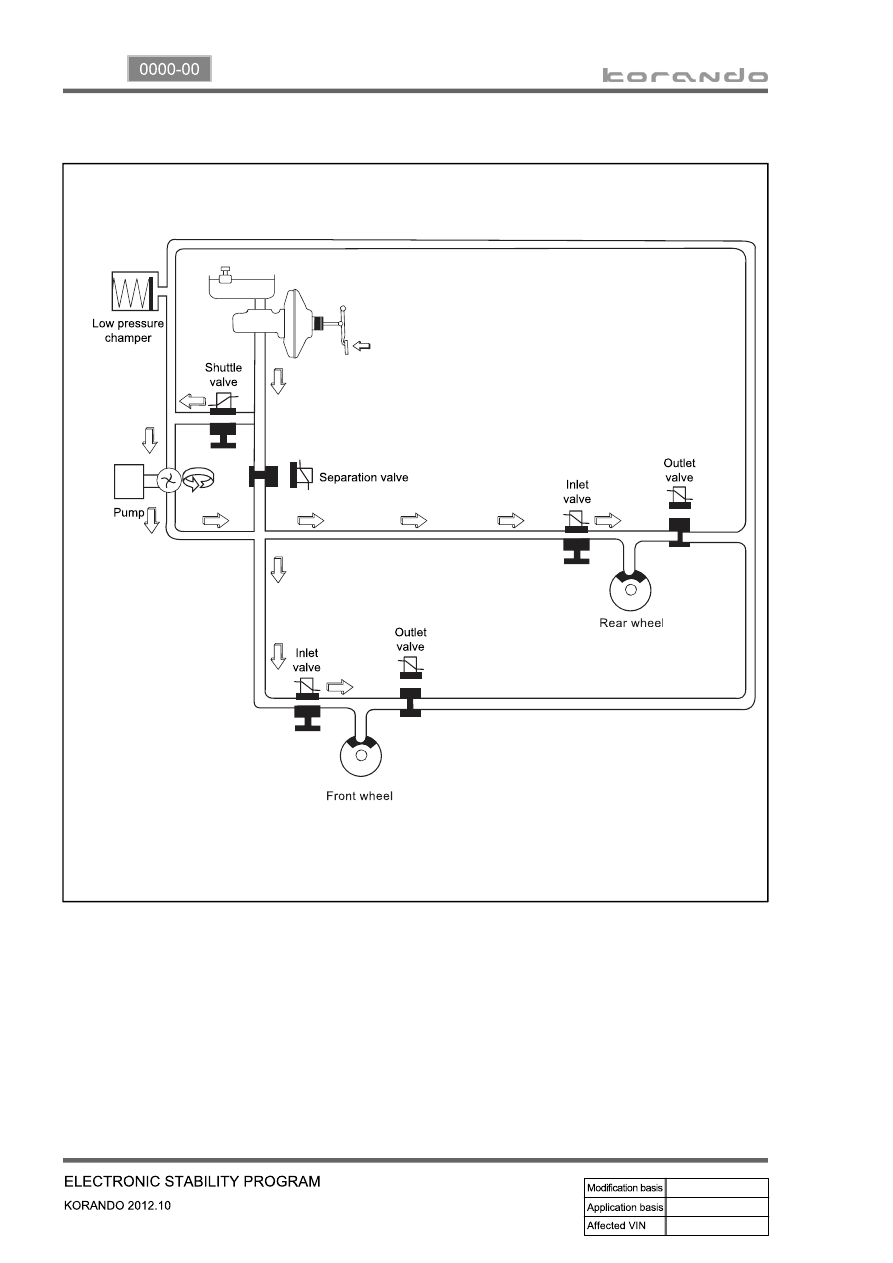

5) Hydraulic Circuit of HBA

The above figure shows one front and one rear wheel and the same hydraulic circuit forms as in the ESP

operation. When HECU recognizes that it is an emergency and it is required for hard braking, depending

on the pressure value of the brake pressure sensor and pressure changes caused by the pressure sensor

timing, it operates the pump immediately to apply the brake pressure at the wheels. Then, the pressure in

the pump increases until just before the corresponding wheel gets locked. The motor still keeps rotating

and the outlet valve and the separation valve will stay closed. When the wheel starts to lock, the HBA

function cancels and switches to ABS operation.