SsangYong Korando III (2010 year). Manual - part 212

02-12

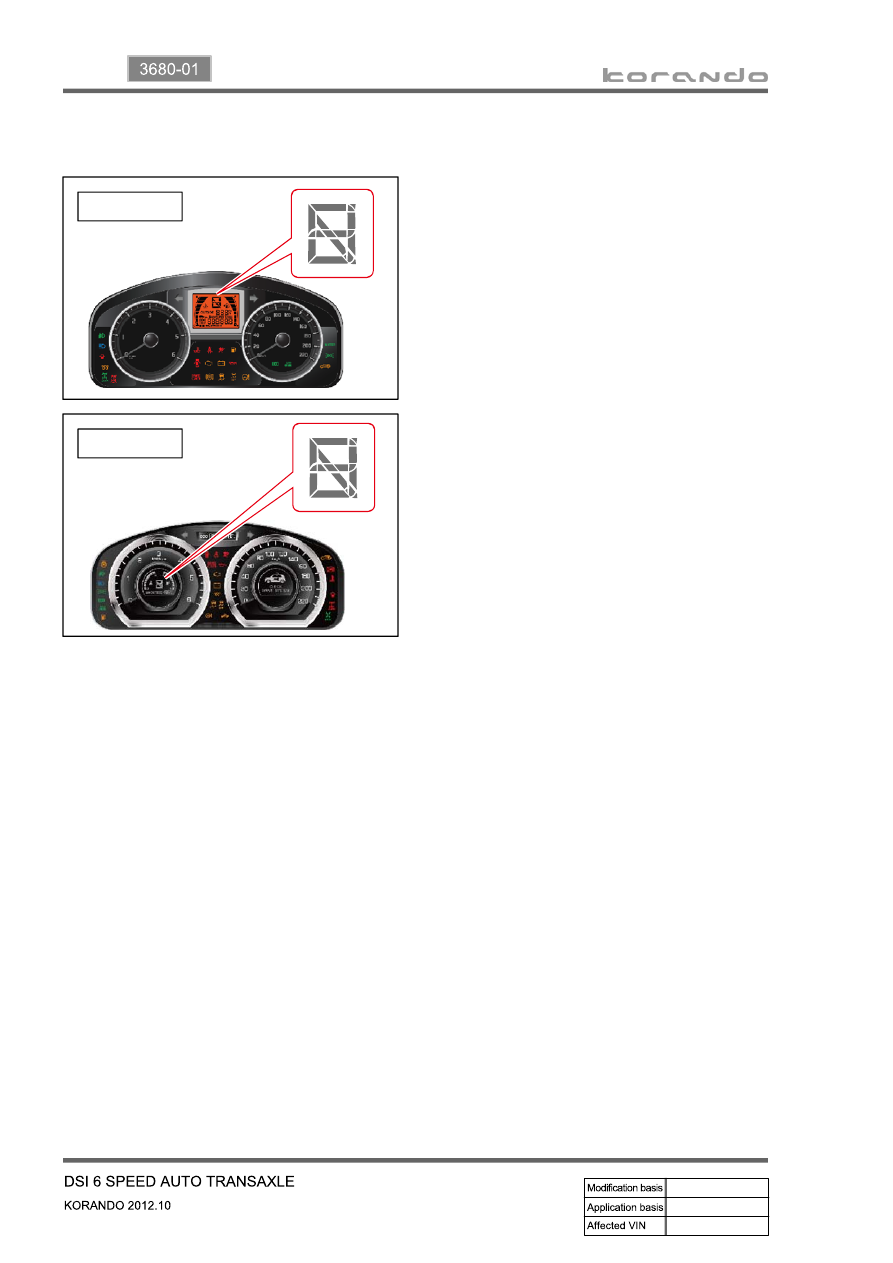

1st Gear State

▶

The 1st gear state will display on the

instrument cluster. Unlike the normal 1st gear,

engine braking will be available in this manual

1st state.

-

2nd Gear State

▶

The 2nd gear state will display on the

instrument cluster. 2-1 automatic kick-down

shifts are available. 2nd gear has engine

braking available.

-

3rd Gear State

▶

The 3rd gear state will display on the

instrument cluster. 3-2 and 3-1 automatic

kick-down shifts are available. 3rd gear has

engine braking available.

-

4th Gear State

▶

The 4th gear state will display on the

instrument cluster. 4-3 and 4-2 automatic

kick-down shifts are available. 4th gear has

engine braking available.

-

5th Gear State

▶

The 5th gear state will display on the

instrument cluster. 5-4 and 5-3 automatic

kick-down shift is available. 5th gear has

engine braking available.

-

6th Gear State

▶

The 6th gear state will display on the

instrument cluster. 6-5 and 6-4 automatic

kick-down shifts are available. 6th gear has

engine braking available.

-

STD type

SVC type