SsangYong Korando III (2010 year). Manual - part 72

15-10

(2) Fuel Control

a. Fuel Pressure Control Elements

Pressure control consists of 2 principles.

Determines rail pressure according to engine operating conditions.

Controls IMV to make the rail pressure to reach to the required value.

-

-

Pressure in the fuel rail is determined according to engine speed and load on the engine.

When engine speed and load are high

The degree of turbulence is very great and the fuel can be injected at very high pressure in order to

optimize combustion.

When engine speed and load are low

The degree of turbulence is low. If injection pressure is too high, the nozzle's penetration will be

excessive and part of the fuel will be sprayed directly onto the sides of the cylinder, causing

incomplete combustion. So there occurs smoke and damages engine durability.

-

-

Fuel pressure is corrected according to air temperature, coolant temperature and atmospheric pressure

and to take account of the added ignition time caused by cold running or by high altitude driving. A

special pressure demand is necessary in order to obtain the additional flow required during starts. This

demand is determined according to injected fuel and coolant temperature.

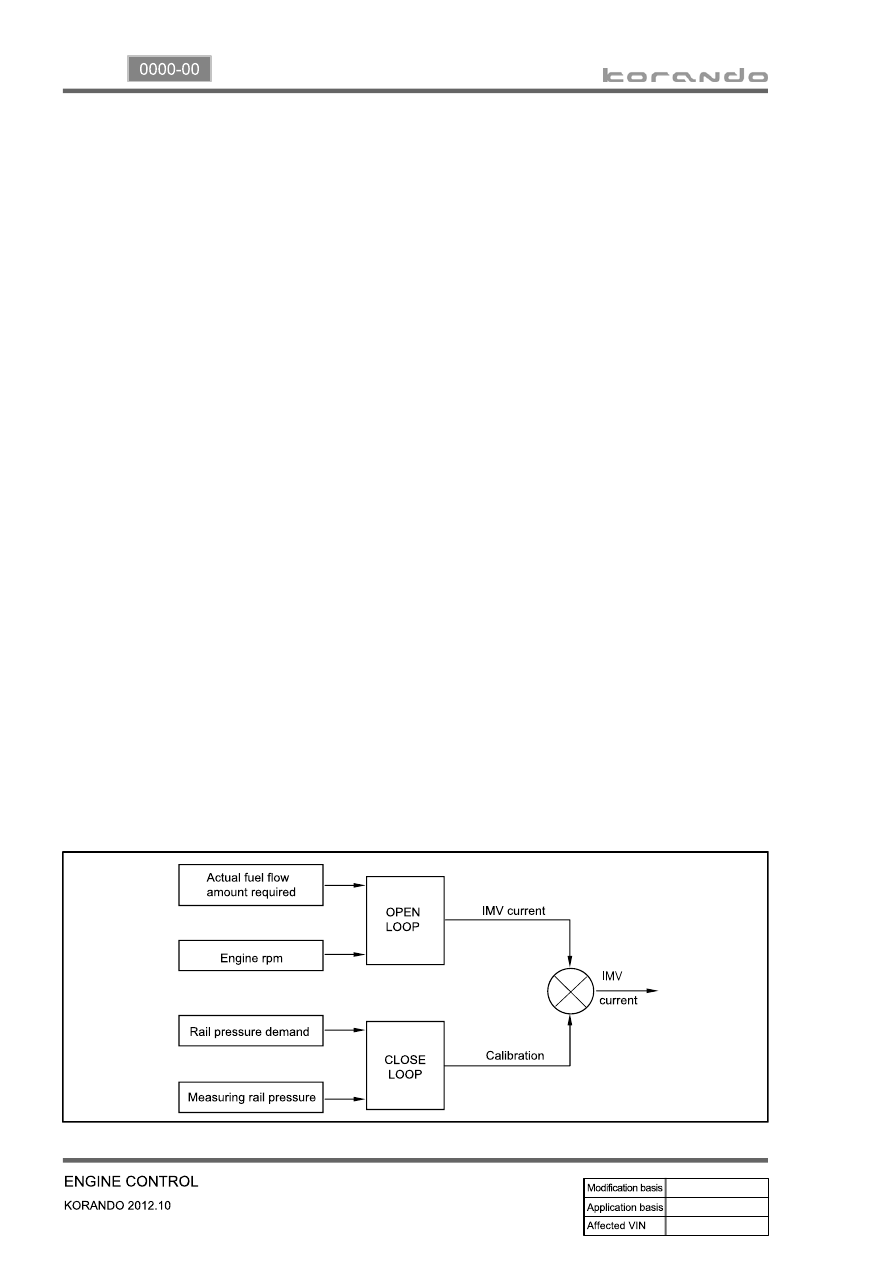

b. Fuel Pressure Control

Open loop determines the current which needs to be sent to the actuator in order to obtain the flow

demanded by the ECU.

▶

Closed loop will correct the current value depending on the difference between the pressure demand

and the pressure measured.

▶

If the pressure is lower than the demand, current is reduced so that the fuel sent to the high pressure

pump is increased.

If the pressure is higher than the demand, current is increased so that the fuel sent to the high

pressure pump is reduced.

-

-

Rail pressure is controlled by closed loop regulation of IMV.