SsangYong Korando II (1996-2006 year). Manual - part 452

SSANGYONG MY2002

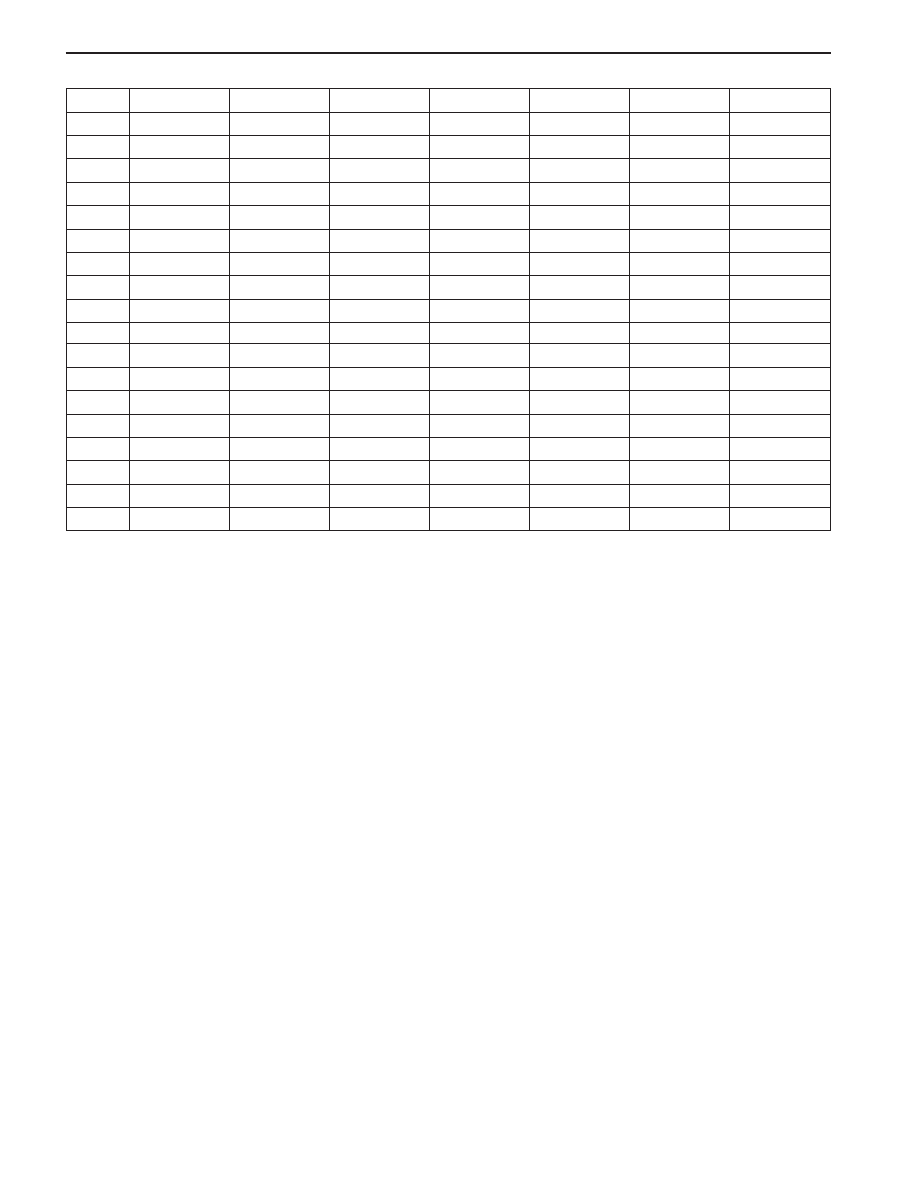

9N-4 FRAME AND UNDERBODY

1

2

3

4

5

6

7

S8

9

10

11

12

13

14

15

X16

17

18

Size

910

674

570

113

644

7.5

350.5

315

71.2

460

722.8

681

1250

47

218

1035

722

290

No

19

21

22

23

24

Y25

A26

27

28

29

X30

31

32

33

34

35

36

37

Size

355

1250

1300

1040

320

575

265

291.5

420.5

800

2725

170

510

90

1200

875

1010

700

No

38

39

40

41

42

43

X44

45

46

S47

48

49

S50

S51

H52

X53

54

55

Size

710

1305

1314

2367

102

204

625

50

99

396

200

24

231

178.5

251

290

137

47

No

56

57

H58

S59

K60

K61

62

63

X64

A65

A66

A67

68

X69

70

71

Size

232

166

65.8

1085

7.5

18.2

13

163

2335

425

485

675

215

3110

79.8

85

(mm)