SsangYong Korando II (1996-2006 year). Manual - part 318

AUTOMATIC TRANSMISSION 5A-175

SSANGYONG MY2002

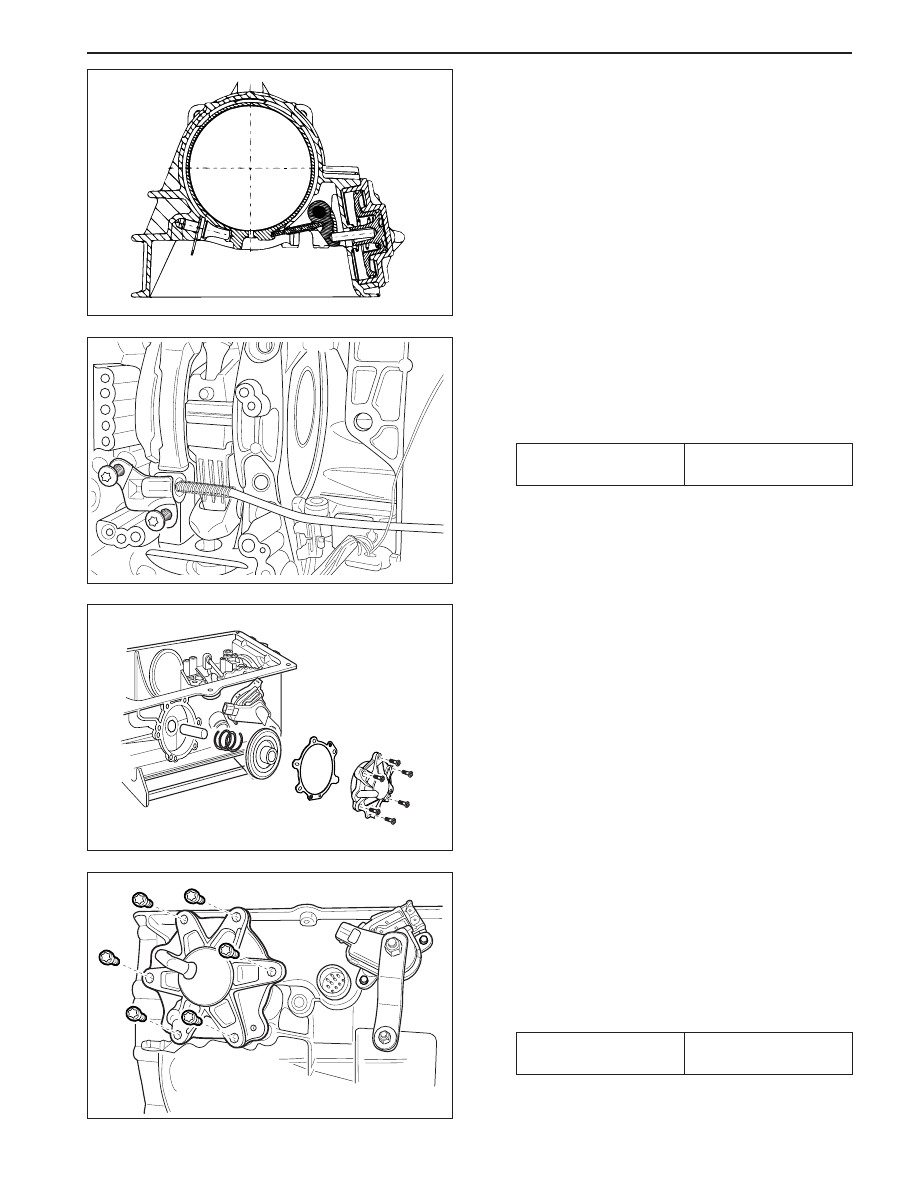

Rear Band Assembly

1. Check the rear band for any cracks or damage

along the lining and metal backing.

2. Install the reaction anchor strut into the main case,

without shims.

3. Carefully install the rear band into the transmission

case and ensure that it is properly fitted in the

case.

Notice: If fitting a new band, soak the new band in

automatic transmission fluid for a minimum of five

minutes prior to assembly.

4. Position the apply strut on the rear band then

engage the apply strut in the servo lever.

5. Install the cam plate and tighten the screws to

specification.

Installation Notice

Rear Servo Assembly

1. Check the servo piston ‘O’ rings and gasket for

any damage.

2. L u b r i c a t e t h e s e r v o p i s t o n ‘ O ’ r i n g s w i t h

automatic transmission fluid, and fit the ‘O’ rings

to the piston grooves.

3. Assemble the piston to the cover, ensuring that

‘ O ’ r i n g c o m p r e s s i o n i s a d e q u a t e b u t n o t

excessive.

4. Align the spring on the piston spigot, then position

the rear servo rod into the spigot.

5. Assemble the gasket to the cover and fit the

assembly to the case.

Notice: Do not use petroleum jelly on the gasket.

6. Apply additional Loctite 202 or equivalent as

required to the rear servo to case bolts. Install

the bolts and tighten to specification.

Installation Notice

KAA5A950

KAA5A960

KAA5A630

KAA5A990

Tightening Torque

30 - 35 N•m

(22 - 26 lb-ft)

Tightening Torque

16 - 22 N•m

(12 - 16 lb-ft)