Dacia Solenza (engine E7J). Manual - part 101

42

42 - 4

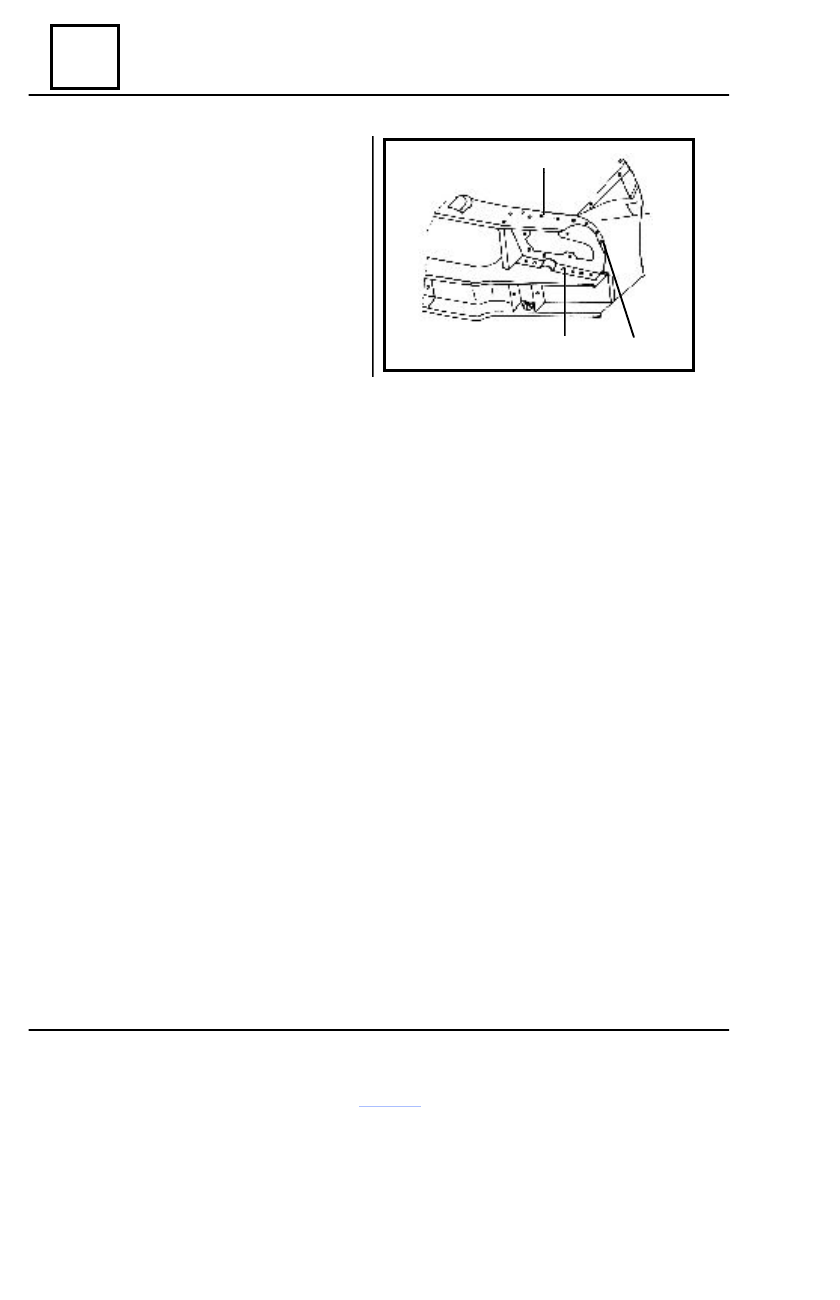

FRONT UPPER STRUCTURE

Headlamp support

7

8

6

DISMOUNTING

Dismount the elements, which are in contact

with the headlamp support.

Detach the welding points of the headlamp

support (2), which are in connection with :

- front wing lining in the area (6)

- radiator upper cross member in the area (7);

- front cross member in the area (8).

Straighten the areas resulted by dismounting.

Grind the areas resulted by dismounting.

REMOUNTING

Position and center the new element.

Check the correct positioning of the headlamp support.

Weld the headlamp support (2) following the welding outlines (6), (7) and (8).

Protect the welding with a corrosion-preventing product.

Mount the elements, which are in connection with the headlamp support, by performing the

dismounting operations in the reverse order.