Dacia Pick-Up 1304/1305/1307. Manual - part 120

AIR CONDITIONING

62

62 - 8

Compressor is absorbing the vapors coming from the evaporator at low pressure and tem-

perature, is compressing them and convey the gas at high temperature and pressure to the con-

denser.

The compressor is type Harrison V5, alternating, with pistons and variable cylinders capacity.

Compressor oil used PAG SP 10

Quantity of compressor oil used 265 cmc

The compressor is mounted on the left side of the engine block by means of two supports.

ATTENTION !

During handling the compressor oil, reduce to minimum the oil contact with the air,

which contains moisture.

D

ISMO UNTING

Disconnect the battery.

Drain the refrigerant circuit.

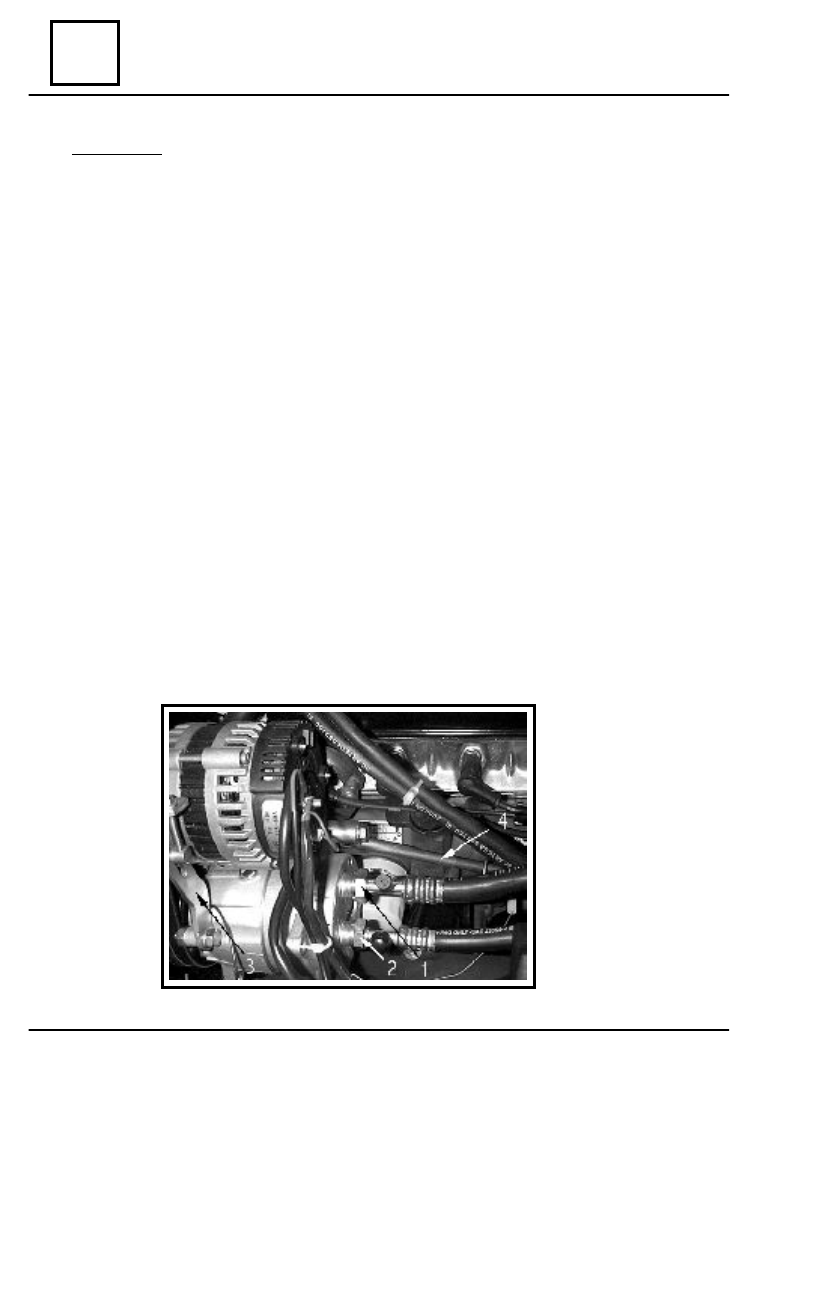

Disconnect the pipes (1) and (2) from the compressor.

Dismount the tensioning clip (3) and the alternator belt.

Disconnect the electric connectors of the alternator and the electric connector of the com-

pressor.

Dismount the alternator attachment screw on the support and detach the alternator.

Dismount the compressor tie rod (4).

Dismount the compressor attachment screws on supports.

Dismount the compressor.

COMPRESSOR