Dacia Pick-Up 1304/1305/1307. Manual - part 59

MANUAL GEARBOX

21

21 - 42

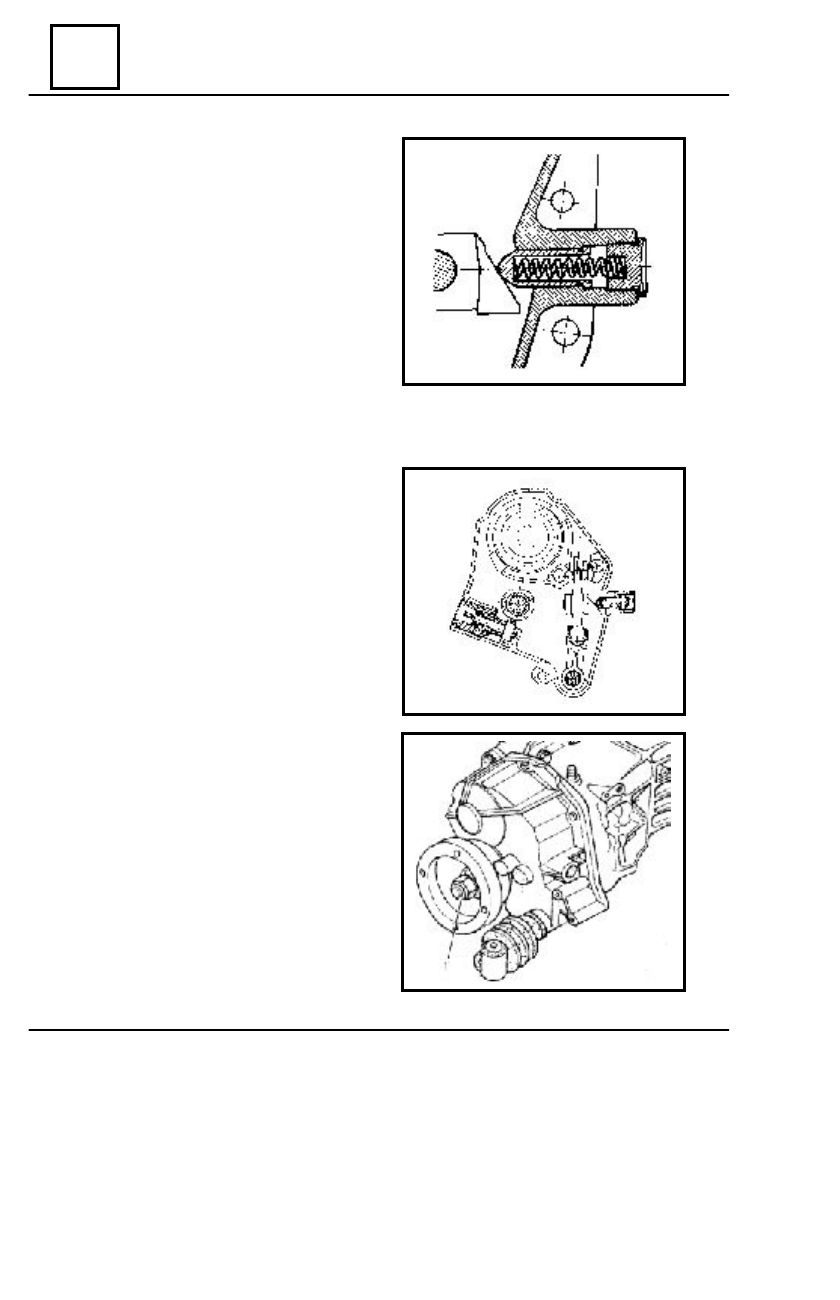

Mount the speedometer pinion and its guide

provided with a sealing gasket.

Mount :

- the velocity step V pusher;

- the spring;

- the gasket;

- the plug greased with LOCTITE 577

and tighten at the required couple (1,1-1,5daNm)

Bring the forks to the dead point.

Place the back cap gasket lubricate with

oil.

Place the back cap; position the velocity steps

selector in the forks shafts notches.

Tighten at the required moment

(1- 1,4daNm) the back cap attachment screws.

For G.B. 50C and 51C:

Fill the contact surface between the annular

seal and the flange with grease UM 170 Li Ca

Pb 2M.

Mount the flange of propeller shaft

transmission.

Place the washer and tighten at required

moment (10 - 12daNm) the flange attachment

nut (1).

REPAIR

BACK CAP RE MOUNTING