Renault Scenic 3 Chassis. Manual - part 7

31A

-

4

FRONT AXLE ASSEMBLIES

Brake calliper

31A

When replacing brake pads or a disc, be sure to re-

place the pads or disc on the opposite side.

REMOVAL

Mount the vehicle on a two post lift.

Fit the pedal press tool to the brake pedal to restrict

the outflow of brake fluid.

Unlock the steering wheel.

Remove the front wheels.

Undo the brake hose from the brake calliper.

Remove:

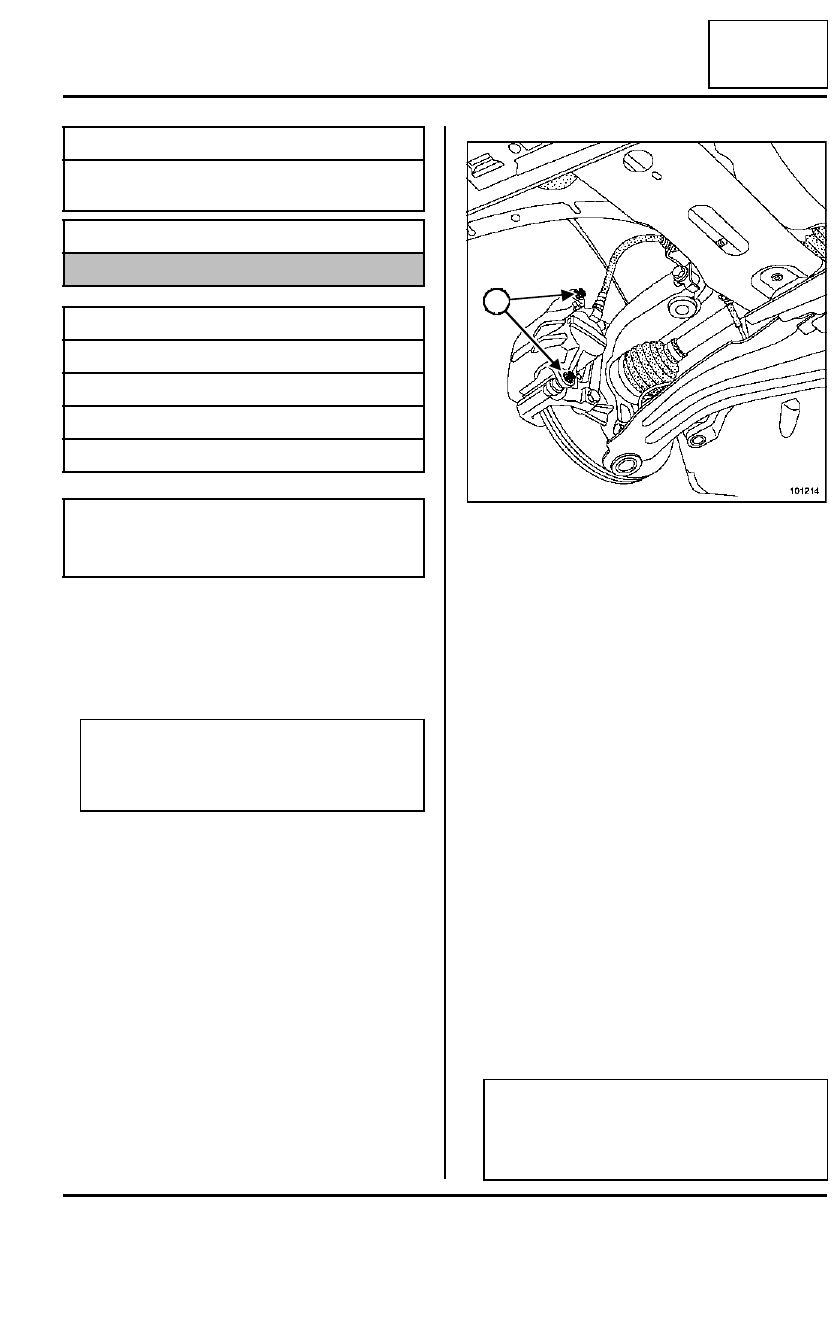

- the two guide pin bolts (1),

- the brake calliper,

- the brake pads,

Check the condition of the braking components (re-

place faulty parts).

Clean the calliper supports and callipers.

REFITTING

Push the piston back using tool (Fre. 1190-01) until

it is at the end of its bore.

Fit the pads, starting with the inside.

Refit:

- the calliper,

- the guide pin bolt.

Torque tighten:

- the guide pin bolts (3.2 daNm),

- the brake hose (1.7 daNm).

Special tooling required

Fre. 1190-01

Tool for pushing calli-

per pistons back

Equipment required

pedal press

Tightening torques

m

guide pin bolts

3.2 daNm

brake hose

1.7 daNm

bleed screw

0.65 daNm

wheel bolts

13 daNm

Note:

The callipers supplied as replacement parts are

pre-filled.

WARNING

Prepare for brake fluid outflow, to prevent

damage to the mechanical parts and bodywork

around the braking system.

101214

WARNING

- Mount the brake hose and wheel speed sensor

wiring, if they have been unclipped.

- Do not twist the brake hose.

1