Chrysler Cirrus, Dodge Stratus, Plymouth Breeze Haynes. Manual - part 2

0-12

Maintenance techniques, tools and working facilities

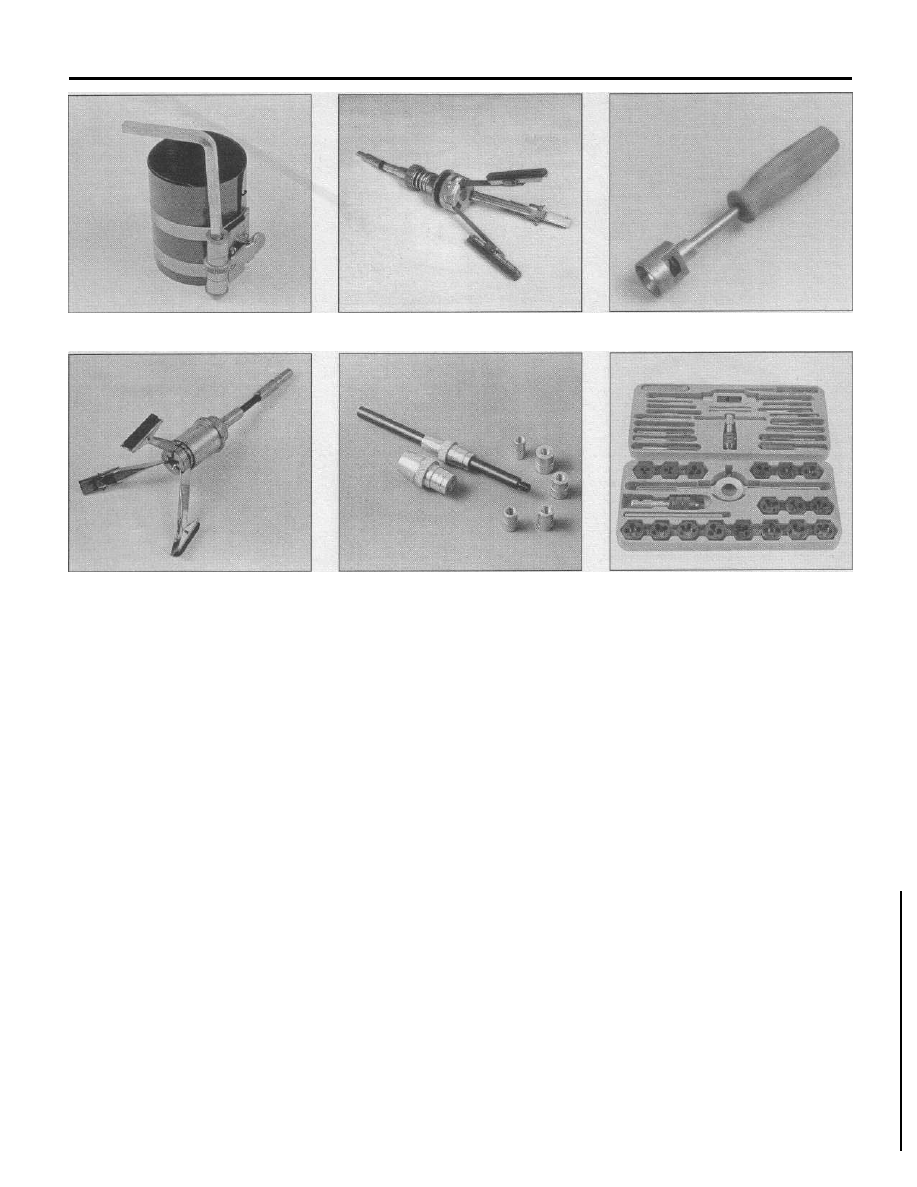

Ring compressor

Cylinder hone

Brake hold-down spring tool

Brake cylinder hone

should start off with the maintenance and

minor repair tool kit, which is adequate for

the simpler jobs performed on a vehicle.

Then, as confidence and experience grow,

the owner can tackle more difficult tasks,

buying additional tools as they are needed.

Eventually the basic kit will be expanded into

the repair and overhaul tool set. Over a period

of time, the experienced do-it-yourselfer will

assemble a tool set complete enough for

most repair and overhaul procedures and will

add tools from the special category when it is

felt that the expense is justified by the fre-

quency of use.

Maintenance and minor repair

tool kit

The tools in this list should be consid-

ered the minimum required for performance

of routine maintenance, servicing and minor

repair work. We recommend the purchase of

combination wrenches (box-end and open-

end combined in one wrench). While more

expensive than open end wrenches, they

offer the advantages of both types of wrench.

Combination wrench set (1/4-inch to

1 inch or 6 mm to 19 mm)

Adjustable wrench, 8 inch

Spark plug wrench with rubber insert

Spark plug gap adjusting tool

Feeler gauge set

Brake bleeder wrench

Standard screwdriver (5/16-inch x

6 inch)

Clutch plate alignment tool

Phillips screwdriver (No. 2 x 6 inch)

Combination pliers - 6 inch

Hacksaw and assortment of blades

Tire pressure gauge

Grease gun

Oil can

Fine emery cloth

Wire brush

Battery post and cable cleaning tool

Oil filter wrench

Funnel (medium size)

Safety goggles

Jackstands (2)

Drain pan

Note: If basic tune-ups are going to be part of

routine maintenance, it will be necessary to

purchase a good quality stroboscopic timing

light and combination tachometer/dwell

meter. Although they are included in the list

of special tools, it is mentioned here because

they are absolutely necessary for tuning most

vehicles properly.

Repair and overhaul tool set

These tools are essential for anyone

who plans to perform major repairs and are in

addition to those in the maintenance and

minor repair tool kit. Included is a compre-

hensive set of sockets which, though expen-

sive, are invaluable because of their versatil-

ity, especially when various extensions and

drives are available. We recommend the 1/2-

inch drive over the 3/8-inch drive. Although

the larger drive is bulky and more expensive,

Tap and die set

it has the capacity of accepting a very wide

range of large sockets. Ideally, however, the

mechanic should have a 3/8-inch drive set

and a 1/2-inch drive set.

Socket set(s)

Reversible ratchet

Extension - 10 inch

Universal joint

Torque wrench (same size drive as

sockets)

Ball peen hammer - 8 ounce

Soft-face hammer (plastic/rubber)

Standard screwdriver (1/4-inch x 6 inch)

Standard screwdriver (stubby -

5/16-inch)

Phillips screwdriver (No. 3 x 8 inch)

Phillips screwdriver (stubby - No. 2)

Pliers - vise grip

Pliers - lineman's

Pliers - needle nose

Pliers - snap-ring (internal and external)

Cold chisel - 1/2-inch

Scribe

Scraper (made from flattened copper

tubing)

Centerpunch

Pin punches (1/16, 1/8, 3/16-inch)

Steel rule/straightedge - 12 inch

Allen wrench set (1/8 to 3/8-inch or

4mmto10mm)

A selection of files

Wire brush (large)

Jackstands (second set)

Jack (scissor or hydraulic type)